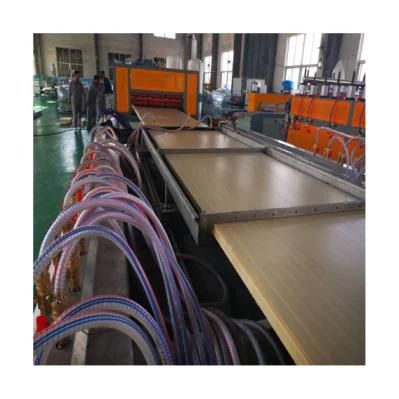

High Quality WPC Foam Board Machine/WPC Board Making Machine/Production Machine

Ningbo Easyget Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

WPC board finished products

Company Information

Qingdao Tongsan PLastic Machinery Co.,LTD

Qingdao Tongsan Plastic Machinery Co., LTD is a professional plastic extrusion machines manufacturer which stands by the Jiaozhou Bay. Converged with the national first-class scientific talests, our company is engaged in the study of new- type plastic machines and the conversion of international high-and -new technology. Cooperating with scientific research instifutions and institutions of higher education , we are converting the newest scientific payoffs at top speed. We will supply you the high-performance and high-tech plastic machines, Hollow sheet machine, Corrugated pipe machine, PVC and WPC foam board making machine.

Why Choose Us?

Be Our Client:

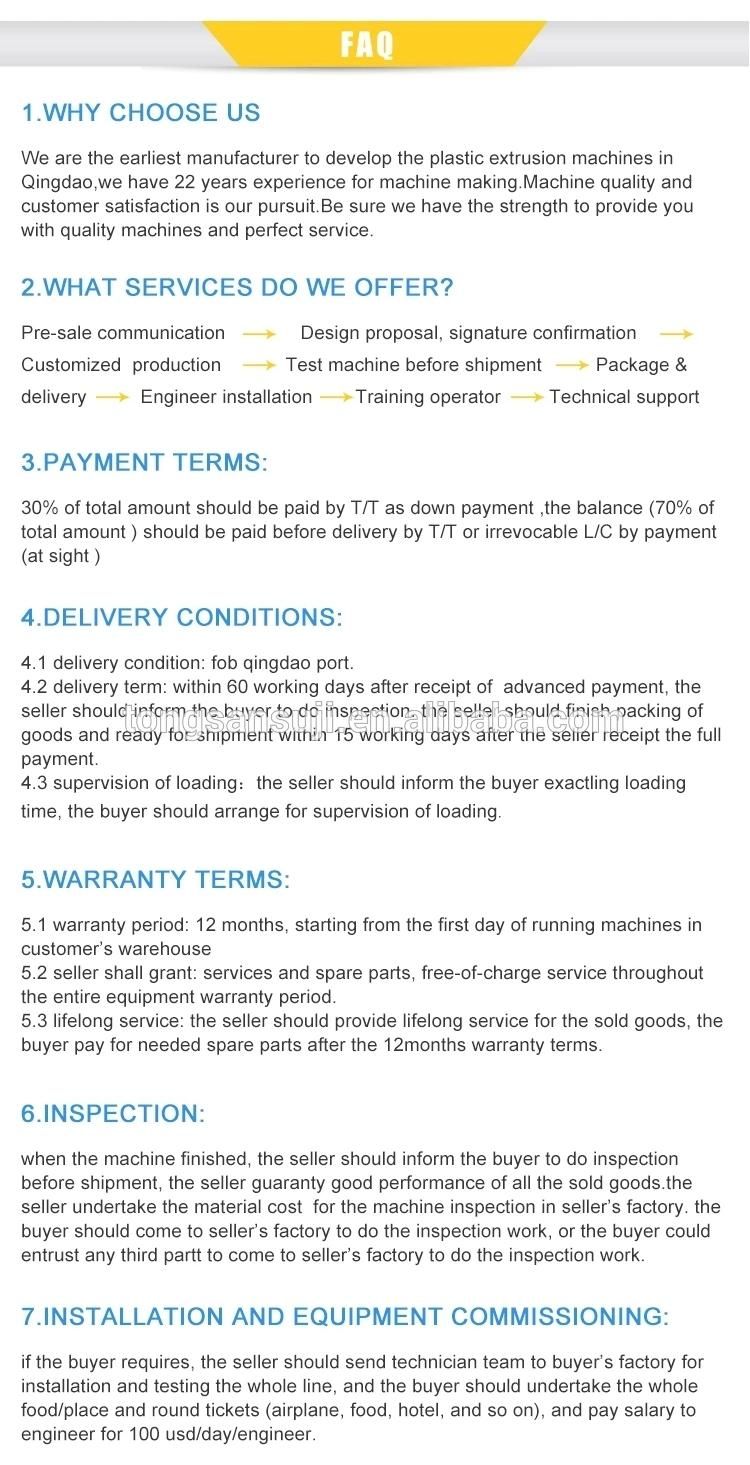

FAQ:

Packaging & Shipping Fastening of fixed Steel Wire with plastic Film wound Wood Block

Our Services

- We will provide the Feasibility Analysis Report for the wood plastic project.

- We will provide the model selection and technical parameter for wood-plastic machine.

- We will provide the design for the plant and electric powder accounting for the facilities.

- We will provide the design for wood plastic formula according to the product requirement.

- We will provide the technology of wood plastic product surface treatment.

- We will provide technique training for operator.

- We will provide solution for the practical problem during the production.

- We will install and test machine for free.

- We will provide turnkey project to customers.

Contact me

We look forward to have the opportunity to work together with you in the future.

Alan Jia

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23