Auto Paint Cabin/Auto Painting Cabin/Auto Spray Paint Cabin

Hangzhou Mig Packaging Co., Ltd. / 2022-06-23

- After-sales Service:24 Hours After Service

- Warranty:2 Years

- Type:Coating Production Line

- Certification:CCC, CE

- Substrate:Steel

- Brand:Infitech

=== Base Info ===

- Model NO.:Customized

- Coating:Painting

- Airflow Direction:Fully Undershot-type

- Heating Mode:Direct Firing

- Paint Mist Treatment:Dry-type

- Condition:New

- Control System:Inverter Control System

- Technology:German Technology

- Warranty Time:2 Years

- Touching Screen:Yes

- PLC Controller:Yes

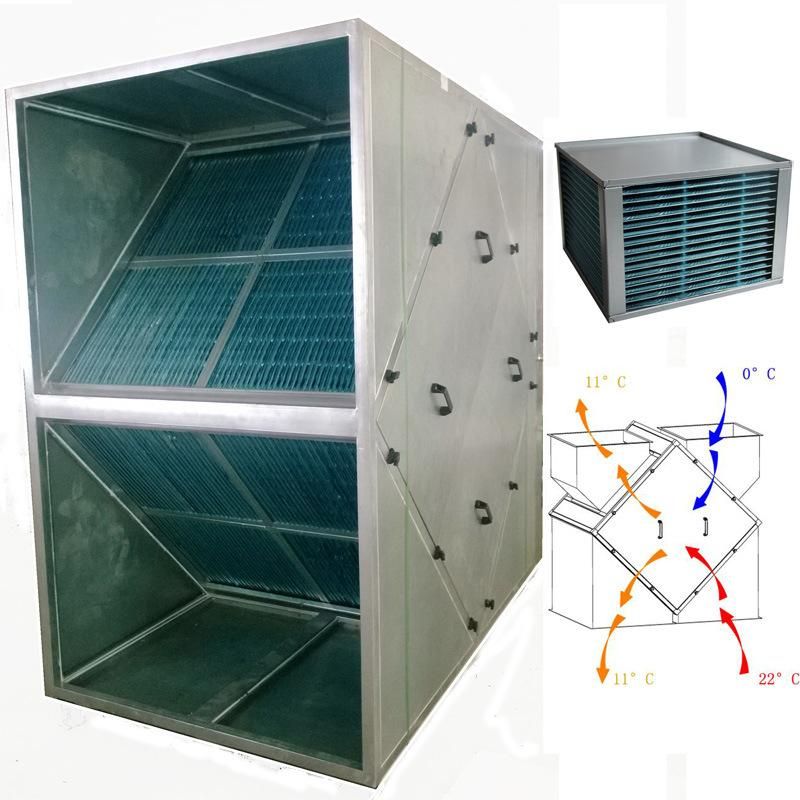

- Energy-Saving System:Cross Plate Heat Exchangers

- Energy-Saving Circuitry:Yes

- Transport Package:Export Professional Packages

- Specification:7000X4000X3000mm(LXWXH)

- Origin:Guangdong, China

- HS Code:8419899090

- Production Capacity:100sets,Year

=== Description ===

Energy-saving Hints

The spray booth itself is generally the largest energy user, since great volumes of pre-heated fresh air will have to be supplied to make up for contaminated exhaust air. These air volumes cannot be reduced at will, since health and safety standards set down by law have to be observed. A paint spray booth must provide adequate air exchange in order to control the concentration of flammable vapors.

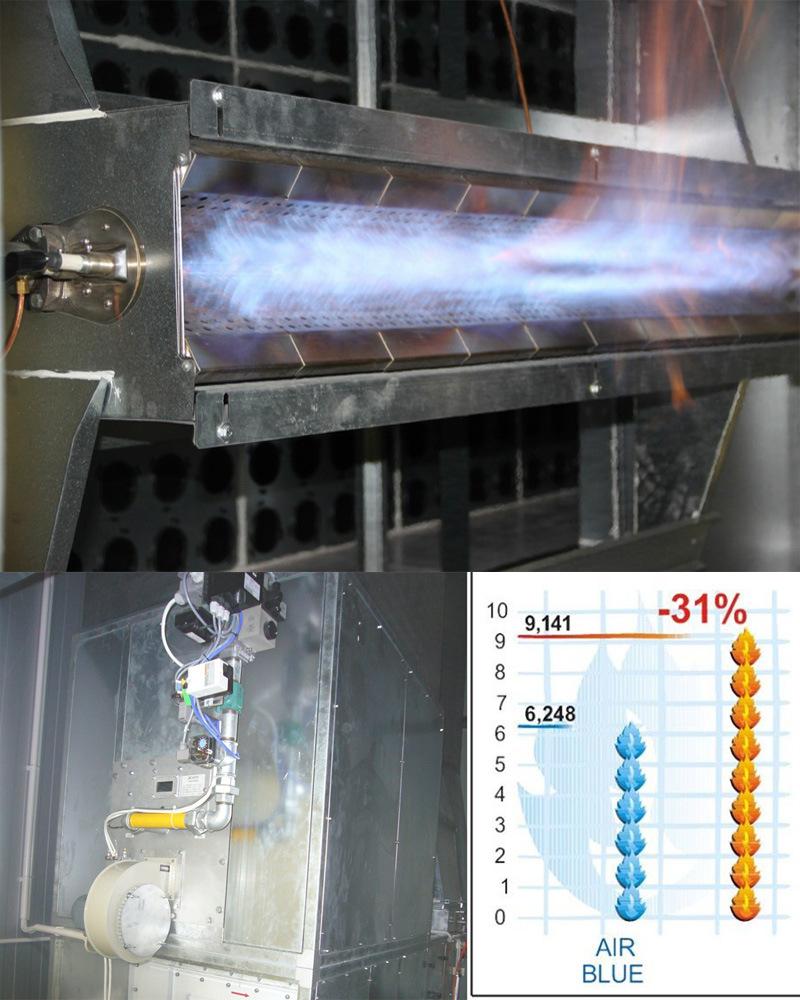

**Direct firing with gas line burners

The advantages are short heat-up times, exact temperature regulation (broad regulation range

of 30:1), low maintenance effort. Quick heating also makes for shorter drying periods.

**Heat recovery

Cross plate heat exchangers are recuperative; moisture is not recovered.The heat passes through thin plates, with recovery levels of up to 38%.The air streams are strictly separated. Whenever solvents are used, the intake and exhaust streams have to be kept absolutely separate. That frequently makes the cross plate heat exchanger the perfect solution. The amortization period is short, often less than two years.

**Energy-saving circuitry

This circuitry offers the capability to reduce energy consumption to a minimum during breaks in operations or while setting up parts for finishing. The mechanism is triggered by hanging up the spray gun. Minimizing exhaust air reduces the energy required for heating the make-up air. Such circuitry is available in two versions. The first is an economical pneumatic damper control for smaller systems. The second is electrical control of the motors via the switchgear cabinet; here a frequency inverter is used to regulate the fresh air supply and exhaust fans.

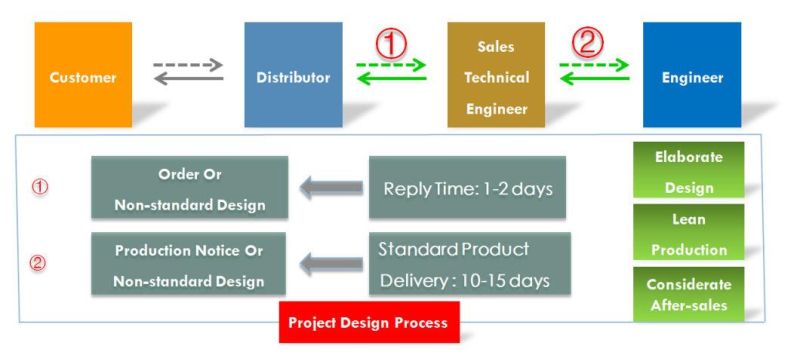

Project Design Process

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23