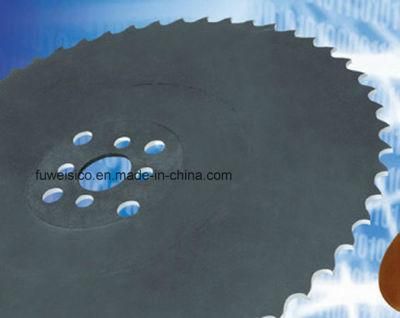

Best Quality Pipe Cutting Machine Blade 315 X 2.5 X 32mm 220T.

Zhejiang Alwsci Technologies Co., Ltd. / 2022-06-09

- Certification:ISO9001:2008, ISO9001:2000, RoHS, CE, SGS

- Tooth Form:BW,Hz,A,AW,BR

- Diameter:315mm

- Function:Cutting

- Shape:Circular Saw Blade

- Coating:Nitride Saw Blade

=== Base Info ===

- Model NO.:315x2.5x32mm 220T

- Type:HSS Saw Blade

- HRC:HRC62-65

- Appllication:Metal Cutting

- Material:HSS M2,HSS M35

- Delivery Time:4-6 Weeks After Order

- Transport Package:10PCS Per Carton

- Specification:315x2.5x32mm 220T

- Trademark:FUWEISI, BOSS CUT

- Origin:China, Germany, Japan, USA Material

- HS Code:8202399000

- Production Capacity:60000PCS,Month

=== Description ===

Ready stock.275x2.5x32mm Z=180/200/220/240/260 300x2.5x32mm Z=180/200/220/240/260 315x2.5x32mm Z=180/200/220/240/260 350x2.5x32mm Z=180/200/220/240/260 370x2.5x32mm Z=180/200/220 400x3.0x32mm Z=160/200/220 425x3.0x32mm Z=160/180/200 450x3.0x32mm Z=120/160/180/200 500x4.0x32mm Z=80/100/120/160

Technical data ot TiN coating:

Colour: Gold

Process: PVD

Hardness: 2500HV

Friction: 0.4

Thickness: 1-4mm.

Max cutting temperature: 600 degree.

Operation:

Structural steel

Alloyed steels

Steel pipes and profiles

Pipes and profiles out non ferrous metals

Technical recommendation:

Raising of the coating hardness by reducing the friction

Universal coating for better sawblade life

50-100%higher speed and feed rates

Prevention of side pick-UPS

Production is based on DIN standards 1836, 1837, 1838 and 1840, extended by the refined "FUWEISI " manufacturing standards. The delivery program consists of a range of standard sawblades which can be delivered from stock and a range of special sawblades to be produced to customer specifications.

The HSS Steam-treated sawblades are supplied as standard in high speed steel grade M2 = DIN 1.3343.

This is currently the most common surface treatment for circular saw blades. It is not a PVD treatment, but controlled oxidation that produces a layer of iron oxide (Fe3O4) on the surface, which increases the self-lubricating capability of the blade. It is used for general cutting work, except for aluminium, copper, brass and their alloys due to the chemical incompatibility which sometimes occurs.

All the products haven been enjoying an excellent reputation in the world market for it's competitive price and excellent quality.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23