High Speed Plastic Extruder of Powder Coating Machine

Shanghai Guorui Hydraulic Technology Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. TSK40/55/65/75/85 Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Don′t Exhaust Automation Automatic Computerized Computerized Condition Brand New Coating Powder Coated Certification ISO, CE, SGS Transport Package Pallet, Wooden Box Specification TSK 22/30/35/40/55/65/75/85 Trademark Jatchen Origin China HS Code 84779000 Production Capacity 120 Pieces/YearProduct Description

High Speed Twin Screw Extruder of TSK seriesTwin Screw extruder of series TSK is designed with co-rotating twin screws with two independent lubrication system . The raw materials in barrel is perfectly dispersed and homogenizing under melted state by precisely meshing between two screw bushes and mixing blocks. Screw are made of high-grade alloy materials, processed precisely, assures a long working lifetime.

Features:

- High speed of screw shafts resulting high throughput and perfect dispersion.

- Easy to change the configuration of kneading blocks

- shearing and kneading actions are excellent with strong self-cleaning capability.

- Barrel is designed as openable two-half parts with liner inserts for easy cleaning and maintenance.

- High efficient heat-exchanging system of barrel and automatic temperature control system.

- Feeding volume controlled automatically.

- Three models of electric control system for option, and easy to operate:

7.2 PLC control

7.3 Normal control 8. The series of TSK is configured with a high-torque, low-noise, high-efficiency gearbox, lubrication and cooling system are independent for gearbox. 9. Adopt elastic torque protection 10.Excellent self-clean ability 11. Easy to maintenance

12. Safe to operate.

Technical Parameters:

| Model | Thoughput (Kg/h) | Screw Diameter (mm) | Screw Length (L/D) | Main Motor (KW) | Screw Speed (rpm) | Feeder Motor (KW) | Heating/Cooling Zone | Dimension (m*m*m) |

| TSK40H | 150-200 | 40 | 16D | 18.5 | 600 | 0.55 | 3/1 | 2.2*0.6*1.7 |

| TSK55A/55H | 300 | 55 | 16D | 30 | 750/600 | 1.1 | 3/1 | 2.8*0.8*1.8 |

| TSK55B/TSK55BH | 400 | 55 | 16D | 37 | 750/600 | 1.1 | 3/1 | 2.8*0.8*1.8 |

| TSK65A/TSK65AH | 500 | 65 | 16D | 45 | 700/600 | 1.5 | 3/1 | 3.3*0.8*2.3 |

| TSK65B/TSK65BH | 600 | 65 | 16D | 55 | 700/600 | 1.5 | 3/1 | 3.3*0.8*2.3 |

| TSK75/75H | 600/800 | 75 | 16D | 55/75 | 600/800 | 1.5 | 3/1 | 3.6*1.0*2.8 |

| TSK85/85H | 1000/1500 | 85 | 16D | 90/110 | 600/800 | 2.2 | 3/1 | 4.5*1.0*2.8 |

Company Introduction

Yantai Jatchen Powder Coating Processing Equipment Co., Ltd, established in 2011, which specialized in researching and manufacturing of powder coating processing equipment with strong technical team and rich experience. We passed CE certification approval and ATEX explosion resistant test, etc. international standards, "Quality first, Credit first and customer first" is our eternal pursuit. We are committed to provide commissioning and installation support, formulation guidance and 24-hour after-sale service.

Our products have been successfully exported to many countries and regions. like America, Brazil, Canada, India, Turkey, etc. We sincerely welcome you to our company for business visit. we'll try our best to provide the best equipment and solutions to our customers.

Workshop- With highly advanced & precise machining center

- With well-trained & experienced workers

- With strict quality control system

- With EHS & 6S management system

Patent & Qualification:

Why choose us?

"Leading design" + "Excellent performance" + "Best service" = Jatchen's advantages

1. Leading design: the richest experienced R&D team, more than 20 years only keeping eyes on powder coating industry.

2. Excellent performance : the miracle particle distribution result, the biggest savings of materials and labor for your clients.

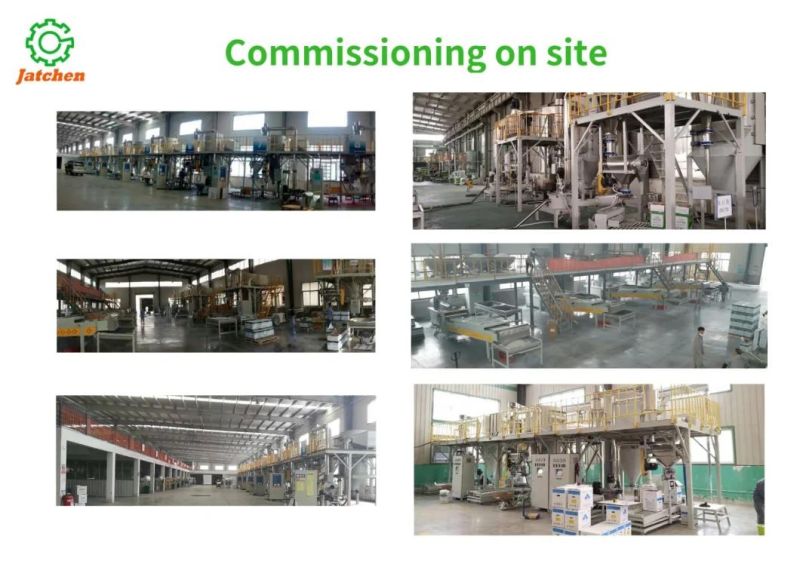

3. Best service: we are committed to 24-hour service, including video technical support, online support, commissioning on site etc.

Successful Cases:

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23