for Vacuum Forming ABS HIPS PMMA PC Sheets Boards Plates Extrusion Line Extruder Machine

Xinzheng Lifa Abrasives & Abrasives Co. Ltd / 2022-07-04

=== Base Info ===

=== Description ===

PART 5 COMPANY INFORMATION AND MAIN PRODUCTS:

PART 6 OUR RELIABLE SUPPLIERS:

PART 7 COMPANY CERTIFICATIONS:

PART8 MACHINE PACKING AND DELIVERY

All the machine parts will be packed in wooden cases or pellets with stretching films on machine body.

PART 9 COMPANY OVERSEA SHOWS AND CONTACT DETAILS:

PART 10 OTHER KINDS OF PLASTIC SHEETS/PLATES EXTRUSION LINE RECOMMENDATION :

1. PET sheet extrusion machine:

Processing material: PET virgin pellets(APET or PETG) plus flakes; Or 100% flakes

Thicknes range: 0.2-1.5mm

Net sheet width: 650mm-1500mm(or as per cusotmer's requirement)

Layer structure: Signle layer or multi-layer

Capacity: 150-650kg/h

Application: Thermoforming(cup, bowel, etc. ), stationery, printing sheet, packaging, etc.

2. PP/PS sheet extrusion machine:

Processing material: PP/PS virgin pellets plus recycle material;

Thickness range: 0.15-2mm

Net sheet width: 650mm-720mm-1000mm-1300mm-1500mm(or as per customer's requirement)

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-1000kg/h

Application: Thermoforming(cup, bowel, etc. ), stationery, printing sheet, packaging, etc.

3. ABS/HIPS sheet extrusion machine:

Processong material: ABS/HIPS virgin pellets plus recycle material

Thickness range: 1-6mm

Net Sheet width: 1200mm-1600mm-2100mm(or as per customer's requirement)

Layer Structure: Single layer or multi-layer

Capacity: 300-800kg/h

Application: Vacuum forming, thermoforming, refrigerator inner layer, suitcase, etc.

4. ABS/PMMA sheet extrusion machine:

Processing material: ABS/PMMA virgin pellets plus recycle material

Thickness range: 1-8mm

Net sheet width: 1200mm-1600mm-2100mm(or as per customer's requirement)

Layer structure: Single layer or multi-layer

Capacity:300-800kg/h

Application: Vacuum forming, bathtube, etc.

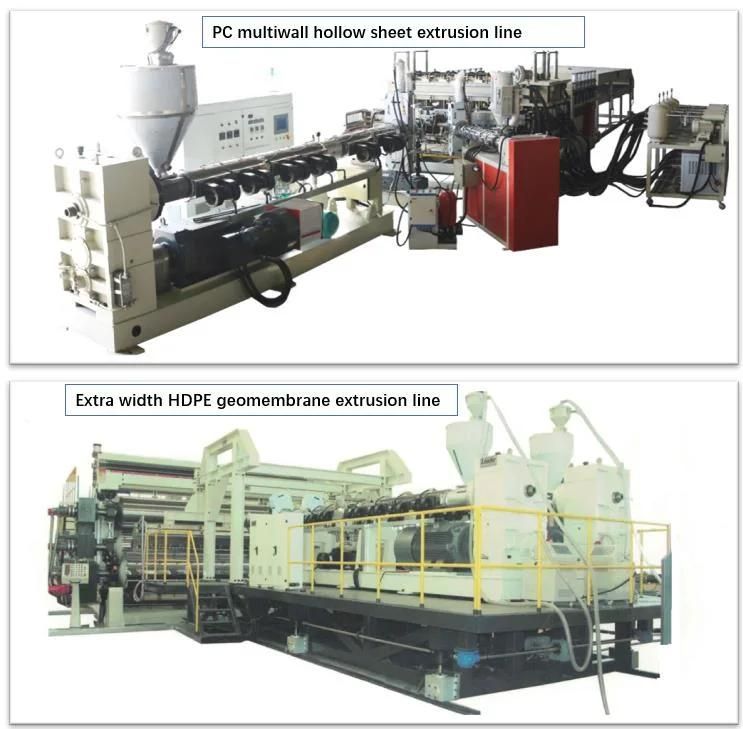

5. PE sheet extrusion machine:

Processing material: HDPE/LDPE/LLDPE virgin pellets plus recycle material

Thickness range: 1-2.5mm, 3-35mm

Net sheet width: 1200mm-1600mm-1800mm-2500mm-3000mm-40000mm-6000mm-8000mm

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-1200kg/h

Application: Packaging, construction, water-proof, water-drainage, Geomembrane film, etc.

6. PC/GPPS/PMMA sheet extrusion machine:

Processing material: PC/GPPS/PMMA virgin pellets plus recycle material

Thickness range: 1-12mm

Net sheet witdh: 600mm-1220mm-2100mm(or as per customer's requirement)

Layer Structure: Single layer or multi-layer

Capacity: 200-600kg/h

Application: Ads., decoration, roofing, etc.

7. PC/PP/PE hollow profile sheet/ sunshine roofing panel machine:

Processing material: PC/PP/PE virgin material plus recycle material

Thickness range: 2mm-4mm-6mm-8mm-10mm-12mm

Net sheet width: 1220mm-2100mm

Layer structure: Single layer or multi-layer

Capacity:200-600kg/h

Application: Ads. Decoration, roofing, packaging, printing, etc.

8. PVC sheet/edge banding sheet/marble sheet machine:

Processing material: PVC power plus other additive

Thickness range: 0.15-1mm; 1-3mm; 3-12mm

Net sheet width: 650mm-2000mm-3000mm( or as per customer's requirements)

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-500kg/h

Application: Thermoforming, stationery, printing, payment card, SIM card, construction, etc.

9. PVC free foam/celuka foam board extrusion line

board width: 1220mm, thickness: 1-10mm, 3-25mm

board application: decoration board, advertising boards, exhibition boards

extruder model: SJ-80/156 conical twin screw extruder

max capacity: 350kg/h

certifications: CE, ISO9001-2008

10. EVA car interior decoration sheet extrusion line

Processing material: EVA and other additives

Thickness range: 1-8mm

Width range: 1000-1800mm

Layer strcuture: single layer

Capacity: 700-800kg/h

Application: automotive sealing strips, sound insulation cushion, sound absorption sheets,

automobile tail box, fenders, car interior and exterior decoration parts etc.

11. PVC+PMMA Glazed roofing tiles/corrugated sheet extrusion machine

Processing material: PVC, PMMA and other additives

Thickness range: 1-8mm

Width range: 720mm, 880mm, 1040mm

Layer structure: A/B, A/B/A, A/B/C

Capacity: 400kg/h

Application: garden-style factory, tourist scenic spots, pavillions, hotels, family building etc.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23