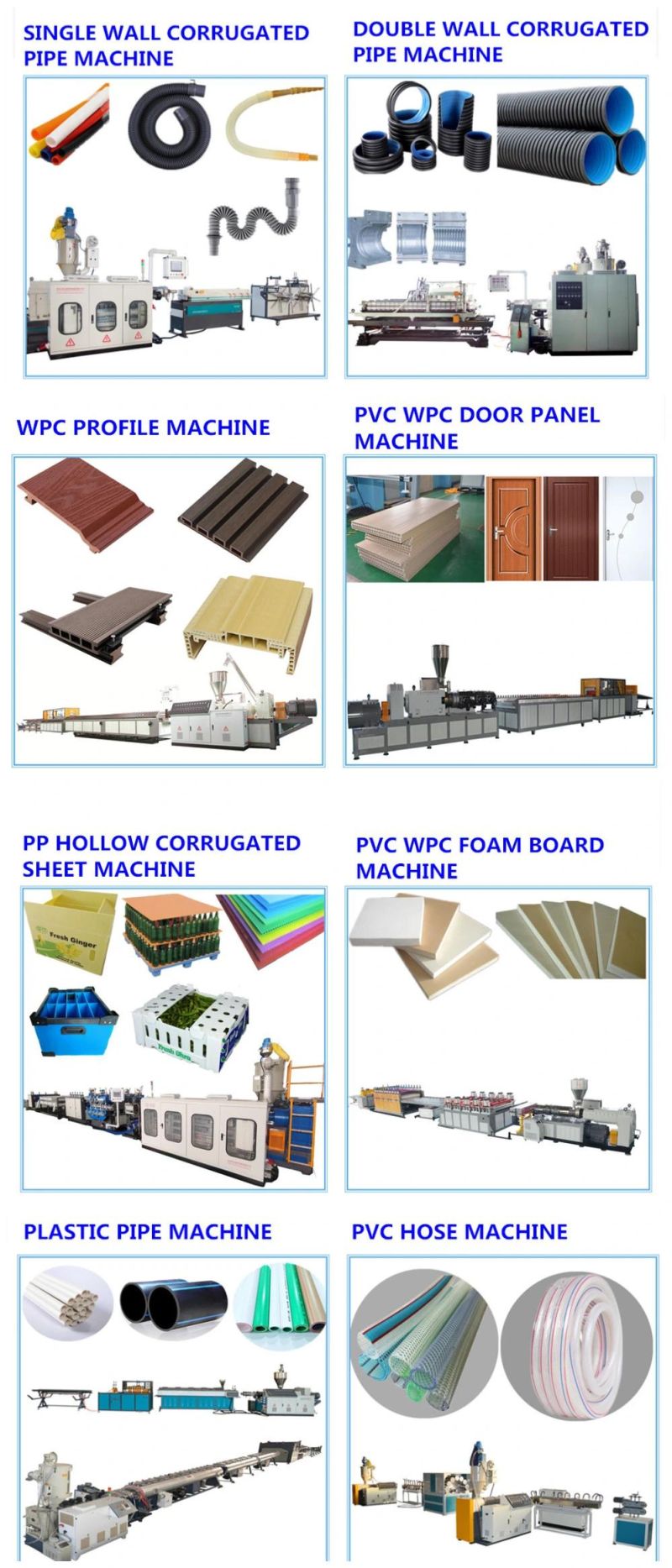

PP PE WPC Wood Plastic Composite Hollow Solid Decking Flooring Production Line

Ningbo Easyget Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

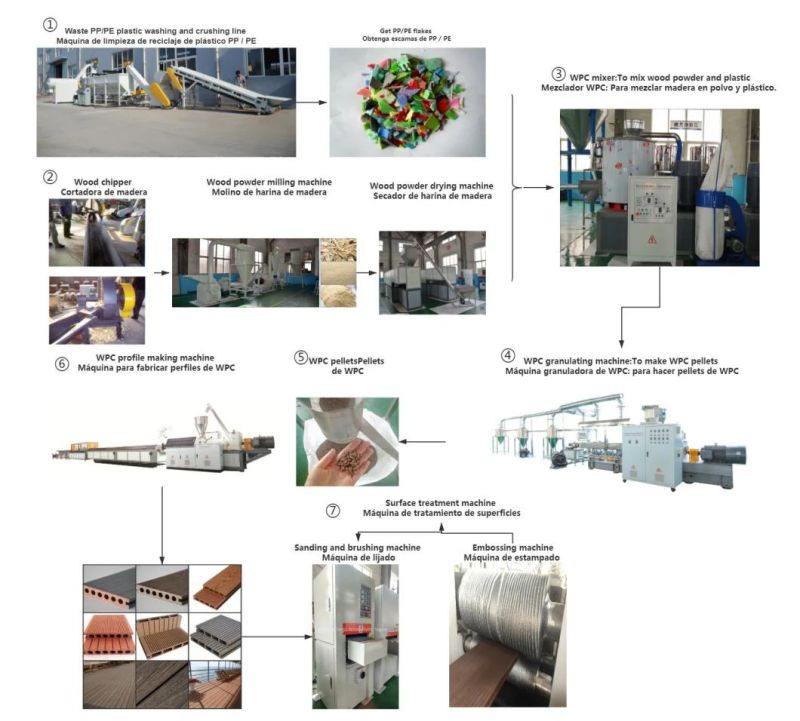

raw material--mixing--granulation--extrusion and molding--surface treatment

The production process of WPC profile as follows:

To recycle waste PP/PE plastic to flakes.

Capacity:500kg/h

(2)PP./PE WPC granulating machine to make WPC pellets

(2)PP./PE WPC granulating machine to make WPC pelletsAfter get ready wood powder and recycled PP/PE plastic, the first step is mixing them with chemicals, then use WPC granulation machine to make WPC granules

SHMS series granulating machine is used for making WPC pellets. The WPC pellets produced by WPC granulating machine can used for making WPC product using WPC machine.The granulating machine consists of parallel double-screw extruder,water cooling system, a granulator and air conveyor cooling system.The feeder and hopper are equipped with mixer to prevent the material blocked up.If customer do not have strict requirements about the appearance of pellets, the granulator can be removed.The pellets extrude by extruder directly, then go for crusher. Can improve the production capacity.

(3)WPC profile making machine to make different WPC profiles.

(3)WPC profile making machine to make different WPC profiles. Material: recycled 30% PP/PE+70% wood powder+chemical additives.

Product: WPC decking, WPC wall cladding, WPC fence, WPC pergola..

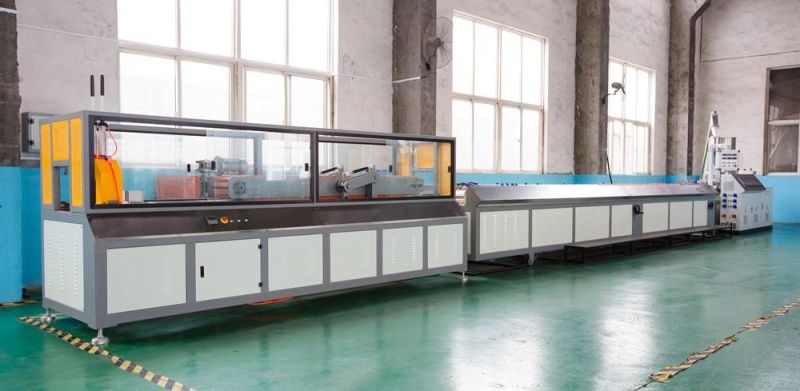

The WPC profile extrusion line can make WPC granules into WPC products by equipping required mold, we can equip co-extrusion system and online 3D embossing device for making WPC products in high quality with wooden grain, the line also equipped with online cutting device.

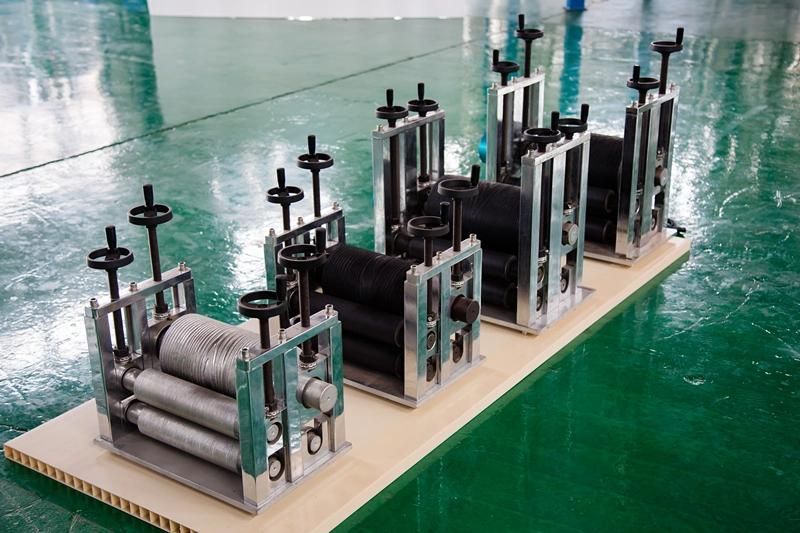

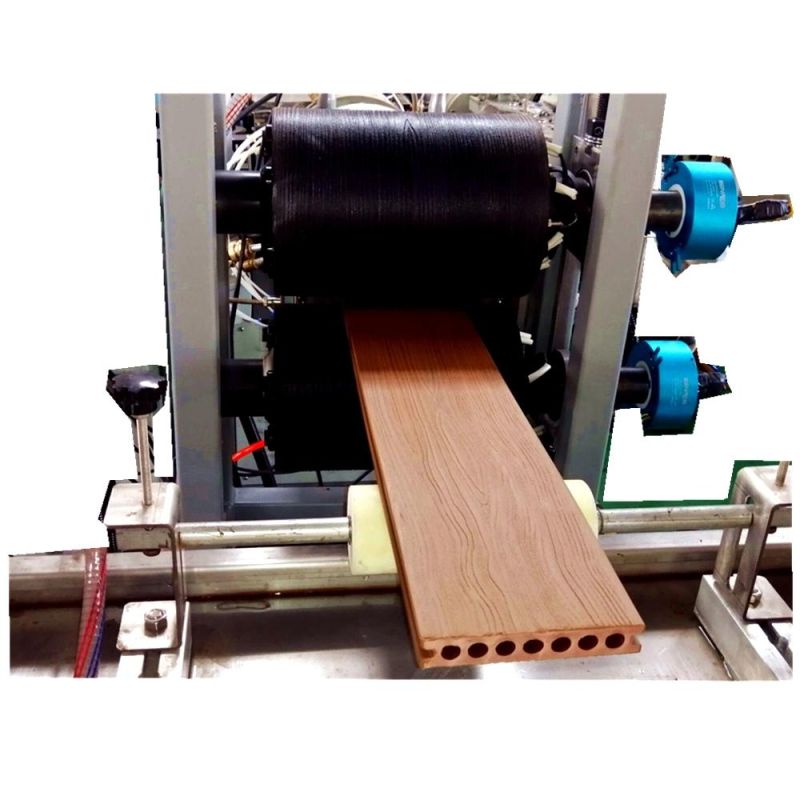

(4) WPC product wood surface making machineEmbossing machine, sanding machine, brushing machine, online embossing machine. these machines is for making WPC products with better wooden feeling design.

(4) WPC product wood surface making machineEmbossing machine, sanding machine, brushing machine, online embossing machine. these machines is for making WPC products with better wooden feeling design.WPC embossing machine:

We have high quality embossing machine to make 3D pattern on the WPC profile.

WPC sanding machine

This machine is used for fixing the size of single extrusion WPC product and doing surface treatment

WPC brushing machine

This machine is used for brushing the WPC product. To do the different surface on WPC product by changing the brushing roller and sanding roller

WPC brushing and sanding machine

This machine is used for doing surface treatment of different WPC product. This machine has the function of sanding machine and brushing machine.

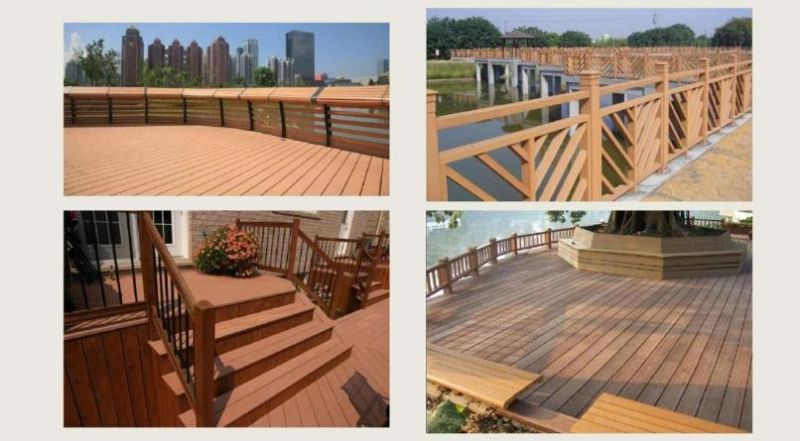

PE WPC Products Application

PE WPC Products ApplicationThe PE WPC profile extrusion line is suitable for producing the hollow/solid PE WPC profiles. This profile has the advantage of fireproof, waterproof, moisture proof, moth proof, mildew proof and environment friendly. It is mainly used for extruding outdoor decorative WPC profiles, such as gardening landscapes, outdoor landscapes, pallets etc.

This extrusion line is for producing co-extrusion PP/PE WPC decking. The decking surface can be made into wood grain by co-extruder. Further more, the machine can be equipped with on-line embossing device the surface can be made into 3D wood grain. The WPC decking has a series of advantage including water-proof, insect prevention, ageing resistant, easy installation, environment friendly and good weathering resistance.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23