Woodworking Painting Room and Drying Room with Manual Sliding Door

Hangzhou Mig Packaging Co., Ltd. / 2022-06-23

- Type:Spray Booth

- Certification:CE

- Substrate:Steel

- Coating:Powder Coating

- Airflow Direction:Rear Semi Downdraft

- Heating Mode:Hot Water Heating

=== Base Info ===

- Model NO.:IT-CM-F

- Paint Mist Treatment:Dry-type

- Condition:New

- Airflow:Rear Semi Downdraft

- Extraction Area:6m2

- Grids Carrying Capacity:1,500kg,Wheel

- Brightness:>700lux

- Air Volume:2*28,000m3,H

- Sectional Air Speed:0.46m,S

- Heats:Hot Water Heating, 230kw

- Maximum Working:80 Celsius

- Controls:CE Standard

- Inverter:Schneider

- Stack Light:Yes

- Rated Power:15kw

- Transport Package:Cargo Loaded on Steel Frame Handled by Forklifts

- Specification:3900 X 4000 X 2680mm (L X W X H)

- Trademark:INFITECH

- Origin:Guangzhou, China

- HS Code:8419899090

- Production Capacity:1000 Sets,Year

=== Description ===

Basic Info.

Model NO. IT-CM-F Paint Mist Treatment Dry-type Condition New Airflow Rear Semi Downdraft Extraction Area 6m2 Grids Carrying Capacity 1,500kg/Wheel Brightness >700lux Air Volume 2*28,000m3/H Sectional Air Speed 0.46m/S Heats Hot Water Heating, 230kw Maximum Working 80 Celsius Controls CE Standard Inverter Schneider Stack Light Yes Rated Power 15kw Transport Package Cargo Loaded on Steel Frame Handled by Forklifts Specification 3900 X 4000 X 2680mm (L X W X H) Trademark INFITECH Origin Guangzhou, China HS Code 8419899090 Production Capacity 1000 Sets/YearProduct Description

Woodworking Painting Room and Drying Room with Manual Sliding Door1.FEATURES

The woodworking spray booth comes with 1 spray booth for painting, and 1 drying booth for baking.

The spray booth has rear semi downdraft airflow, and it is equipped with water curtain system to deal with the paint mist, ideal for high painting volume.

The entry and exit door is manual sliding door. There is manual sliding door as divider between the spray booth and drying booth. After painting, the products can be transferred directly from the spray booth to the drying booth for drying.

The solution adopts hot water heating system, with high heat exchanger efficiency, and it is environmental. Certainly, we can change to use traditional diesel or gas heating for the booth.

2.SPECIFICATIONS

| ITEMS | SPECIFICATIONS |

| Model | Customized Woodworking Spray Booth |

| Design standard | BS EN 13355: 2004+A1:2009 BS EN 60204: 2006+A1:2009 |

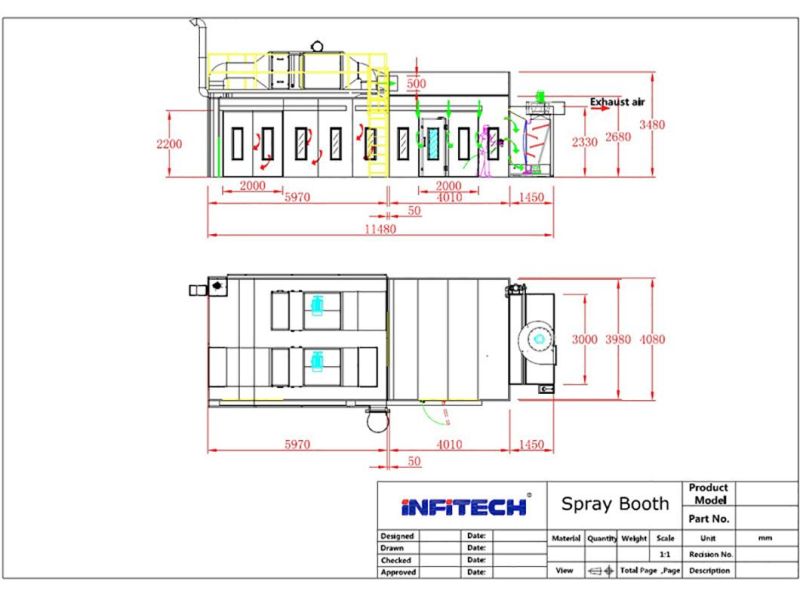

| Internal dimensions | 3900 X 4000 X 2680mm (L X W X H) |

| External dimensions | 4010 X 4080 X 3480mm (L X W X H) |

| Airflow | Rear semi downdraft |

| Paint mist treatment | With water curtain to collect paint mist |

| Extraction area | 6m2 |

| Entrance door | 2000x2200mm (WxH), 1 set, manual sliding door With service door 800x2000mm in 1 door leaf |

| Walls | 50mm rock wool walls, with observation window |

| Ceiling lights (LED) | 4 sets, each 4 X 18W, 288W total |

| Brightness | >700LUX |

| Filters | Pre-filter, ceiling filter(F5 grade), exhaust filter (water curtain) |

| Intake unit | Belt drive fan unit, 10,000m3/h 3KW CE motor |

| Water curtain | 3000x1450x2330mm (LxWxH), made of stainless steel 7.5kw fan unit, 10,000m3/h |

| Sectional air speed | 0.46m/s |

| Heats | Hot water heating, 230KW |

| Controls | Painting, heating painting, lighting, emergency stop, failure indication |

| Rated power | 15KW |

| ITEMS | SPECIFICATIONS |

| Model | Customized Woodworking Drying Booth |

| Design standard | BS EN 13355: 2004+A1:2009 BS EN 60204: 2006+A1:2009 |

| Internal dimensions | 5370 X 4000 X 2600mm (L X W X H) |

| External dimensions | 5970 X 4080 X 2650mm (L X W X H) |

| Airflow | Rear semi downdraft |

| Exhaust plenums | 4000x600x800mm (L X B X H) |

| Extraction area | 3.2m2 |

| Entrance door | 2000x2200mm (WxH), 1 set, manual sliding door |

| Divider door | 1800x2200mm (WxH), 1 set, manual sliding door |

| Walls | 50mm rock wool walls, with observation window |

| Ceiling lights (LED) | 6 sets, each 4 X 18W, 432W total |

| Brightness | >800LUX |

| Filters | Pre-filter, ceiling filter(F5 grade), exhaust filter (fiberglass filter) |

| Circulating fan unit | Belt drive fan unit, 10,000m3/h 3KW CE motor |

| Forced exhaust fan unit | Direct drive fan unit, 3,500m3/h 1.5KW CE motor |

| Heats | Hot water heating, 230KW |

| Controls | Drying, lighting, emergency stop, failure indication |

| Rated power | 6KW |

3.DETAILS

- Design drawing

- Manual sliding entry door

- Water curtain system

When the paint is sprayed on the component, the overspray is sucked rapidly by the exhaust fan. The paint mist is separated from the air and collected by the water-curtain. Moisture is removed from the exhaust air stream by the water eliminator, which prevents moisture from discharging at the exhaust port.

2) Composition

The filtration device consists of water supply system, water-curtain plate, water tank, water eliminator (for warding off water), exhaust fan etc.

The frame, water tank and water-curtain plate are made of stainless steel.

Adopts high pressure centrifugal pump, PVC pipes with good sealing and stable performance

Fan unit for spray booth:

1x3KW belt drive intake fan unit

Fan unit for drying booth:

1x3KW belt drive circulating fan unit & 1x1.5kw forced exhaust fan unit

All fan units are installed at the top of the booth.

| Hot water heating unit | |

| Material | Copper pipe and aluminum sheet |

| Heat exchanger power | 230KW |

| Volume of air to be handled | 10,000m3/h |

| Intake air temperature | -5ºC |

| Outtake air temperature | 63.5ºC |

| Temperature of water at the hot-in port | 80ºC |

| Temperature of water at the hot-out port | 60ºC |

| Water flow | 10t/h |

FAQQ: How do I know if the spray booth can fit my workshop?A: Please send us your workshop layout. We will integrate our design to your workshop so we can check and make necessary changes if necessary.

Q: How do I decide if I take water wash treatment or dry filtration for my spray booth?A: This can depend on many factors, but mainly the following ones.The required production capacityIf the production capacity and painting volume is big, we recommend water treatment.

- The local regulations for water wash treatment and dry filtration.

- The convenience to deal with waste water and solid waste.

- The budget for the project.Q: I need to put the machinery on the floor instead of at the top.

A: That's okay. We can meet your requirements.

Q: What is the warranty?A: 2-year.

Q: I send you the maximum dimensions of the products that I plan to paint. Please propose the appropriate booth dimensions.A: Yes. Meanwhile, if the workshop layout is available, please supply. So we can take it into consideration when working on the solution, and propose the ideal one to you.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23