Full-Automatic Wafer Production Machine (BBC300)

Hebei Hightop Metal Mesh Co., Ltd. / 2022-07-05

- Certification:CE, ISO9001

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

- Application:Biscuit

- Customized:Customized

=== Base Info ===

- Model NO.:BBC300

- Capacity:120kw

- Daily Output:2.2-2.5t

- Transport Package:Wooden Case

- Specification:CE

- Trademark:SHENWEI

- Origin:Shanghai China

- HS Code:84382000

- Production Capacity:20sets,Year

=== Description ===

Basic Info.

Model NO. BBC300 Capacity 120kw Daily Output 2.2-2.5t Transport Package Wooden Case Specification CE Trademark SHENWEI Origin Shanghai China HS Code 84382000 Production Capacity 20sets/YearProduct Description

descriptions:general description

Adopting hearingmedium conduction technology with heating oil as medium,the plant is a new generation product developed exclusively in China based on the advanced structure of existing plants from domestic market and abroad.If offers an ideal solution for lower power consumption and overall production cost,and keeping the same surface color for all biscuits.The plant mainly consists of mixing system,automoatic feeding system, tunneltype oven, sheet feeding and cooling device,coating machine,cutter and organic heating medium boiler, ect.With compact structure and unique reliability, the plant is one of the most preferred equipments in foodstuff industry.

Main technical and requirements:<o:p>

<o:p>

1.The whole shell of the production adopts 304 stainless steel in accordance with the health and safety standard.<o:p>

2.The electricity and transmission components are all used Siemens,Mitsubishi,Touch screen to control and adopts the international Brand Germany SEW,SKF to make the whole line steadily.<o:p>

3.In according to client's requirements,we can make a wide range of size and shape cream(chocolate) filled wafer biscuit full automatically.<o:p>

finished products:

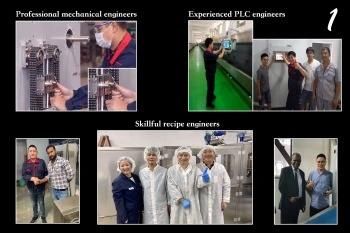

After-sale service for abroad customers. 1. Free training of macine installion, operation and maintenance will be provided by our engineer.2. Some spare parts will be sent with the machine for free. It is available to buy the parts from us forever at low price.3. We will surpport customers after-service forever by call, email and video etc.4. If necessary, our engineer is available to go to customer's factory for machine installion and adjustment

Why choose us? ·Nearly 20 years experiences in food processing machinery production, established in 1982. ·We are manufacturer and wholesale of dough kneading machine ·We adopt environment-friendly materials and technology ·We mainly sell stock in bulk. OEM orders are welcome · We can accept the mix order

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23