Heat Sealing Pillow Pack Bags for Food Packaging

Wenzhou Co-Pack Co., Ltd. / 2022-06-09

- Raw Materials:High Pressure Polyethylene Plastic Bag

- Making Process:Composite Packaging Bag

- Shape:Special Bag

- Material:Laminated Material

- Function:Puncture Resistance

- Other:Hang Hole

=== Base Info ===

- Origin:Wenzhou

- Trademark:Any authorized trademark

- Specification:ISO 9001, SGS, HACCP

- Transport Package:Bundle-PE Bag-Carton-Tape-Pallet

- Model NO.:cp-hspp001

- HS Code:7607200000

- Production Capacity:500′000 PCS,Day

=== Description ===

Basic Info.

Model NO. cp-hspp001 Transport Package Bundle-PE Bag-Carton-Tape-Pallet Specification ISO 9001, SGS, HACCP Trademark Any authorized trademark Origin Wenzhou HS Code 7607200000 Production Capacity 500′000 PCS/DayProduct Description

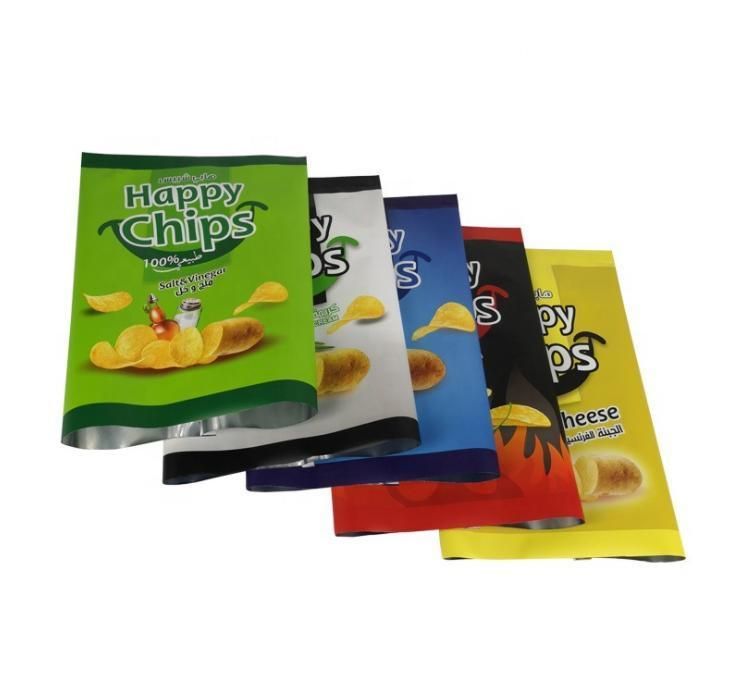

Heat Sealing Pillow Pack Bags for Food Packaging

Co-pack's pillow pack is the perfect pack for chips and other snack foods. It can be printed with high quality images through gravure or flexo graphics. A range of seal and barrier technologies can be incorporated to maintain product freshness.

| Product Material Type | Film laminates Aluminium foil laminates Paper laminates |

| Product Application | Confectionary; Cones & wafers; Herbs& spices; Infant Formula, powder; Jerry or Jello crystals; ready meals packet; sauce& gravy packet; soup; yeast; cookies; crackers; nutritious snacks; snack foods |

| Producing Process | 1.printing;2.laminating;3.slitting;4.packing |

| Quality Level | Food grade(including film, ink, glue and solvent) |

| Special Property | 1. Anti-counterfeiting 2. Local gloss/matt effect 3. Local demetalized window 4. Customerized on size, material type & design. |

| MOQ | 20000 PCS |

| Packing | Bundle-PE bag-carton-tape-pallet |

| Payment Terms | 30% deposit after confirmed design&contract,70% balance within 7 days after the goods left the seaport. |

| Delivery Time | 15 days after received deposit, also depends on the quantity. |

| Certificates | SGS,QS,ISO9001,HACCP |

| Note | Before quoting, pls give us detailed specifications which you have, such as design, size, material type etc. thanks. |

Features

1.Saving of packaging materials and associated cost(reel storage, environment taxes, secondary packaging)

2.High barrier protection if necessary

3.Customised shapes for differentiation

4.Great for product sampling and promotional packs

5.High quality image of the product.

6.Provided in reel form

Packaging Process

1.Automated VFFS packaging machine

Added Value

1.Highest quality solutions produced under established control systems

2.Rapid response dedicated and knowledgeable team of food scientists & technicians

3.Full service-design, creation and delivery

4.In-house environmental experts

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23