Maize Flour Milling Machine for Super White Maize Flour Super Fine Fmaize Flour

Cangnan Laijiu IMP & EXP Co., Ltd. / 2022-07-05

- After-sales Service:Provide Installation

- Warranty:5 Years

- Type:Flour Mill

- Application:Flour, Maize Flour

- Voltage:380V

- Appearance:Horizontal

=== Base Info ===

- Model NO.:HDFM

- Press Materials:Corn

- Press Series:Second

- Condition:New

- Customized:Customized

- Capacity:10t,24h 20t,24h 50t,24h 150t,24h 300t,24h

- Spare Parts:One Year

- Installation:About 30days

- Pipes:Stainless Steel Pipe in Milling Section

- Packing System:Automatic Packing

- Bags Pack:1kg-50kg

- Oversea Service:Branch Office in Ethiopia Uganda Zambia

- Branch Factory:Ethiopia

- Factory Location:Hebei, China

- Certificate:CIQ, ISO9001 etc.

- Patent Certificate:Degerminator

- Running Machine:Ethiopia, Zambia, Uganda, Egypt, Zimbabwe

- Biggest Capacity:1500t,24h Maize Milling Machine in South Africa

- Noise:<85dB

- Transport Package:40feet Container

- Specification:capacity from small to big

- Trademark:HDF

- Origin:China

- HS Code:84378000

- Production Capacity:50sets,Year

=== Description ===

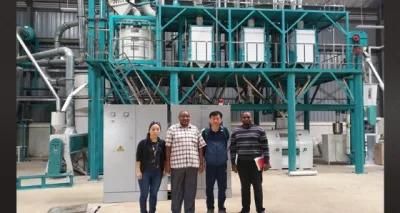

Hongdefa had built a lot Turnkey Projects all over the world.

We're devoted to supply tailor-made Turnkey Project, including project design, manufacture, delivery, installation and testing, worker training, aftersale service.

our 50t/24h maize flour milling machine. It can process 50tons raw maize per 24hours. It is from A to Z, means from start to end. such as maize cleaning machines-dampering-degerminating-roller milling-sifting-packing-control system.

our 50t/24h maize flour milling machine. It can process 50tons raw maize per 24hours. It is from A to Z, means from start to end. such as maize cleaning machines-dampering-degerminating-roller milling-sifting-packing-control system.

The destoner is applied for efficient separation of stones and pebbles, glass, and other high-density matter from the stream of grain. It can remove all the impurity, such as steel, stones, ropes and so on.

The damper can add water to moisten the raw maize. Double layer damper, stainless steel one without rusty and working life is longer than the steel one. Two layers for moisturing much more efficiency.

Our Degerminator with Japan technology, it can remove the maize bran and germ with the most efficiently. you can get the super white maize meal with low fat and without any black point.

In the 50t/24h maize flour milling machine, 4 sets of Roller Mills are working stable and keep the capacity is more than 50tons per 24hours.

2 sets of double bin sifter, we will give you different hole size of mesh screens, to get the different size of final products.

The control system is the Touch Screen smart control system. it is more convenient to control all the machines working. the screen is the best quality in China.

The control system is the Touch Screen smart control system. it is more convenient to control all the machines working. the screen is the best quality in China.The final product of Hongdefa 50t/24h maize flour milling machine.

Our maize flour milling plant can process both white maize and yellow maize, can produce super fine maize flour, refine maize flour, maize meal, maize grits, maize samp, semoule, etc.

---Product Details

---Product DetailsFor the flour mill,we are the most professional.Here show you some HDF projects.

In South Africa,1500t/24h maize milling machine,for Botselo company,is our machine.

In Kenya: Kabasora milling,Gold leaf milling(150t/24h maize mill)

In Zambia:APG milling(3000T Silo and machines),Glance milling(100-130T/D),Chaoma Milling LTD(240T/D maize mill), N.R. Investment. LTD(150-170T/D maize mill)

In Ethiopia: Boni food complex(82t/24h wheat flour mill),Afia food complex(500t/24h wheat flour mill),Tena flour Factory(120t/24h wheat flour mill)

We have office is Uganda,Ethiopia,Zambia.Each Africa country have our milling machine.

6 Important Things to Teach You How to Buy Flour Milling Machines

We know, there are so many suppliers in China for maize milling machines and wheat flour milling machines.

How can we choose the best one?

Which one is best your choose to supporting your milling business?

There are 6 important things to teach you how to buy the best one.

1. Pre-sales Consultation

We can design the processing technology according to your requirements.

Even go to your city for discussing face to face.

2. Equipment Installation

Our professional technicians offer the guidance of installation, commissioning the machines,build up the workshop building and silos,and we can also help to reform the old workshop building as per customers' condition.

3. Reliable Machine Quality

Automatic Roller Mill for saving more cost.

Best quality plan sifter for longer working time.

Steel stainless pipes for food protection and longer working time.

PLC control system with Intelligent control all the machines.

4. Training

Our professional technicians provides training workers of customers' factory,which is helpful to guarantee the normal operation of the equipment and reduce its downtime. In this way, the quality of finished products will be guaranteed.

5. Fixing and Maintenance

Our professional technical team can help solve any problem that occurs in customer's flour production efficiently. We can do regular examinations to the equipment and offer you guidance on the equipment operation if you need. Our staff in Lusaka Office can go to see your site and machines directly and give some advise face to face.

6. Spare Parts Supply

Normally we will send you some wearing parts available for one-year operation of the equipment in our first order. When you are in need of new spare parts in the future, we can send directly from Lusaka/Zambia Office timely where have put a big storage room and delivery door to door.

if you want to buy the high standard with reasonable price , send me your inquiry to us, our design can meet all of your needs.

pls let me know plan, thanks.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23