After Waste Plastic Crushed Washing Recycling Machine, HDPE PP PE Rigid Washed Flakes ...

Zhongshan Tianxin Craft Gift Products Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. pelletizing machine Automation Automatic Computerized Computerized Customized Customized Certification CE, SGS Condition New Name Plastic Flakes Pelletizing Machine Color Custom-Made Motor Siemens Inverters ABB Handle Waste Plastic Flakes Core Part Plastic Film Extruder Centrifuge Dewatering Centrifuge Dewatering City Zhangjiagang Heating Electric Cooling Blower Machine Material 38CrMoAl Cutting Type Watering Temperature Control Temperature Control Contactor Schneid Apply Recycling Machine Transport Package Sea Packing Specification 500kg/h Trademark WEDO Origin China HS Code 847780000 Production Capacity 10 SetsProduct Description

After Waste Plastic Crushed Washing Recycling Machine, HDPE PP PE Rigid Washed Flakes Granulation Melting Plastify Recycle Pelletizing MachineDescription of HDPE PP PE rigid washed flakes melting pelletizing machine:

HDPE plastic pelletizing machine designed with the actual application condition. This HDPE plastic pelletizing machine is specializes for recycling the recycled washed plastic PP HDPE rigid plastic flakes, such as plastic milk bottle flakes, shampoo bottle flakes, medicine bottle flakes, PE drinking bottle flakes, plastic basin flakes, plastic bucket flakes, etc.

After the processing of feeding, heating, melt, cooling, drying, cutting etc., the final products are HDPE plastic pellets/granules that can be to produce plastic chair, plastic profile, plastic bottle, drainage pipes, plastic sheet etc.

Working Flow of HDPE PP PE rigid washed flakes melting pelletizing machine:

Screw feeder → Efficient extruder → Non-stop hydraulic screen filter changer → (second stage extruder → hydraulic screen filter changer → die head →) Water cooling → Strand cutting → Blower → Storage hopper → Electric control panel

The main parts function(canbe customizable)

1. Screw feeder: the first step of the pelletizing recycling machine, plastic scraps such as PP PE rigid washed flakes conveyed into the hopper through screw, the screw connect sensor to detect the material in hopper, once the flakes are full in hopper, the screw will stop; and once empty, the screw feeder will begin working.

2. Extruder: to plasticization and degassing, a specialized single screw extruder applied to melt the pre-compacted material. The plastic scraps will well melted, plasticized in the first stage extruder, and the plastic will be extrude by the second stage extruder. With double-zone vacuum degassing system, volatiles such as low molecular and moisture will be removed efficiency, especially suitable to heavy printed film and material with some water content.

3. Non-stop hydraulic screen filter changer: double stage filtering, fore filtering in the first extruder, and fine filtering in the second extruder, to reduce the frequency of filtering sieves changing. The requirements on the filter technology depend heavily on the quality of the input material as well as the planned use of granules.

4. Water cooling: made of 304 stainless steel, 4 meters length that fill with water, too cooling the melted plastic.

5. Cutting pelletizing: supplied with speed steel and hard alloy steel cutting blades for reliable performance. Compact structure allows less maintenance.

Photos of After Waste Plastic Crushed Washing Recycling Machine, HDPE PP PE Rigid Washed Flakes Granulation Melting Plastify Recycle Pelletizing Machine

over view of HDPE PP PE rigid washed flakes melting pelletizing machine

Main extruder(first stage extruder, mother extruder) of HDPE PP PE rigid washed flakes melting pelletizing machine

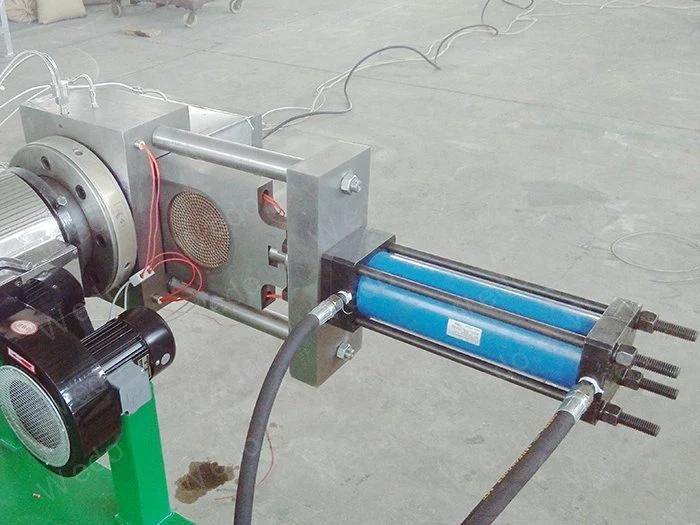

non stop hydraulic screen changer of HDPE PP PE rigid washed flakes melting pelletizing machine

Second stage extruder/ bay extruder of HDPEPP PE rigid washed flakes melting pelletizing machine

Second extruder's screen changer of of HDPEPP PE rigid washed flakes melting pelletizing machine

Final pellets get from Second stage extruder/ bay extruder of HDPEPP PE rigid washed flakes melting pelletizing machine

Parameters of HDPE PP PE rigid washed flakes melting pelletizing machine:

| CAPACITY (kg/h) | POWER CONSUMPTION (kw) | WATER CONSUMPTION | LABOUR | HUMIDITY CONTENT |

| 100-150 | 150 | Keep water cool | 1-2 | <2% |

| 250-300 | 200 | Keep water cool | 1-2 | <2% |

| 350-400 | 280 | Keep water cool | 1-2 | <2% |

| 450-500 | 360 | Keep water cool | 1-2 | <2% |

Advantage of HDPE PP PE rigid washed flakes melting pelletizing machine:

Very low labor request.

Stable running.

Automatic constant temperature control.

CE certification, ISO9001 certification, SGS certification

Configuration based on client requirement and material, and give reasonable suggest.

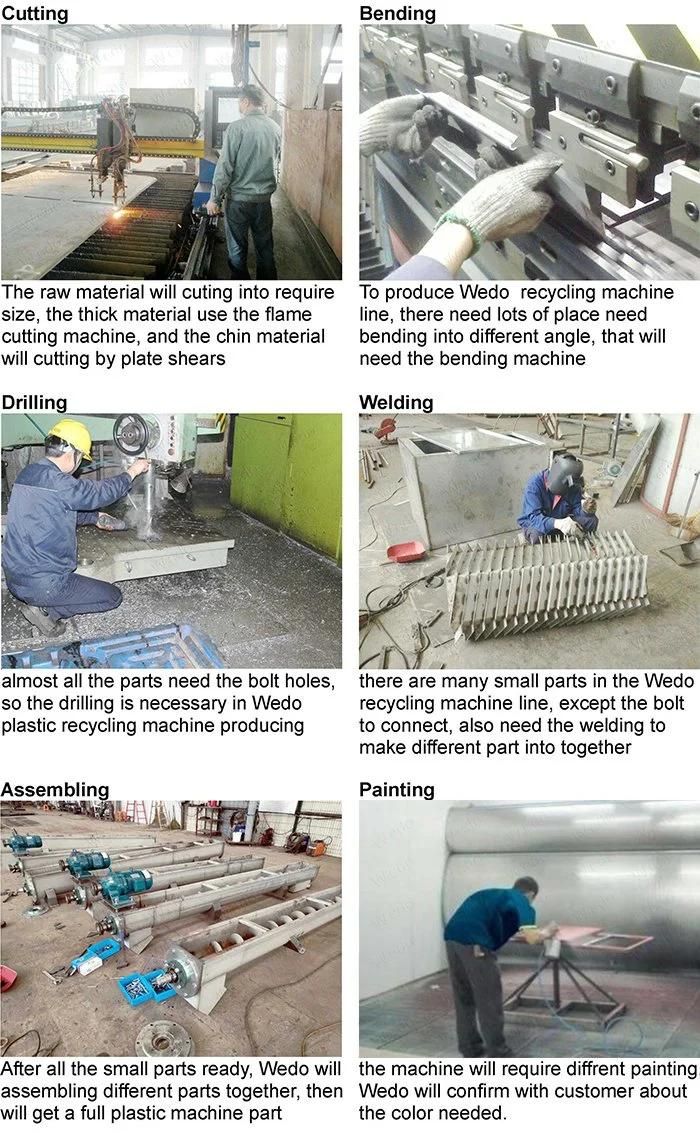

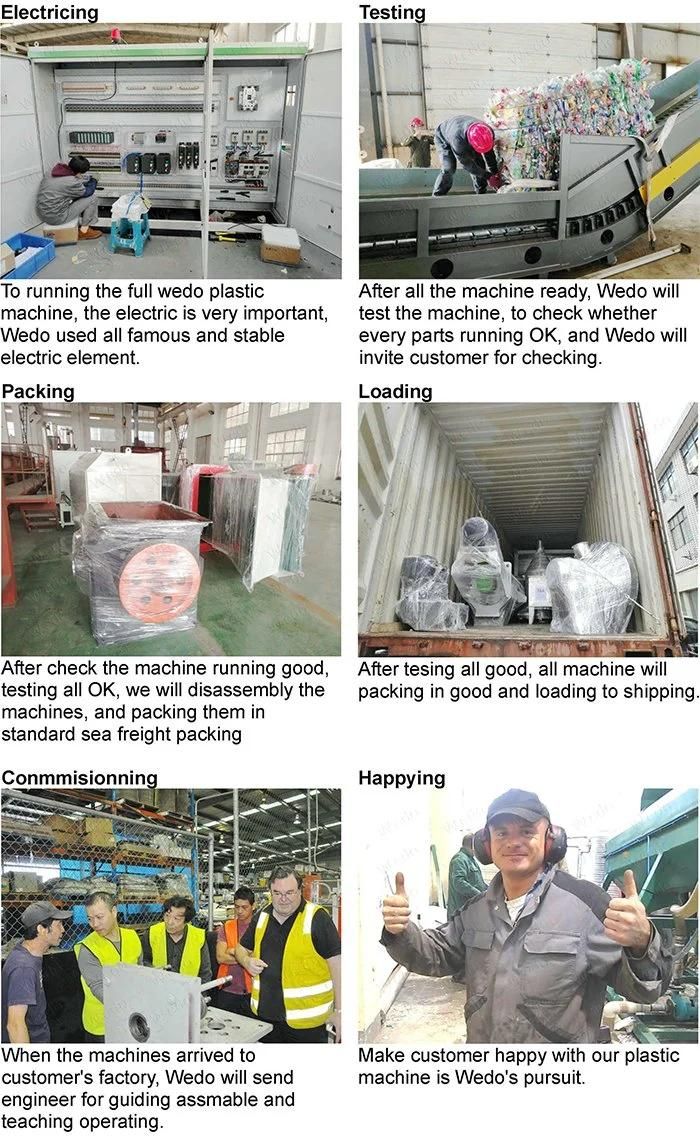

Wedo Produce steps:

Wedo have a fully step for the After Waste Plastic Crushed Washing Recycling Machine, HDPE PP PE Rigid Washed Flakes Granulation Melting Plastify Recycle Pelletizing Machine producing before packing and shipping, this ensure the plastic recycling machine will delivery in good quality, and custerm will get good machine.

Wedo service:

We do best service for you in After Waste Plastic Crushed Washing Recycling Machine, HDPE PP PE Rigid Washed Flakes Granulation Melting Plastify Recycle Pelletizing Machine

Any further about the After Waste Plastic Crushed Washing Recycling Machine, HDPE PP PE Rigid Washed Flakes Granulation Melting Plastify Recycle Pelletizing Machine, please contact us timely we will give your professional fully support.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23