5ml-15ml Wholesale Cosmetic Packaging D23mm Stright Round Clear and Amber Serum Essential Oil Tube Glass Bottle with Gold Aluminum Press Button Dropper Cap

DEMEI Industrial Limited / 2022-06-09

- Surface Handling:Screen Printing

- Shape:Round Bottle

- Sealing Type:Screw Cap

- Usage:Cosmetics, Personal Care Product

- Material:Glass

- Base Material:Glass

=== Base Info ===

- Transport Package:Shrink Bag-Carton-Pallet

- Product Name:3ml 5ml 8ml 10ml 12ml Clear Glass Dropper Bottle W

- MOQ:10000PCS

- Cap Color:Custom Made

- Industrial Use:Personal Care

- Printing:Screen Printing, Hot Stamping, Painted

- Use:Essential Oil

- Model NO.:wy3015

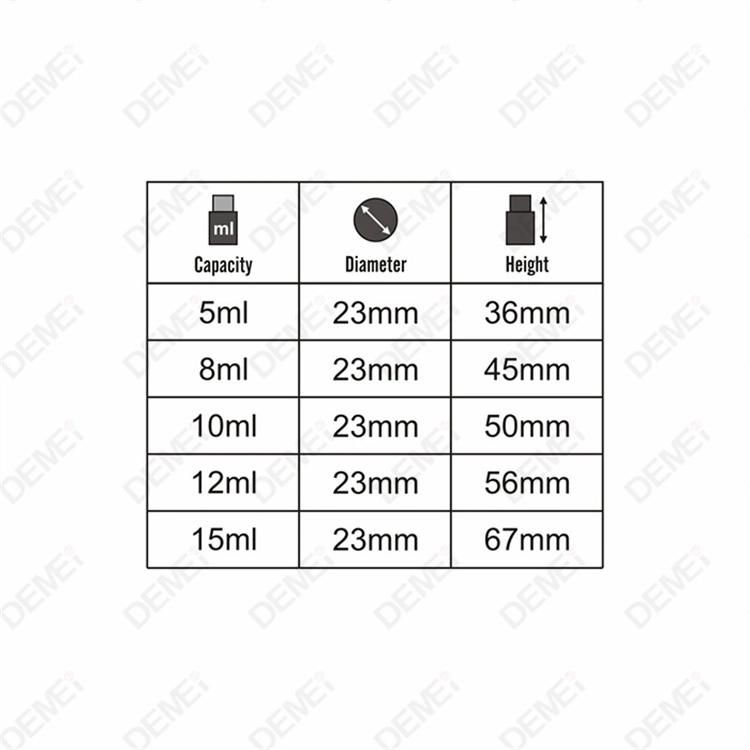

- Specification:5-20ml

- Trademark:Winpack

- Origin:China

- HS Code:7010909000

- Production Capacity:500000

=== Description ===

Basic Info.

Model NO. wy3015 Use Essential Oil Printing Screen Printing, Hot Stamping, Painted Industrial Use Personal Care Cap Color Custom Made MOQ 10000PCS Product Name 3ml 5ml 8ml 10ml 12ml Clear Glass Dropper Bottle W Transport Package Shrink Bag-Carton-Pallet Specification 5-20ml Trademark Winpack Origin China HS Code 7010909000 Production Capacity 500000Product Description

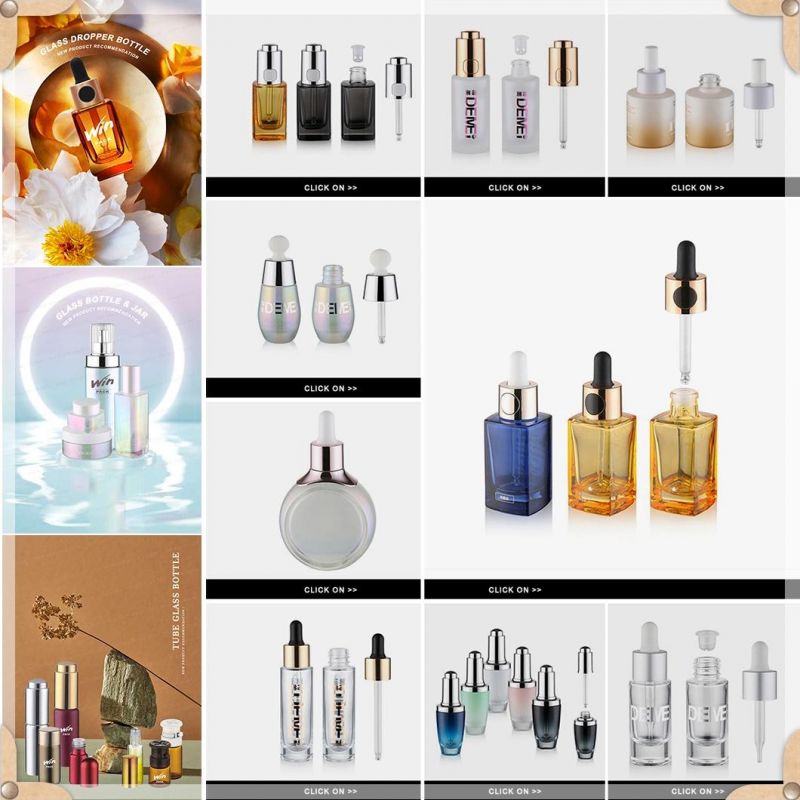

5ml-15ml wholesale cosmetic packaging D23mm stright round clear and amber serum essential oil tube glass bottle with gold aluminum press button dropper cap

China Manufacturer of quality bottles and Jars.

Customize cosmetic packaging Bottles including dropper bottle, essential oil bottle, roll on bottle, lotion bottle, bamboo bottle, foundation bottle, injection bottle, perfume glass bottle, as well as other glass jars and containers

Products Description:

| Material : | Glass |

| Production : | Machine made |

| Capacity: | Customized |

| Sealing Type: | Screw cap ,dropper, pump |

| Standard Glass Bottle MOQ | 5000 pcs |

| Decoration on bottle: | 1.Color coating 2.Frosted 3. Matt surface 4.Silkscreen printing 5.Gold plating ,etc |

| Packaging | Pallet or Carton packed |

| Sample lead time | 1-12 working days |

| Production mold lead time | 15-35 working days |

| Payment Terms: | T/T, Paypal, Credit Card, Western Union |

| Others Production: | Cap, Dropper and Pump, Paper Box,make up, Seal machine |

| Certificate: | ISO |

| Place of Origin | Anhui, China(Mainland) |

OUR KEY ADVANTAGE

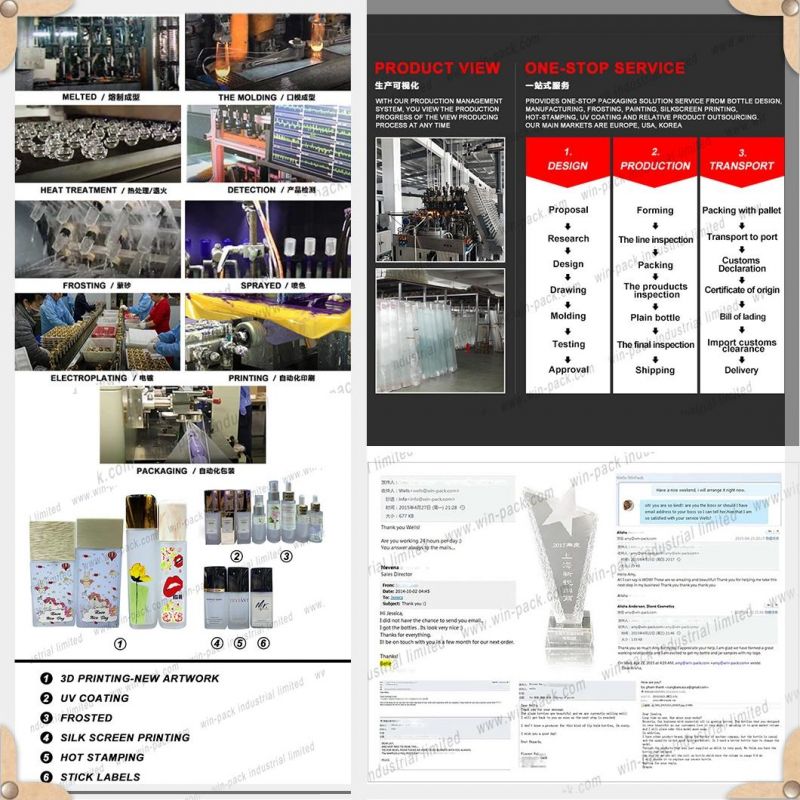

1.Strong manufacturing capacity and high standard quality control

With an installed capacity of 2,280 tons per day, makes us able to produce glass bottles and containers in any color.

QC,first happens at the IS machine, immediately after the bottle is formed. Here, the line operator, with the quality control checker, does hot end sampling for dimensional checks.

Hot-end ware rejection is an automatic process to ensure quality of the bottles after bottle swabbing. Next, the bottles are put into an annealing chamber, where they are gradually heated and cooled to de-stress.

The bottles then pass through a series of automatic and camera inspection checks by equipment These machines check for body defects, neck finish, bubbles, foreign matter etc.

The bottles are finally automatically shrink-wrapped, and a sample of the packed bottles is put through a QA process to check for defects.

2.DESIGN & ENGINEERING

Because each project is unique, we make a dedicated project team. DESIGN & ENGINEERING, who specializing in bottle and brand design from scratch, and the 3D PRINT PROTOTYPING which can rapid prototyping capabilities in-house.

3.Price of mass production private mold from 3,000 USD

In Europe and USA production of a private mold costs a fortune, sometimes reaching the level of 25,000 USD per mold set. However, due to lower labor costs and flexible production, here in China we set the record minimum price starting at 3,000 USD per mold set. Our molds can produce millions of bottles and whenever they wear out we replace the mold with new one free of charge. The cost of mold is refundable after 500,000 bottles ordered.

4.Minimum order quantity for custom design bottles only 10000 bottlesOur MOQ requirements for exclusive bottles, only 10000 bottles per run. That gives a great opportunity for the start ups and new projects to make a test run in the cosmetic market.

5.Only 30-35 working days from concept design to bottle mass production

Due to our flexibility and speed of operations we manage to do the efficient work in much shorter period of time, which saves our clients a great deal of time and money.

6.Significant cost advantages

Though the manufacturing of glass itself is highly automated, critical functions such as quality control need large teams of skilled professionals. Not surprisingly, the total cost of production in China, where manpower is among the cheapest in the world, is less than half of that in France and almost half of that in the US. With manufacturing facilities in North China, DEMEI Win-Pack is able to produce glass at significantly lower costs than its competitors in other parts of the world and deliver a sustainable cost advantage to customers.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23