Carbide Rotary Burrs Type a

Xuzhou Shangli Artware Co., Ltd. / 2022-06-09

- Application:Grinding Machine

- Standard:Standard

- Coating:Coating

- Material:Tungsten Steel

- Type:Cutter

- Work Type:Cut off

=== Base Info ===

- Model NO.:metric and inch

- Transport Package:Single Piece in Plastic Tube

- Specification:3mm to 25mm

- Trademark:stc

- Origin:Zhenjiang

- HS Code:82075090

- Production Capacity:10000

=== Description ===

Basic Info.

Model NO. metric and inch Transport Package Single Piece in Plastic Tube Specification 3mm to 25mm Trademark stc Origin Zhenjiang HS Code 82075090 Production Capacity 10000Product Description

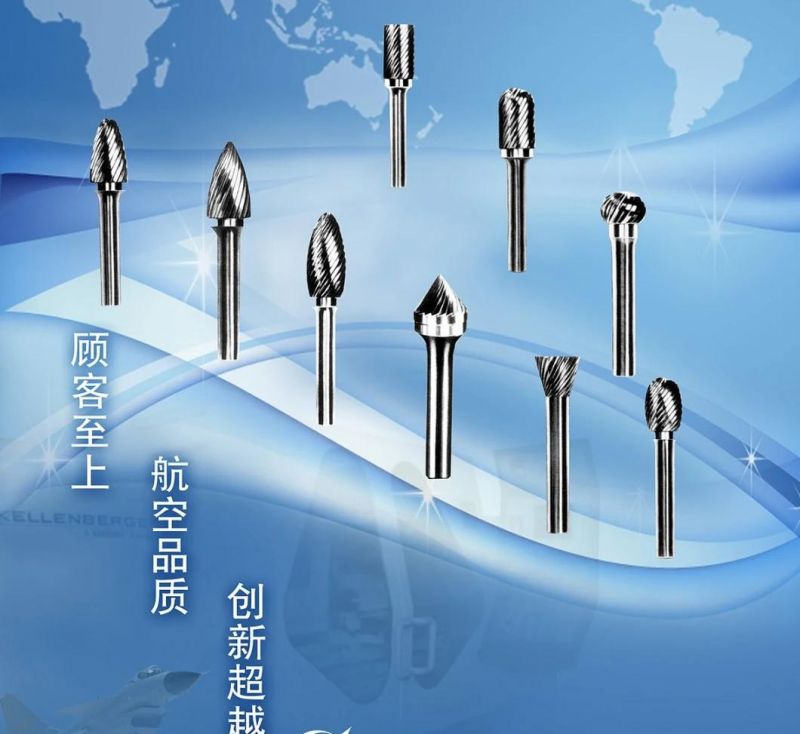

OUr carbide burs are made of tungsten carbide, a metal that is extremely hard (about three times stiffer than steel) and can withstand high temperatures. Because of their hardness, carbide burs can maintain a sharp cutting edge and be used many times without becoming dull. However, carbide burs are brittle and have a tendency to fracture under pressure. They are best operated at high speeds with light pressure.

OUr carbide burs are made of tungsten carbide, a metal that is extremely hard (about three times stiffer than steel) and can withstand high temperatures. Because of their hardness, carbide burs can maintain a sharp cutting edge and be used many times without becoming dull. However, carbide burs are brittle and have a tendency to fracture under pressure. They are best operated at high speeds with light pressure.Carbide burs are used most commonly for excavating and preparing cavities, finishing cavity walls, finishing restoration surfaces, drilling old fillings, finishing crown preparations, contouring bone, removing impacted teeth, and separating crowns and bridges. Carbide burs are defined by their shank and by their head. The type of handpiece being used determines which type of shank is needed. The procedure to be performed determines the type of cutting design/head shape that is chosen.

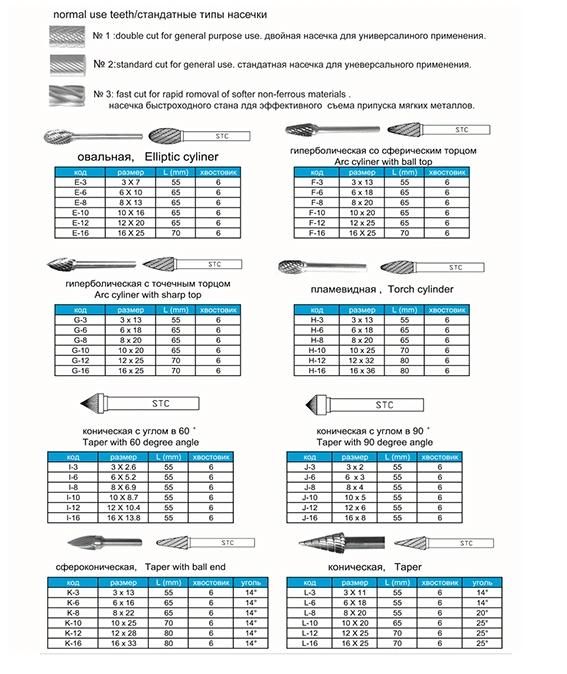

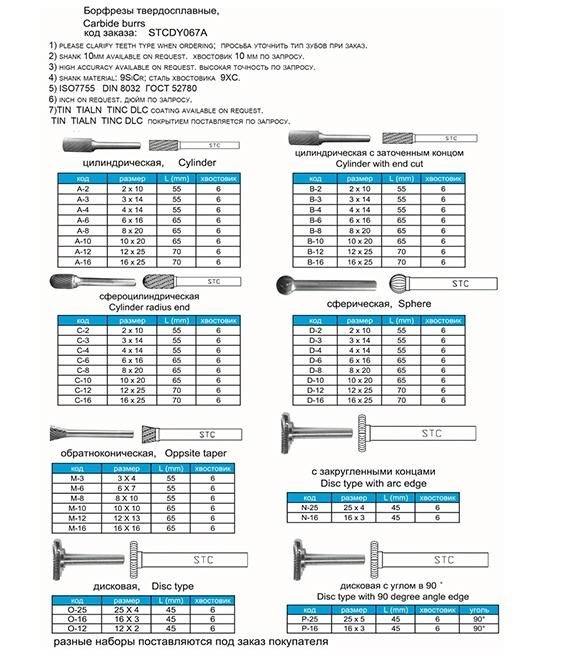

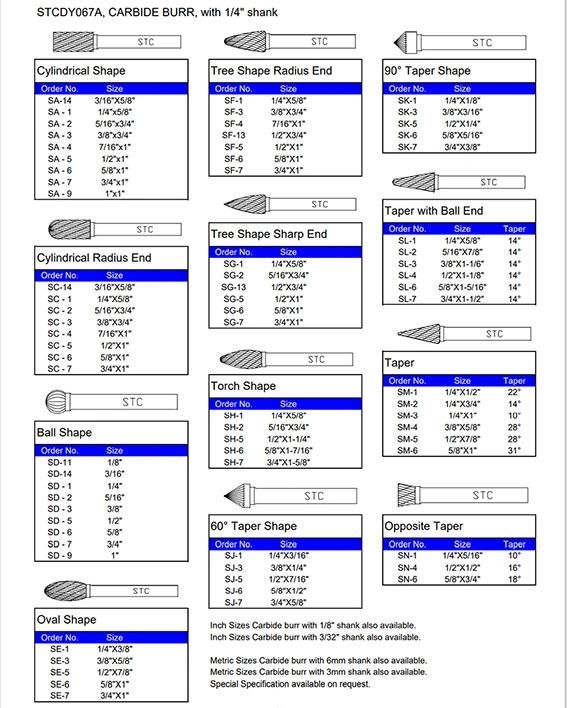

| diameter | flute length | total length | shank |

| mm | mm | mm | mm |

| 4 | 13 | 40 | 3 |

| 5 | 13 | 40 | 3 |

| 6 | 13 | 48 | 3 |

| 6 | 16 | 65 | 6 |

| 8 | 20 | 65 | 6 |

| 10 | 20 | 65 | 6 |

| 12 | 25 | 65 | 6 |

| 16 | 25 | 65 | 6 |

| 20 | 25 | 70 | 8 |

| 25 | 25 | 70 | 8 |

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23