Best Plastic Printing Packaging Food Bag

Wenzhou Co-Pack Co., Ltd. / 2022-06-09

- Making Process:Composite Packaging Bag

- Material:Laminated Material

- Shape:Special Bag

- Feature:Moisture Proof, Recyclable, Bio-Degradable, Disposable, Shock Resistance, Antistatic

- Application:Food, Promotion, Household, Snack

- Raw Materials:High Pressure Polyethylene Plastic Bag

=== Base Info ===

- Specification:ISO 9001, SGS, HACCP

- Transport Package:Bundle-PE Bag-Carton-Tape-Pallet

- Export Market:Gobal

- Thickness:Custom

- Other:Puncture Resistance

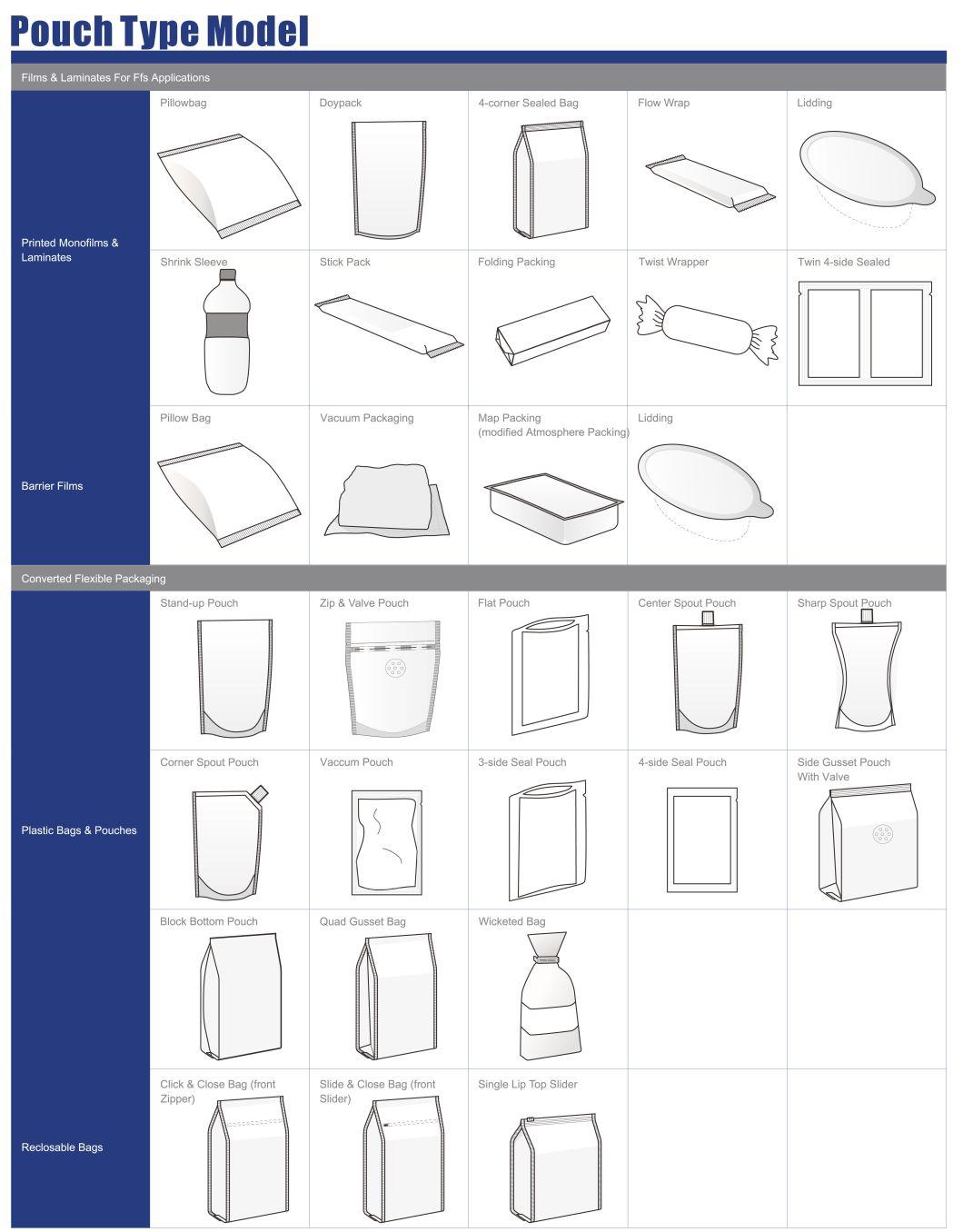

- Product Type:Stand up Pouch with Zipper

- OEM:Available

- Function:Anti-Counterfeiting

- Model NO.:cp-925+14

- Trademark:Any authorized trademark

- Origin:Wenzhou

- HS Code:3923290000

- Production Capacity:500′000 PCS,Day

=== Description ===

Basic Info.

Model NO. cp-925+14 Function Anti-Counterfeiting OEM Available Product Type Stand up Pouch with Zipper Other Puncture Resistance Thickness Custom Export Market Gobal Transport Package Bundle-PE Bag-Carton-Tape-Pallet Specification ISO 9001, SGS, HACCP Trademark Any authorized trademark Origin Wenzhou HS Code 3923290000 Production Capacity 500′000 PCS/DayProduct Description

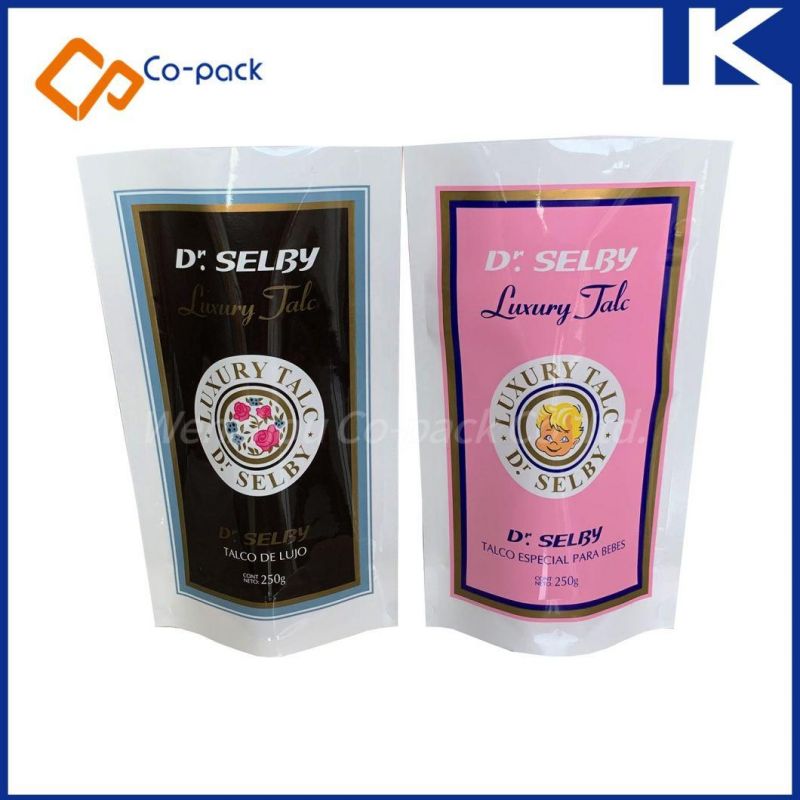

Laminated Stand up Plastic Food Packaging Bag

Our main plastic food packaging bags, contain: Laminated material bag, PE bag, BOPP bag, CPP bag, Aluminum foil bag, LDPE bag, PET bag, kraft paper bag, stand up pouch, spout pouch, zipper bag, three-sides sealed bag, gusset bag, shaped bag, packaging film and so on.

Stand up pouches are highly versatile, easy to use and stand out on a retail shelf. Lighter and lower in cost than rigid containers, they also offer ease of disposal. Laminates for stand up pouches are available for a wide range of products, from fresh produce and meat to home care and personal goods.

| Product Material Type | Aluminium Film laminate Multi layer laminate PVDC Paper laminates |

| Product Application | Breakfast and cereal bars; Cereals, ready to eat; Dry noodles & pasta; Oats; Rice; Cheese; Dairy desserts; Fresh milk Yoghurt; Coffee, ground and beans; Coffee, instant; Dried fruit Flours; Herbs & spices; Infant formula, powder; Jelly or Jello crystals Milk modifiers; Packet ready meals; Salt; Sauce and gravy, packet Soup, packet instant; Sugar; Sugar substitutes; Tea bags & loose; Yeast; Fresh value-added meats |

| Producing Process | 1.Roto printing;2.Laminating;3.Slitting;4.bag making;5.packing |

| Quality Level | Food grade(including film, ink, glue and solvent) |

| Special Property | 1. Anti-counterfeiting 2. Local gloss/matt effect 3. Local demetalized window 4. Customerized on size, material type & design. 5. zipper or spout can be added |

| MOQ | 20000 PCS |

| Packing | Bundle-PE bag-carton-tape-pallet |

| Payment Terms | 30% deposit after confirmed design&contract,70% balance within 7 days after the goods left the seaport. |

| Delivery Time | 15 days after received deposit, also depends on the quantity. |

| Certificates | SGS,QS,ISO9001,HACCP |

| Note | Before quoting, pls give us detailed specifications which you have, such as design, size, material type etc. thanks. |

Features

A. Safe and convenient

1. Easy opening (pre-laser cut) and reclosable (zip or spout)

2. Unbreakable

3. Minimises spillage

4. Microwavable

5. Easy to crush and fold for disposal

6. Reduced packaging weight, compared to rigid containers

B. Cost effective

1. Lower transport costs in comparison to rigid containers

2. Material cost advantage compared to can, glass, PET & cartons

C. Maintained freshness

1. High puncture resistance and stiffness

2. Excellent chemical resistance

3. Wide range of barrier levels possible (UV, water, gas)

4. Reduced heat treatment improves taste of product

D. Differentiating shelf presence

1. Attractive, unique presentation with large graphic area

2. Wide range of structures and finishes

3. Transparent window option

4. Optional features: Handle, Euro-slot, spout &cap

5. High product quality perception

E. Product samples option

1. Mini stand up pouches available

2. Lower cost alternative to sample bottles

3. Twice the liquid volume in comparison to a sachet of similar size

Packaging Process

1. Hand packing

2. Automated filling machine

Added Value

1. Highest quality solutions produced under established control systems

2. Rapid response dedicated and knowledgeable team of food scientists & technicians

3. Full service-design, creation and delivery

4. In-house environmental experts

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23