PVC Wood-Plastic Profile Making Machine/UPVC Door Window Making Machine/Production Machine

Ningbo Easyget Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

1.WPC Granulation Machine

After get ready wood powder and recycled PP/PE plastic,The first step is mixing them with chemicals,The use WPC granulation machine to make WPC granules.

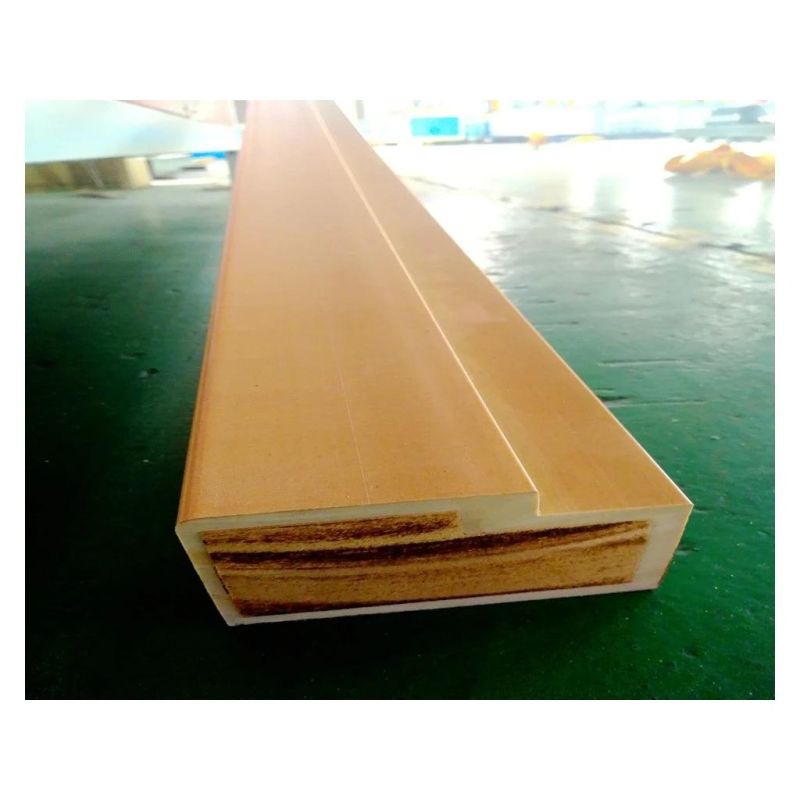

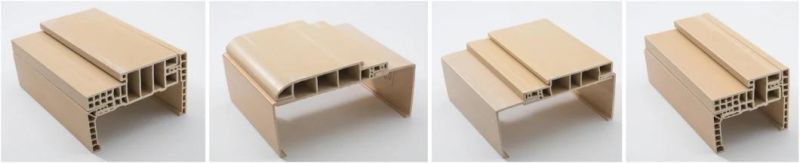

PP/PE/PVC wood plastic composite WPC profile making machine

PP/PE wpc profile making machine can continuously produce PP/PE WPC profile. Including PP/PE WPC decking floor, PP/PE WPC outdoor wall panel, PP/PE WPC fence , post and so on.

The customer can also use this line to produce PVC WPC window and door profile by changing the screw and mould.

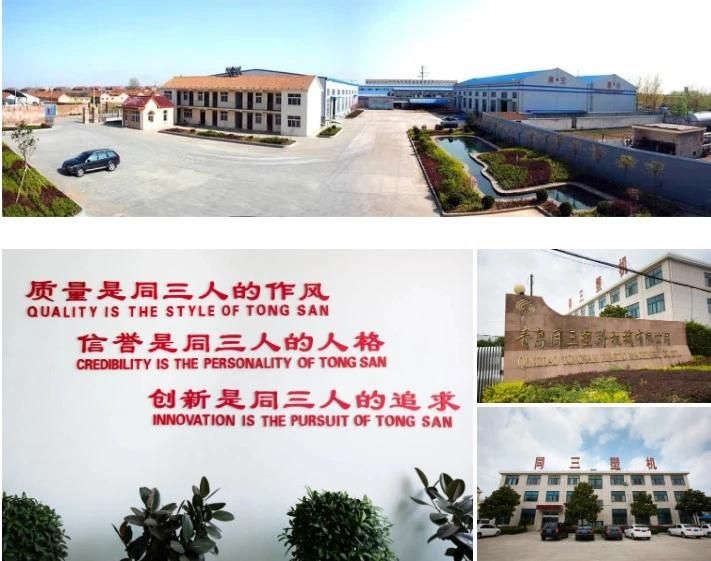

Company Information

Qingdao Tongsan PLastic Machinery Co.,LTD

Qingdao Tongsan Plastic Machinery Co., LTD is a professional plastic extrusion machines manufacturer which stands by the Jiaozhou Bay. Converged with the national first-class scientific talests, our company is engaged in the study of new- type plastic machines and the conversion of international high-and -new technology. Cooperating with scientific research instifutions and institutions of higher education , we are converting the newest scientific payoffs at top speed. We will supply you the high-performance and high-tech plastic machines, Hollow sheet machine, Corrugated pipe machine, PVC and WPC foam board making machine.

Packaging & Shipping

Fastening of fixed Steel Wire with plastic Film wound Wood Block

Our Services

- We will provide the Feasibility Analysis Report for the wood plastic project.

- We will provide the model selection and technical parameter for wood-plastic machine.

- We will provide the design for the plant and electric powder accounting for the facilities.

- We will provide the design for wood plastic formula according to the product requirement.

- We will provide the technology of wood plastic product surface treatment.

- We will provide technique training for operator.

- We will provide solution for the practical problem during the production.

- We will install and test machine for free.

- We will provide turnkey project to customers.

We look forward to have the opportunity to work together with you in the future.

Alan Jia

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23