Plastic Pellet Parallel Twin Screw Extruder Making Machine

Danyang Huate Tools Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

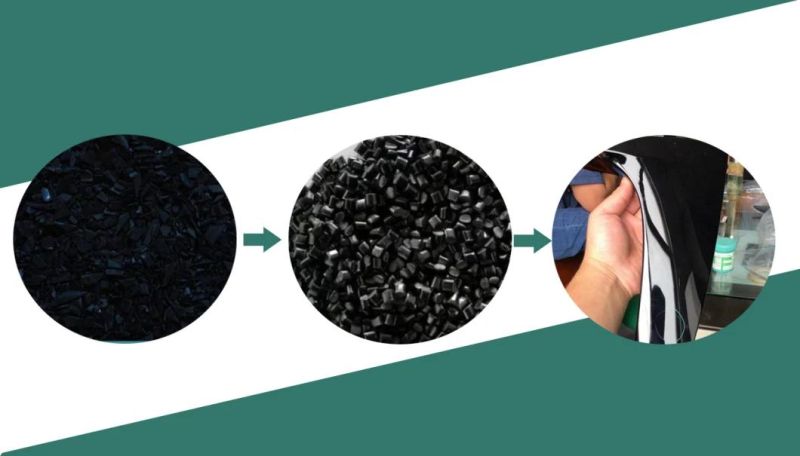

Functional machine pellets

Powder paint

Service process

SERVICE

1. Pre-sales service

Detailed introduction of product characteristics, the scope of application.

Planning economical and practical equipment configuration scheme for you.

Provide information about the performance of the relevant equipment that you are interested in.

2.Service in sale

Planned and designed the layout and configuration of the equipment in the existing workshop, and put forward the conditions of public works.

I will keep you informed of the progress of the project.

Discuss with you the process conditions, screw combination, cylinder arrangement and so on required by your department.

3 After-sales service

Provide on-site installation instruction, commissioning and personnel training.

Establish a detailed user profile.

Sufficient spare parts are available to relieve your worries about the maintenance of the original equipment due to the investment of new models.Provide equipment adjustment service for new product development in time.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23