Cross Corner Loops PP Big Bags Laminated Polypropylene Bags

Chengda Pack Industry (Qingdao) Co., Ltd. / 2022-06-09

- Material:PP

- Shape:Square Bottom Bag

- Feature:Moisture Proof, Recyclable, Disposable, Shock Resistance

- Application:Food, Promotion, Household, Chemical, Apparel, Construction, Mineral, Agricultural Etcc

- Making Process:Plastic Packaging Bags

- Raw Materials:Polypropylene Plastic Bag

=== Base Info ===

- Top:Spout, Duffle, Open or as Per Request

- MOQ:200PCS

- UV:Treated

- Usage:Sand, Chemical, Building Material etc

- Swl:1000-1500kgs

- Bag Type:Tubular

- Loops:Cross The Bottom

- Delivery Time:30 Days for One Full Container

- Sf:5:1

- Certificate:ISO9001-2008,SGS,HACCP etc

- Color:White,Black or as Per Reqest

- Bag Variety:Circular

- Model NO.:QDCD-FIBC-25

- Bottom:Discharge,Flat as Per Request

- Transport Package:by Pallet or Bale as Per Request

- Specification:95x95x110cm

- Trademark:CD

- Origin:China

- HS Code:6305330090

- Production Capacity:2400000PCS,Year

=== Description ===

Basic Info.

Model NO. QDCD-FIBC-25 Bag Variety Circular Color White,Black or as Per Reqest Sf 5:1 Certificate ISO9001-2008,SGS,HACCP etc Delivery Time 30 Days for One Full Container Loops Cross The Bottom Bag Type Tubular Swl 1000-1500kgs Usage Sand, Chemical, Building Material etc UV Treated MOQ 200PCS Top Spout, Duffle, Open or as Per Request Bottom Discharge,Flat as Per Request Transport Package by Pallet or Bale as Per Request Specification 95x95x110cm Trademark CD Origin China HS Code 6305330090 Production Capacity 2400000PCS/YearProduct Description

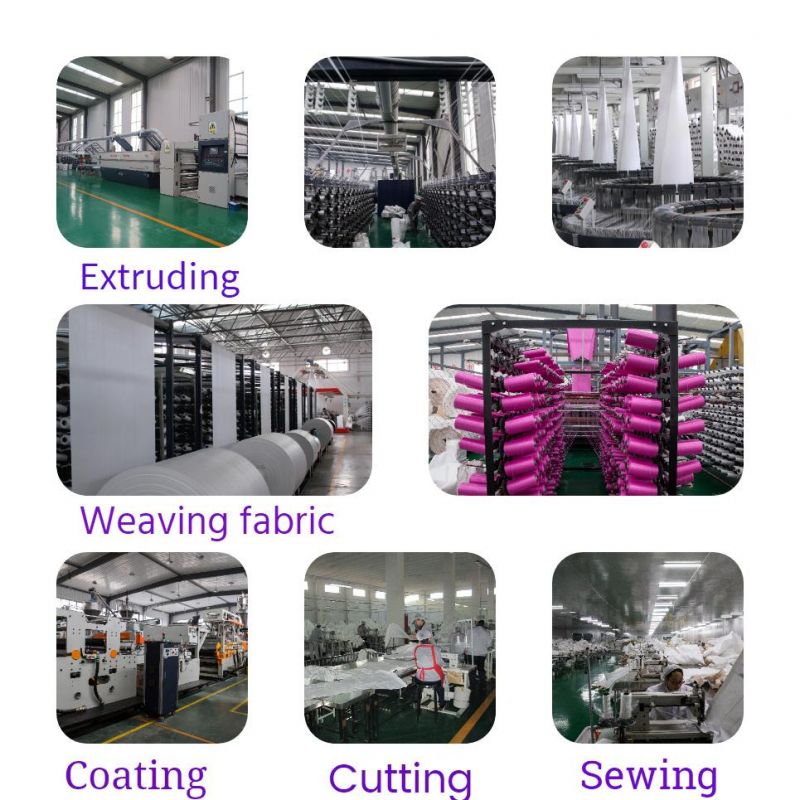

Flexible Intermediate Bulk Containers, also known as the big bag, ton bag, bulk bag, is generally made of polypropylene as the main raw material, extruded into film, drawing, and then woven, cut, and sling accessories. With this package, not only helps to improve the efficiency of loading and unloading, especially suitable for bulk powder, granular, bulk goods packaging, is conducive to promoting the standardization and seriation of bulk cargo packing, reduce transportation cost, but also has the advantages of convenient packaging, storage and low cost. It is especially suitable for mechanized operation. It is an ideal choice for storage, packaging and transportation. It can be widely used in the packaging of cement, chemical fertilizer, salt, sugar, chemical raw materials, ore and other bulk materials, such as highway, railway and sea transportation.

| Product name | FIBC Bulk Bags / pp bulk bags / jumbo bulk bags |

| Materials | 100% virgin polypropylene |

| Type of bag | U-panel / Tubular /4 panels / Round type |

| Size | Any size is available |

| Color | White, yellow, green, black or as per requests |

| Top | Full open/ with spout/with skirt cover |

| Bottom | Flat/discharge/full open |

| Sewing | Fold outside or inside sewing/chain/chain lock with filler cord |

| Lifting loop | Cross corner / Side seam / fully loop / loop in loop |

| Printing | One, two or four sides or as per requests |

| SWL | 500KG- 3000KGS |

| SF | 3:1, 5:1 or 6:1 |

| Package | 20pcs per bale, 150 pcs per pallet or as per requests |

| Feature | Breathable, anti-static, UV stabilization, reinforcement, dust-proof, moisture-proof |

| Delivery time | 15-35 working days per 40HQ |

| Advantages | Be easy to load and unload. Welcome to contact us for the bag, OEM order is welcome |

| MOQ | 200pcs |

| Payment terms | T/T, L/C or West Union is available |

Advantages:

1. 100% new virgin selected PP, purchased from international famous petrol products directly, high tension to avoid broken during working with forklift.

2. Properly surface treatment, can be stored in warehouse for more than 1 years.

3. A couple of machines work for 24 hours to ensure fast delivery time.

4. OEM service, experienced engineers design the FIBC bags according to different demand.

5. Fully inspection during production and sampling inspection before bale packing.

6. Low MOQ, any test order in low qty is welcomed.

7. Free sample will be provided for your evaluated.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23