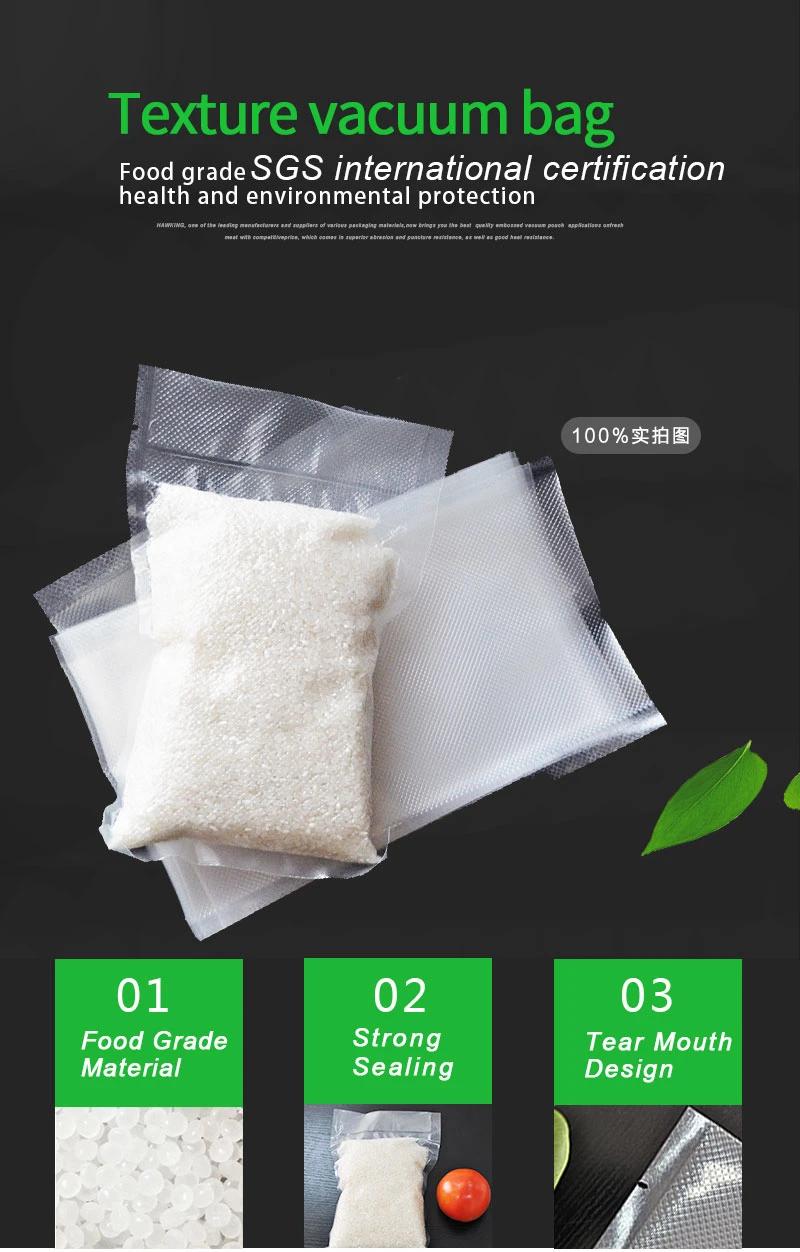

Plastic Bag Embossed Vacuum Bag / Pouch for Food Packaging

Hubei Hawking Packaging Material Co., Ltd. / 2022-06-09

- Making Process:Plastic Packaging Bags

- Shape:Seal Bag

- Material:PA,PE

- Feature:Moisture Proof, Recyclable, Bio-Degradable

- Application:Food, Chemical

- Raw Materials:Polypropylene Plastic Bag

=== Base Info ===

- Specification:7 Layer, 9Layer Co-extruded

- Transport Package:Pallet or Carton or Customized

- Certification:SGS, ISO9001, ISO14001, QS

- Export Port:Shanghai Port

- Size:Customized

- Thickness:30-200um

- Width:<,=1600mm

- Item:Vacuum Bag

- Bag Variety:Back Seal Bags

- Model NO.:HK-B039

- Trademark:Hawking

- Origin:Hubei China

- HS Code:3920109000

- Production Capacity:500t,Month

=== Description ===

Temp Tolerance Range

Features:

1. Highly puncture-resistant, flexible and soft;

2. Good tensile properties;

3. Withstanding high temperatures up to 100ºC (boiling water);

And freezing temperatures as low as -45ºC;

4. High-barrier;

5. Good heat-sealing properties and tack;

6. With good tensile strength and heat-sealing strength;

7. With highly even film thickness;

8. High evenness of bags made by it.

Product Description

PE/PA/PE coextruded film is a symmetrical five-layer film, with excellent strength and puncture-resistance. Without biaxial stretch, coextruded PA film is superior in strength and puncture-resistance, compared with film with biaxial stretch. PE/PA/PE is more cost-effective than asymmetric membrane, but not as flat in bag making. Blown PE/PA/PE tube membrane can be made into sacks directly with least cost.Item

Our advantage:

1. Equipment:

We have the most advanced Germany W&H eleven-layer co-ectruded cast film production line.

2.Capacity Advantage:

Good equipment,extensive production experience,reasonable workshop planning,strong technique.

3. Materials:

All cast films are made of high-quality America and Japan import food grade raw materials.

4.Customer Maintenance:

One-to-one service,reply within 24 hours,communicate and visit exchange.

5. After Service:

We can prepare all documents you need, and solve all problems related to the current order.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23