OEM Precision Stainless Steel Investment Casting Gear

Shaoxing Shangyu Jiaozi Plastic Packaging Products Co., Ltd. / 2022-06-27

- Application:Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car

- Hardness:Hardened

- Gear Position:Internal Gear

- Manufacturing Method:Cut Gear

- Toothed Portion Shape:Spur Gear

- Material:Stainless Steel

=== Base Info ===

- Model NO.:CFM-1002

- Type:Worm And Wormwheel

- Origine:Qingdao

- Certificate:ISO9001, SGS Ce

- Brand:Chifine

- Service:OEM and ODM

- Machining:CNC Turning Milling Drilling Lathe

- Delivery Time:30 Days After Receiving The Payment

- Supply Ability:10000 Piece,Pieces Per Week

- Manipulate Way:Robotics

- Manufacturer:Yes

- Quality Control:Professional QC and Test Equipment

- Transport Package:Pallet, Manmade Wooden Case or as Your Requirement

- Specification:Investment Casting Gear

- Trademark:Chifine

- Origin:Jimo Qingdao

- HS Code:7307190000

- Production Capacity:150 Tons Per Month

=== Description ===

Basic Info.

Model NO. CFM-1002 Type Worm And Wormwheel Origine Qingdao Certificate ISO9001, SGS Ce Brand Chifine Service OEM and ODM Machining CNC Turning Milling Drilling Lathe Delivery Time 30 Days After Receiving The Payment Supply Ability 10000 Piece/Pieces Per Week Manipulate Way Robotics Manufacturer Yes Quality Control Professional QC and Test Equipment Transport Package Pallet, Manmade Wooden Case or as Your Requirement Specification Investment Casting Gear Trademark Chifine Origin Jimo Qingdao HS Code 7307190000 Production Capacity 150 Tons Per MonthProduct Description

Cast steel gear1.gear manufacturing

2.Helical gear

3.Cylindrical gear

4.Nonstandard.High quality with competitive price

Auto Gears for castings. investment castings & machine parts

Professional foundries with strong machining capacity

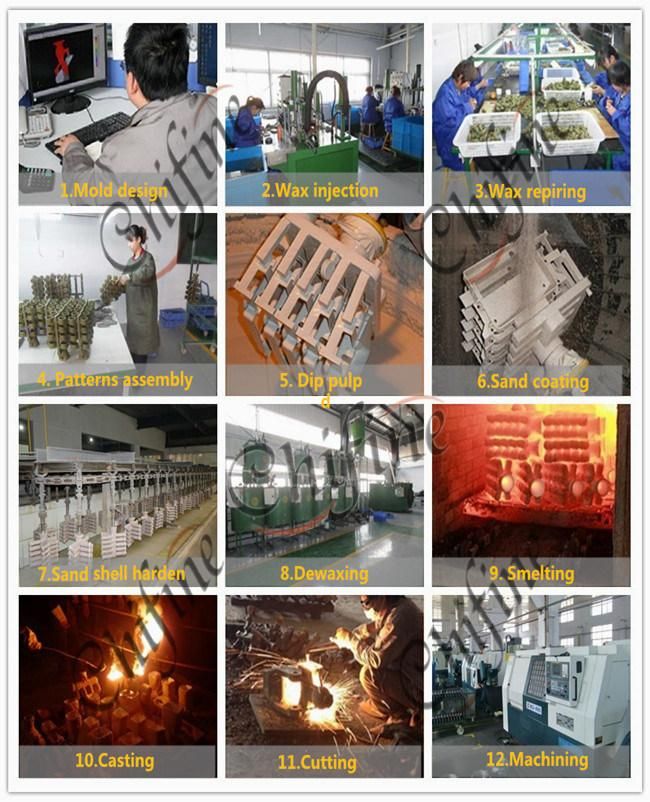

1) Lost Wax Process: Wax Injection, Wax Welding, Dipping, Sand-Coating, Shell-Making, Dewaxing, Cleaning, Pouring, Cutting

2) Materials: carbon steel, alloy steel, cast iron, cast steel, pig iron, grey iron, ductile cast iron and so on

3) Has obtained international approvals ISO9001, TUV-PED,BV

4) Produced by experienced technical staff

5) Small orders accepted

6) Production capacity: more than 3,000MT per year

7) Perfect test facilities

8) Advanced Machining Equipment

9) Material standards:GB,DIN,EN,NF,ISO,JIS,SS,BS,AISI,SAE,ASTM,UNS,ACI.a

Company introdution:

1. Our company has advanced production equipments and all kinds of inspection equipments.

2. Strict quality control and manufacture process

3. Our business scope includes casting parts, forging parts, CNC machining parts, powder metallurgy and wire EDM.

4. We have over 15years experience.

Inspection:

1. The whole quality control management has been strictly carried out from raw material coming to final products

2. Third party inspection available upon requirement.

Our Main Export Market:

Exported to U.S.A, U.K, Germany, Italy, Japan, Swiss, Australia, Korea, and Southeast Asia and get good credits form them. All of products are manufactured in accordance with the U.S, Japan and Germany standards.

Our target:

To supply top quality products with reasonable price, circumspect and satisfactory service with Punctual delivery time.

Our Competitive Advantages:

1. 15 years' experience in forging part

2. Disciplined staffs and scientific operation;

3. Product performance;

4. Advanced producing and inspecting equipments;

5. Prompt Delivery;

6. Quality control system:ISO 9001:2000& 14001:2004&TS16949

7. Best Service

| product name | precision casting |

| material | stainless steel,carbon steel,alloy steel,special steel ect. |

| brand name | Chifine |

| products range | aerospace parts,hardware parts,medical equipments parts,sewing machines parts,automobile parts. |

| superior finish | RA1.6-6.3 |

| casting weight | 5g-15kg |

| length range | within 400 mm |

| main markets | Europe and the United States, Japan and other places |

| dimension accuracy | CT4-CT6 |

| mold process | investment casting,investment casting machine parts |

| process | punching,trimming,molding |

| application | machine parts |

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23