Industrial Double Shaft Shredder with Replaceable Blade Is Used to Crush Domestic Waste

Wuhan Wanbang Laser Diamond Tools Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

4

7

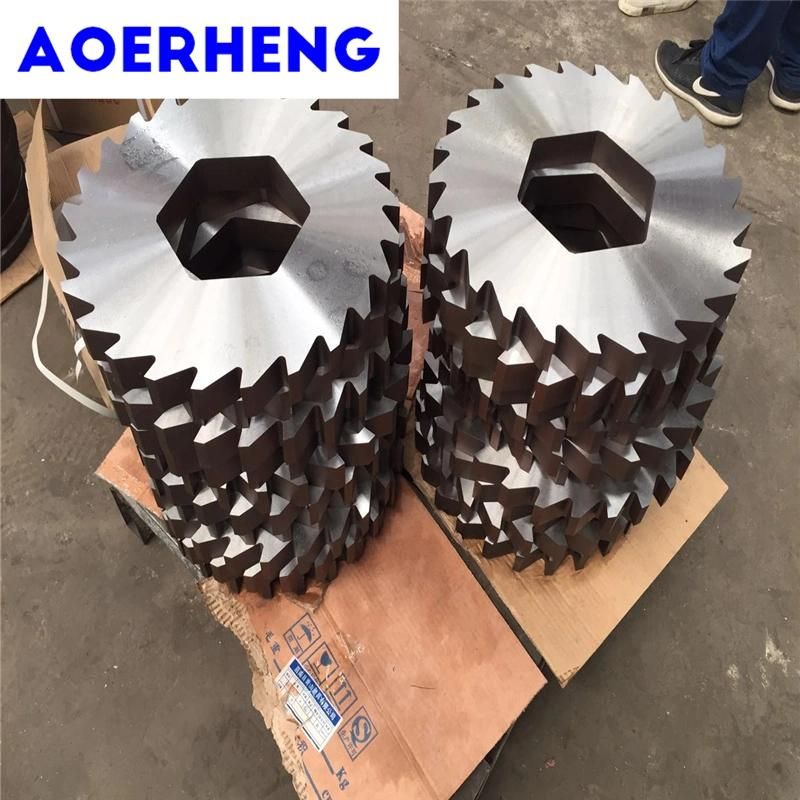

4.Mainly part picture:

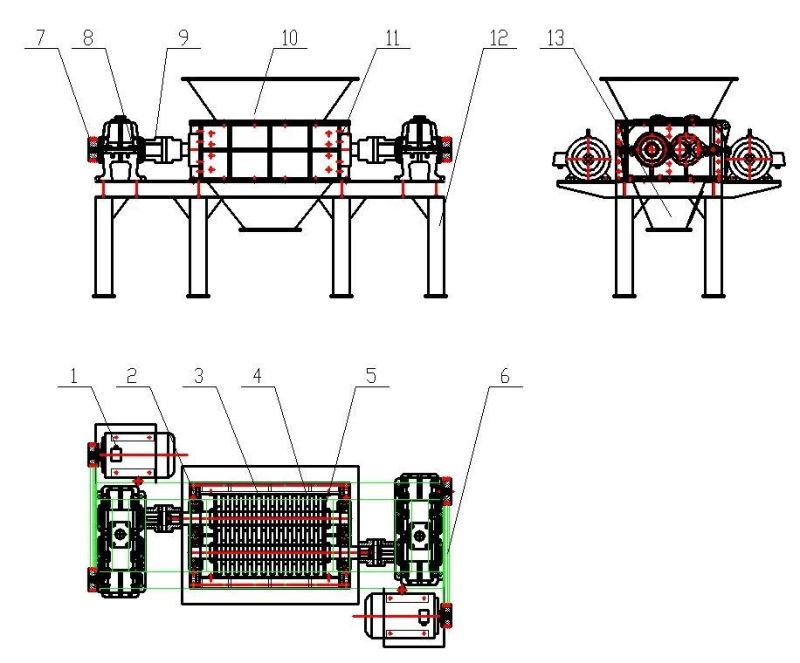

5.Shredder Structure component:

The machine has a very high crushing efficiency. the capacity per hour can choose from 0.3 tons to 50 tons. the particle size of crushed materials can choose from 8mm to 300mm.

According to different materials and handling capacity. zt provides specific blade design and cutter tooth design as well as heat treatment and surface treatment process of cutter head to achieve the desired crushing effect and production efficiency.

7.Our customer:

7.Our customer:

8.Our service:

For most of the machines, the quality is guaranteed for one year since the date of shipment except wearing parts. we supply the

on-line service for all the machines, and also supply the spare parts all the time with cost price. for some complicated machine or

plant. we can send our engineer overseas too

.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23