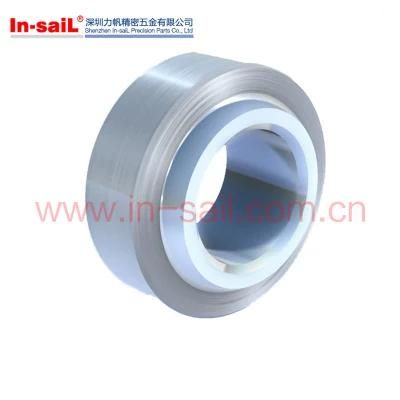

Stainless Steel Swivel Spherical Plain Bearing for Auto Part

Anhui Gangfa Printing Co., Ltd. / 2022-06-08

- Rolling Element:Single Row

- Structure:To The Heart

- Material:Stainless Steel

- Load Direction:Radial Spherical Plain Bearing

- Add Lubricant:Non Self-lubricating

- Application:Automation Equipment

=== Base Info ===

- Model NO.:OEM

- Model No.:Automation Components Linking Technology

- Series:Clevis,Joint,Bearing

- Surface Treatment:Anodizing, Polished, Powder Coating, etc

- Design:OEM Services Provided

- Inspection:100% QC Steps Inspect Before Shipment

- Manufacture Processing:CNC Maching,Casting,Stamping,Forging,Injection Mol

- Export Markets:Global

- Transport Package:PE Bag + Cartons, Blister Packing

- Specification:SGS, Material certification, DIN, ANSI, GB, JIS

- Trademark:In-saiL

- Origin:Shenzhen, China

- HS Code:7318160000

- Production Capacity:100k PCS,Week

=== Description ===

Production Capability

Product Details:

1.Standards:DIN, GB, BS, ANSI, ASME,JIS,ISO

2. Material:Stainless steel(SS304,SS316), carbon steel(C1022,1010,1008) copper, iron and so on.

3. Size: ST 2.9-6.3 #6--#14

4. Certificate: ISO9001:2000 RoHS certification

5. Features:Good anti-corrosion ability, kinds of coatings

6. Grade:4.8, 6.8, 8.8, 10.9, 12.9 A2-70 A4-80...

7. After-sale service:If any quality problem, we will do our best to help you.

8. Surface treatment: Black oxide, zinc plated, chromium, and according your requirement

9.Packing:Bulk(25kgs/carton) or small package(according to the customers' requirement and the size)

10.Usd fields: Construction industry, furniture fields and other public equipment

We have the following types of equipment:

1.Conventional and CNC Lathes and auto lathes

2.Conventional and CNC Milling Machines

3.High Speed CNC Machining Centres

4.4-axis CNC Machining Centres

5.Precision Wire Cut Machines

6.Surface and Cylindrical Grinders

We also perform various heat treatment processes and metal finishing, chrome, nickel plating and anodizing

Our advantage:

1. Experienced technical staff

2. Product warranty

3. Prompt delivery

4. Quality approval

5. Small order accepted.

6. Competitive price

7. First-class service

Packing method:

Can provide various sizes and packing according to specific requirements

Packing material: PP bag, copy paper, carton, wooden box, pallets

Meet export requirement

According to customer's required

We have many years of experience in the production of OEM, and we have developed products known for quality and service. Look forward to cooperating with you!

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23