Custom Machining Surface Casting Steel Agriculture Machine Ball Bearing Housing

Shenzhen Wing Tat Packing Co., Ltd / 2022-06-08

- Customized:Customized

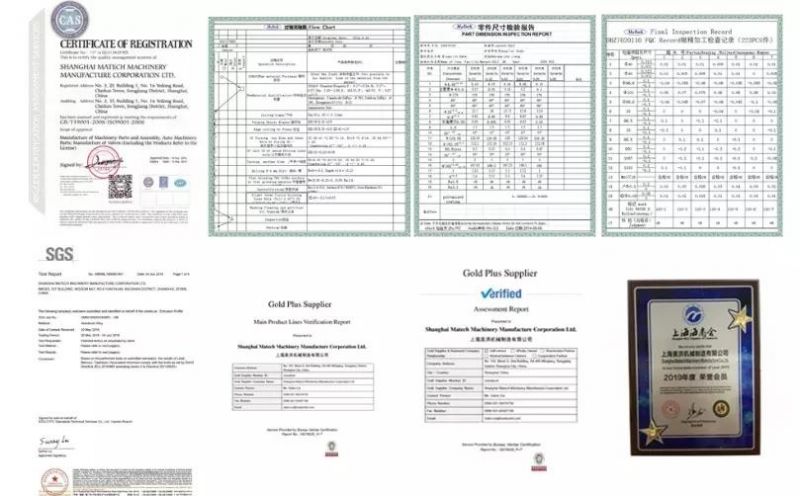

- Certification:CE, ISO, Ts16949

- Standard Parts:No

- Universal:No

- Type:Housing

- Material:Carbon Steel

=== Base Info ===

- Model NO.:Nonstandard

- Material Available:Wcb, G25crmo4, G35, G45

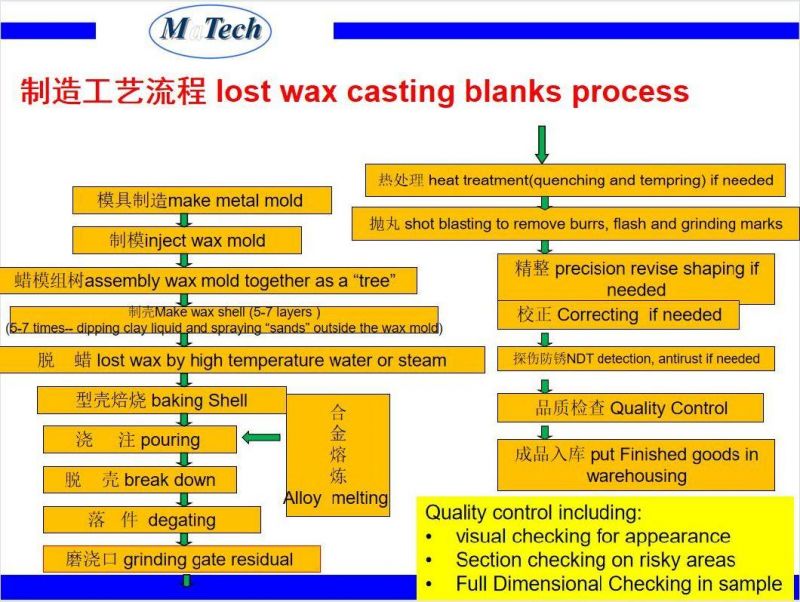

- Blank Process:Investment Casting, Option Lost Wax Casting

- Casting Tolerance:CT4-8 for Steel Casting

- Machining Process:CNC Machining, Lathing, Milling, Turning, Boring,

- Surface Finish Treatment:Dacromat Coating, Finish Painting

- Machining Tolearnce:From 0.005mm-0.01mm-0.1mm

- Machined Surface Quality:Ra 0.8-Ra3.2 According to Customer Requirement

- Package for Steel Casting:Multiplayer Wood Box with Big Plastic Bag Inside

- Lead Time:45 Days for Bearing Housing

- Service for Steel Casting:Metal Parts Solution as Per Customer′s Drawing

- Transport Package:Multiplayer Wood Box with Big Plastic Bag Inside

- Specification:Custom

- Trademark:Matech

- Origin:Zhejiang

- HS Code:8432900000

- Production Capacity:150 Tons,Month

=== Description ===

Item Name

General Products

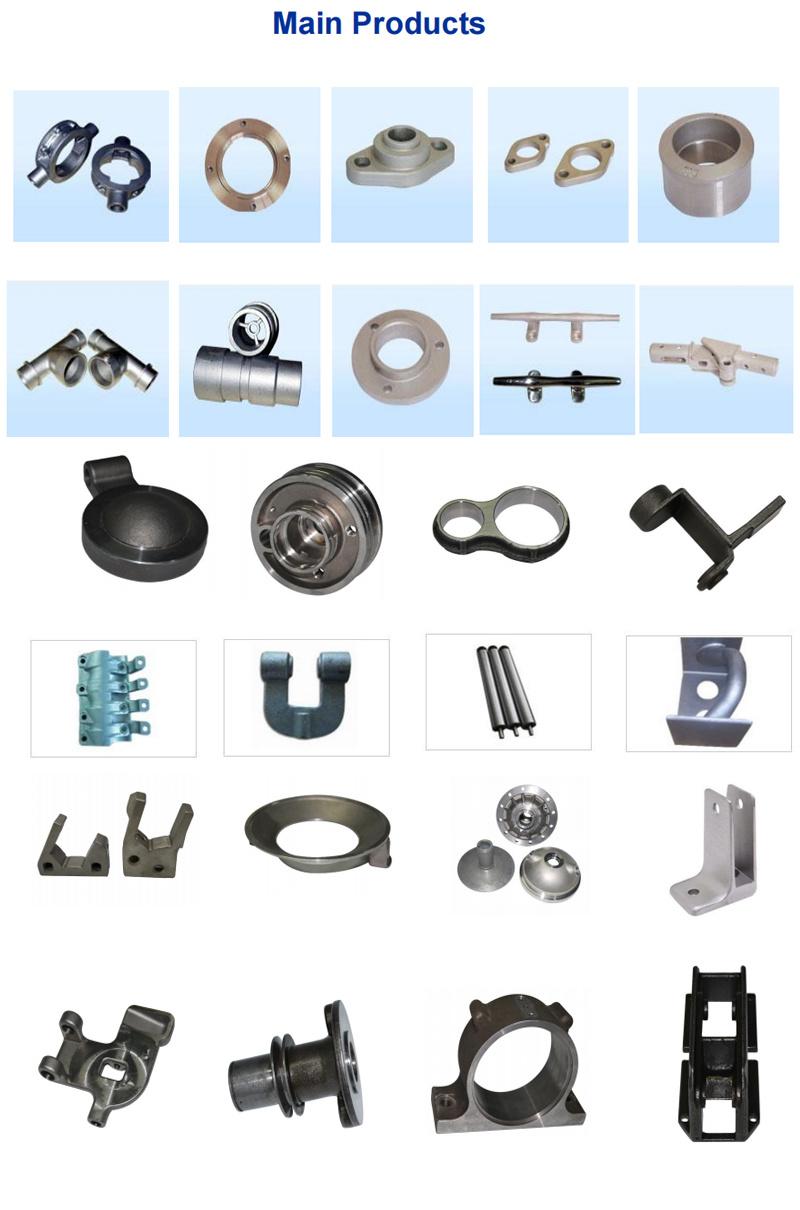

Application/Service Area

Metal Parts Solution for Vehicle, Agriculture machine, Construction Machine, transportation equipment, Valve and Pump system, Agriculture machine metal Parts, engine bracket, , gear cover, shaft, spline shaft , pulley, flange, connection pipe, valve housing ,Fitting , flange, wheel, etc.

Main blank Process for Steel Casting

Investment casting (wax mold made by middle temperature wax) /Precision casting ;

Lost Wax Casting (wax mold made by low temperature wax)/ Precision casting

Blanks Tolerance -Casting Tolerance

CT7-8 for Lost wax Casting Process

CT4-6 for Investment casting Process

Applicable Material

Carbon steel, Low Carbon steel, middle carbon steel,WCB, WCA, WCC, ISO 340-550, Alloy Carbon steel: G25CrMo4, Heat Resistant Steel,

Stainless Steel: CF8, CF8M, . G-X6CrNiMo1810, G-X7CrNiNb1189, SUS 304, 304L, 316, 316L.OR According to customer requirement

Casting Blank Size /Dimensions

2 mm-600mm / 0.08inch-24inch according to customer requirement

Casting Blank Weight

Range from 0.01kg-85kg

Applicable Machining Process

CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming /Grinding/Honing and etc.

Machining Tolerance

From 0.005mm-0.01mm-0.1mm

Machined Surface Quality

Ra 0.8-Ra3.2 according to customer requirement

Applicable Heat Treatment

Normalization , annealing, quenching and tempering, Case Hardening, Nitriding, Carbon Nitriding, Induction Quenching

Applicable Finish Surface Treatment

Shot/sand blast, polishing, Surface passivation, Primer Painting , Powder coating, ED- Coating, Chromate Plating, zinc-plate, Dacromat coating, Finish Painting,

MOQ

For stainless steel casting : 200pcs

For machining: 50pcs

Lead Time

45days from the receipt date of deposit for Lost Wax Casting

Technical Support:

Shanghai Matech is professional at independent development and design. Our engineers are skilled at AUTO CAD, PRO ENGINEER, SOLID WORKS and other 2D & 3D softwares. We are able to design, develop,produce and deliver your PO according to your drawings, samples or just an idea. Dural control of standard products and OEM products.

Quality Control:

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

Our Factory

Our FactoryShanghai Matech Machinery Manufacture Co., Ltd.

--Branch of Matech Industry Ltd.

We specialize in Metal Parts Solution for Vehicle, Agriculture machine, Construction Machine, transportation equipment, Valve and Pump system.

With keeping manufacturing process design, quality planning, key manufacturing processes and final quality control in house.

We are mastering key competence to supply quality mechanical parts and assembly to our customers for both Chinese and Export Market.

To satisfy different mechanical and functional requirements from our customers we are making a big range of metal products for our clients on base of different blanks solutions and technologies.

These blanks solutions and technologies include processes of Iron Casting, Steel Casting, Stainless Steel Casting, Aluminum Casting and Forging.

During the early involvement of the customer's design process we are giving professional input to our customers in terms of process feasibility, cost reduction and function approach.

You are welcome to contact us for technical enquiry and business cooperation.

Our Certificate

Our Customer

Our Team

Our Package

Inner Packing → Strong & waterproof plastic big is packed inside, to keep the product in safe condition.Or as customer requests.

Outer Packing →Multilayer wooden box with strong bandages, used for standard export package. Or customized as per customer's requirements.

FAQ

1Q: Are you trading company or manufacturer?

A: We are a factory, so we can provide competitive price and fast delivery for you.

2Q: What kind of service can you provide?

A: Our company can provide custom casting, CNC machining and surface treatment according to customer's requirements.

3Q: What's kinds of information you need for a quote?

A: In order to quote for you earlier, please provide us the following information together with your inquiry.

1. Detailed drawings (STEP, CAD, SOLID Works, PROE, DXF and PDF)

2. Material requirement (SUS, SPCC, SECC, SGCC, Copper, AL, ETC.)

3. Surface treatment (powder coating, sand blasting, planting, polishing, oxidization, brushing, etc.)

4. Quantity (per order/ per month/ annual)

5. Any special demands or requirements, such as packing, labels, delivery, etc.

4Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory, then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions (Thickness, Length, Height, Width), CAD or 3D file will be made for you if placed order.

5Q: What makes you different from others?

A: 1. Our Excellent Service

We will submit the quotation in 48 hours if getting detailed information during working days.

2. Our quick manufacturing time

For Normal orders, we will promise to produce within 3 to 4 weeks.

As a factory, we can ensure the delivery time according to the formal contract.

6Q: Is it possible to know how are my products going on without visiting your company?

A: We will offer a detailed production schedule and send weekly reports with photos or videos which show the machining progress.

7Q: Can I have a trial order or samples only for several pieces?

A: As the product is customized and need to be produced, we will charge sample cost, but if the sample is not more expensive, we will refund the sample cost after you placed mass orders.

8Q: Why there is tooling cost?

A: It's mold cost. Indispensable production process. Only need to pay for first order, and we will bear maintenance cost of mold damage.

9Q: What is your terms of payment?

A: Payment of sample order ≤ 1000USD, 100% T/T full payment.

Payment of tooling or batch order ≥ 5000USD, 70% T/T in advance, balance before shipment.

10Q: What's your after-sale service?

A: If there is quality problem, please provide photos or test report, we will replace defective goods or return funds.

If you have any other questions please find us online, or send messages via email, WhatsApp for better communication!

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23