WPC Plate Production Line, PVC Foam Sheet Machine

Kunshan Canuri Precision Tools Co., Ltd. / 2022-07-04

=== Base Info ===

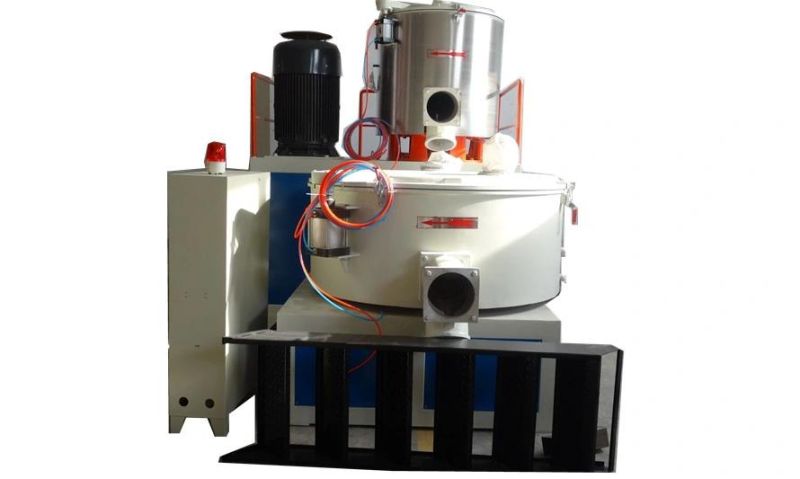

=== Description === Heat/cooling Mixer:

Heat/cooling Mixer:

Material mixer consists of heat mixing barrel (upper)and cooling mixing barrel(lower). Spring up loader:

Spring up loader:

Automatic spring up loader springs up the processed material to silo(hopper as shown).  Conical twin-screw extruder:

Conical twin-screw extruder:

T-MOULD:

T-MOULD:

Calibration platform:

Calibration platform:

Cooling Bracket:

Cooling Bracket:

The cooling bracket is to cool down the board from calibration platform Haul off system:

Haul off system:

The haul off system is to haul the line forward. Side trimming device:

Side trimming device:

Side trimming device is to trim the side of board. Blade cutter:

Blade cutter:

Blade cutter is to cut board in our set length by transverse blade. And stacker follows the cutter to pick the board automatically.

Parameter of main machines

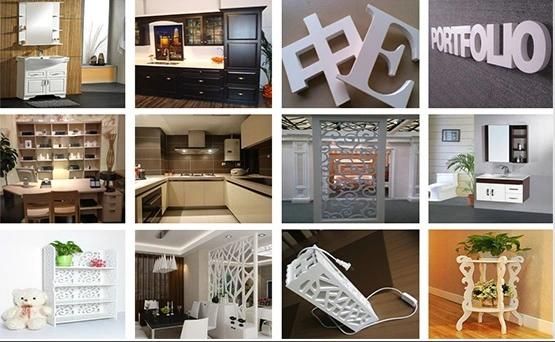

Advantage of PVC WPC foam board:1)Widely resource and 100% recyclable, enviromental-friendly2)Water proof, insect proof, mildew proof, weathering resistant, flame retardant, acid and alkali resistant, sound separation and absorbing3)good stability, no crack, no deformation and sawing, neil,drilling,welding, bonding can be conducted as wooded material4)suitable for thermal bending and shaping to get designated style5)light for transport and storage6)non toxic, no formaldehyde, no benzene7)surface is smooth and suitable for printing, embossing, heat transfer printingApplication:1)outdoor advertising board, indoor decoration board, seperation of public buliding, dust-free room.2)building formwork, seashore waterproof facility, rot proof projject.3)bathroom cabinet, kitchen cabinet, household furniture, wardrobe, decorative shelf etc.

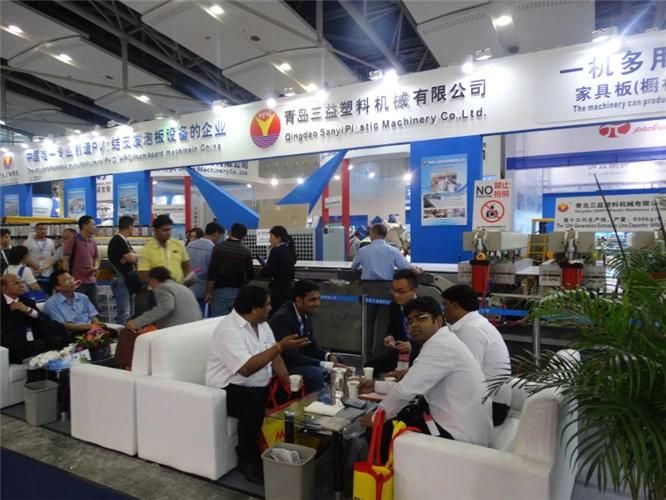

Company strength

Our servicePre-sale service:To help customers do market research, make project planning and production line matched requirements analysis.

After-sale service:To provide installation and test for the machine.

To provide formulas and technology of relevant products.

To provide information of chemical material manufactories.

To provide technical training for clients' employees.To direct technology aspect of relevant use according to customers' requirements

FAQ

Q1---Where is your factory located?

---Our factory is located in Qingdao City, Shandong Province

Q2---How many employees of your factory?

---We have about 100 staffs including the Production/R&D/Sales/Quality/Warehouse/After-Sales Service etc

Q3---Besides the PVC Plank Machine,if you also produce PVC Profile/Pipe etc

---No-We only focus on the PVC Plank Machine with at least 12 years experience

Q4---How many engineers in service?

---We have 11 professional engineers in service and they all have the passport

Q5---If you will start the machine before delivery?It's free or we need to pay?

---Of course,we must start the machine for your inspection until you satisfy with our machine and it's free

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23