Wine Drink Production Line/Aseptic Beer Filling

Jiangyin Yiran International Trading Co., Ltd. / 2022-07-05

- Condition:New

- Customized:Customized

- Voltage:220V

- Composition:Filling Machine

- Processing Material:Natural Ingredients

- Process:Frozen and Chilled

=== Base Info ===

- Model NO.:GYV-8000

- Raw Material:Fruit

- Name:Wine Production Line

- Capacity:2000b,H

- Color:Silver

- Transport Package:Wine Production Line Wooden Boxes

- Specification:3*2*12m

- Trademark:genyond

- Origin:Shanghai

- HS Code:8438400000

- Production Capacity:5000

=== Description ===

Basic Info.

Model NO. GYV-8000 Raw Material Fruit Name Wine Production Line Capacity 2000b/H Color Silver Transport Package Wine Production Line Wooden Boxes Specification 3*2*12m Trademark genyond Origin Shanghai HS Code 8438400000 Production Capacity 5000Product Description

Efficient and cost-effective.

A Combi offers higher performance through fewer machines, improving production efficiency by up to 4% and reducing the total cost of operation by up to 12%.--- Compact and ergonomic, with only one operator.

--- Optimized line layout with no empty bottle storage, handling, accumulation or rinsing.

--- Significant light-weighting opportunities through bottleneck handling and elimination of intermediary conveying.

Enhanced hygiene.

By combining blowing, filling and capping within a single enclosure, the Combi optimizes hygiene and food safety.--- Contact-free filling, with all parts in contact with a beverage made from stainless steel AISI 316L.

--- Automatic dummy bottles available, with insertion and removal available for automated CIP.

--- Optional reduced filler enclosure strengthens food safety and reduces the usage of chemical agents and water during external cleaning.

Sustainable production.

The Huihe Combi offers great savings potential with regard to raw materials, electricity, air consumption, and chemical usage.--- 45% reduction in electricity consumption during blowing with infrared ceramic lamps.

--- Servomotors improve electrical efficiency.

--- Up to 35 % reduction in compressed air consumption with the option.

--- Smaller filler enclosure reduces footprint and chemical usage during external cleaning.

--- Integrated Cleaning System optimizes space, resulting in quicker cleaning, less CIP agent usage, and reduced resource consumption.

This machine need air compressor, 0.8 m3/min 10Kg is enough

This machine can be connected with:

- Water treatment system

- Glass bottle depalletizer

- Glass bottle washer, filler-seamer monoblock

- Glass bottle cooling tunnel

- Glass bottle blow dryer

- Liquid level inspector

- Glass bottle labeling machine

- Glass bottle code printer

- Glass bottle packaging system (shrink-wrapper or carton packaging machine)

- Palletizing system

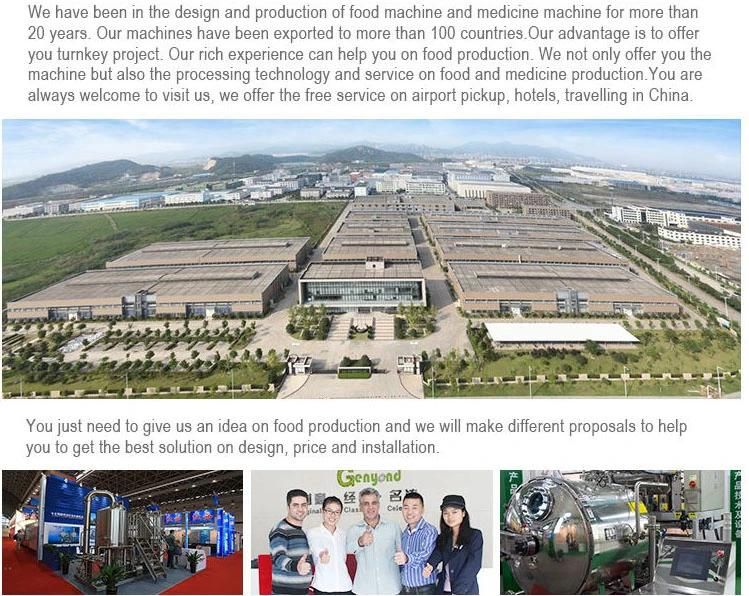

Shanghai Gengyond machinery Technology Co.,Ltd.

Shanghai Gengyond machinery Technology Co.,Ltd.ADD: 709,No.1328,Hengnan, Road, Minhang District,

Tony Wong

Mob : 0086 18116095133

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23