Fresh Milk Pasteurizer Plate Juice Uht Sterilizer

Ningbo Hopson Chemical Industry Co., Ltd. / 2022-07-05

- Customized:Customized

- Certification:CE, ISO

- Scale:Medium

- Automation:Automatic

- Principle:High Temperature

- Structure:Plate

=== Base Info ===

- Model NO.:PM-UHT

- Operation:Continuous

- Energy:Heat Sterilization

- Property:Physical Sterilization

- Type:Steam

- Transport Package:Wooden Case

- Specification:2.5m*2.0m*2.2m

- Trademark:PROMAN

- Origin:China, Jiangsu

- HS Code:8422301090

- Production Capacity:100sets,Year

=== Description ===

Basic Info.

Model NO. PM-UHT Operation Continuous Energy Heat Sterilization Property Physical Sterilization Type Steam Transport Package Wooden Case Specification 2.5m*2.0m*2.2m Trademark PROMAN Origin China, Jiangsu HS Code 8422301090 Production Capacity 100sets/YearProduct Description

fresh milk pasteurizer plate juice UHT sterilizer This equipment adopts new high-efficiency BR and BP plate heat exchangers widely used in modern engineering field. Through the non-contact heat exchange between materials and superheated steam (or superheated water), the fluid materials can reach the required sterilization temperature in a short time. With good heat transfer effect and is good and easy to clean. It is an ideal sterilization equipment for fluid drinks such as milk, juice and vegetable juice.

This equipment adopts new high-efficiency BR and BP plate heat exchangers widely used in modern engineering field. Through the non-contact heat exchange between materials and superheated steam (or superheated water), the fluid materials can reach the required sterilization temperature in a short time. With good heat transfer effect and is good and easy to clean. It is an ideal sterilization equipment for fluid drinks such as milk, juice and vegetable juice.Process

Material--→balance tank45~55°C→heating95°C→overheating120°C (120 insulation 15s)→cooling95°C→55~65°C (outlet temperature can be adjusted according to process requirements) →Filling (or reflux)

This machine can be used in the aseptic heat treatment system of liquid beverage foods. It uses high-precision product/water temperature difference control. The product is input into the heat exchanger from the balance tank, and the heat is exchanged with the sterilized hot material. The temperature of the material rises to a predetermined value, and then indirectly heated to 120 ° C by steam heated water, and the material is maintained at a set temperature for a period of time in the temperature maintaining tube for ultra-high temperature sterilization. The material is heat exchanged and finally cooled to a predetermined outlet temperature in the cooling section. The whole process is carried out in a closed state to achieve the purpose of ensuring the biological stability of the material. According to the different process requirements of materials heating, heat preservation and sterilization cooling, the user can design a specific combination system to meet various process requirements.

The unit is mainly composed of material balance and conveying system, plate heat system, material pipeline system, hot water heating system, steam pipeline system, material automatic reflux system, temperature automatic control and electrical control system.

Technical parameters

| Sterilization temperature | 120ºC |

| Sterilization time | 15seconds (or according to customer's requirement) |

| Material outlet temperature | 55-65ºC (or according to customer's requirement) |

| Steam pressure | ≥0.7MPa |

| Steam consumption | 120~150kg/h |

| Compressed air | ≥0.7Mpa |

| Cooling water pressure | 0.3Mpa |

| Cooling water inlet temperature | ≤15ºC |

| Gross weight | 1680kg |

| Overall size | 2500×2000×2200mm |

Features:

1. The material and the heating medium are heated by non-contact heat exchange in their respective sealing systems to ensure the hygiene and safety of the materials;

2. Short sterilization time ensures that the nutrients of the materials are not destroyed;

3. The whole machine adopts food grade stainless steel materials to ensure that can meet the national requirements for safety and health indicators of beverage and food;

4. Good heat transfer effect, high heat recycling rate and low energy consumption;

5. The main control components, valve parts and auxiliary parts are all international famous brands, which have a long service life;

6. Adopt PLC control, so can automatically control the heating temperature, hot water temperature and steam flow adjustment of each section of the material, and has an automatic material reflux system to ensure that the material reaches 100% sterilization effect;

7. Simple structure, easy to clean, easy to operate and low maintenance cost.

Our service

Our serviceCustomized service

We can design the machines according your requirements(material,power,filling type,the kinds of the bottles,and so on),at the same time we will give you our professional suggestion,as you know,we have been in this industry for many years.

After-sales service

1.We will delivery the machine and provide the bill of load on time to make sure you can get the machine quickly

2.When you finish the Preparation conditions,our fast and professional aftersales service engineer team will go to your factory to install the machine,give you the operating manual,and train your employee until they can operate the machine well.

3.We often ask feedback and offer help to our customer whose machine have been used in their factory for some time.

4.We provide one year warranty

5.Well-trained & experienced staff are to answer all your inquiries in English and Chinese

6.24 hours for engineer response (all services part 5days in customer hand by Intl' courier).

7.12 Months guarantee and life-long technical support.

8.Your business relationship with us will be confidential to any third party.

9.Good after-sale service offered, please get back to us if you got any questions.

Quality Control

We have separate quality control department, which make sure the raw materials are qualified, also ensure the machine running smoothly.

If you want to know more information about the product,Send inquiry to us, we will solve any of your problems and send you running video for reference.

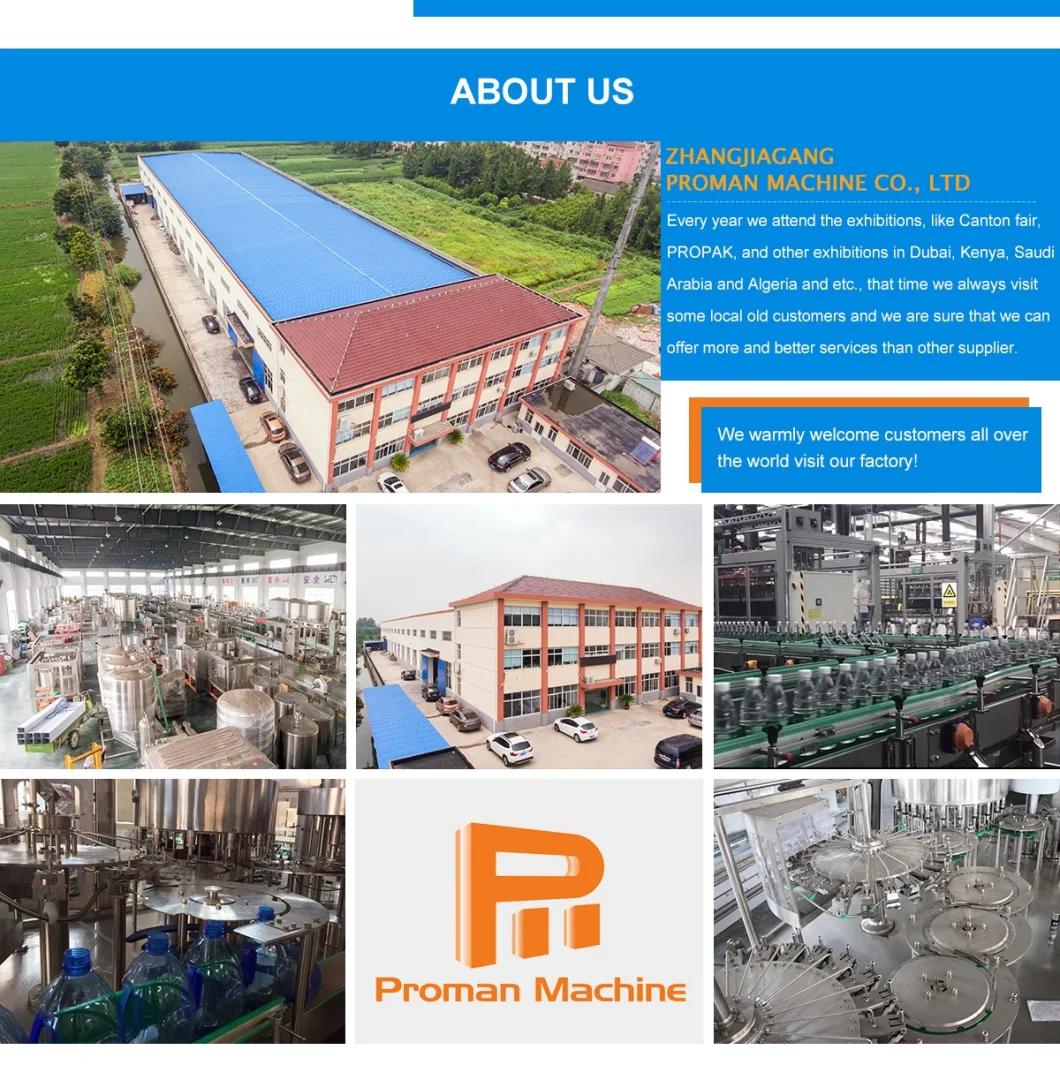

Zhangjiagang Proman Machine Co. Ltd,is a production manufacturer and exporter specialized in water treatment plants,beverage filling machine, packing machine, bottle blowing machine, injection moulding machine and spare parts of filling line.

Zhangjiagang Proman Machine Co. Ltd,is a production manufacturer and exporter specialized in water treatment plants,beverage filling machine, packing machine, bottle blowing machine, injection moulding machine and spare parts of filling line.Our factory was established in the year of 1998, with the long history of accumulated experience in filling machine industry in south Jiangsu. There are many development engineers of filling machine in our company. We devote ourselves to the development, research and production of liquid food and beverage packing and filling industry.

Besides, we have our own designs for the bottles.

Proman Machine cooperated with many customers in recent years, we win the trust of customers from our high-quality products. And we are looking forward to the future cooperation with you if our products can impress you deeply!

FAQ

FAQ1.Where is your factory? Our Factory is located in Zhangjiagang City, 2 hours drive from Shanghai and 1 hour drive from Wuxi(airplane & high-speed rail). If you arrive at Shanghai or Wuxi, we can pick you up to visit our factory.

2.Do you have any technical supports with your Beverage Filling Machines?

Yes, We have a professional team of engineers who owned many installation, debug and training experiences abroad, are available to service machinery overseas.

3.What's your guarantee or the warranty of the quality if we buy your machines? We offer high quality machines with 1 year warranty and supply life-long technical support.

You're always welcome to visit our company. If you have any interest on our products. Please do not hesitate to contact us.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23