At10 Flex PU Timing Belt Synchronous Belt Truly Endless with Steel Cord

The Yk Technology Co., Ltd / 2022-06-27

- Standard or Nonstandard:Standard

- Application:Textile Machinery, Garment Machinery, Conveyer Equipment, Packaging Machinery, Electric Cars, Food Machinery, Marine, Mining Equipment, Agricultural Machinery

- Feature:Flame-Retardant, Anti-Static, Oil-Resistant, Cold-Resistant, Corrosion-Resistant, Heat-Resistant, Alkali-Resistant, Skid-Resistance, Wear-Resistant, Acid-Resistant, High Temperature-Resistance

- Tensile Strength:Strong

- Material:PU

- Type:Toothed Belt

=== Base Info ===

- Model NO.:AT10

- Materials:PU

- Model:At10

- Pitch:10mm

- Color:Transparent

- Cord:Steel, Kevlar

- Max Width:150mm

- Length:150-2380mm

- Teeth Number:25-238

- Transport Package:Export Standard

- Specification:AT10

- Trademark:UNI Belting

- Origin:Shanghai China

- HS Code:3926901000

- Production Capacity:20000000 Meters

=== Description ===

Basic Info.

Model NO. AT10 Materials PU Model At10 Pitch 10mm Color Transparent Cord Steel, Kevlar Max Width 150mm Length 150-2380mm Teeth Number 25-238 Transport Package Export Standard Specification AT10 Trademark UNI Belting Origin Shanghai China HS Code 3926901000 Production Capacity 20000000 MetersProduct Description

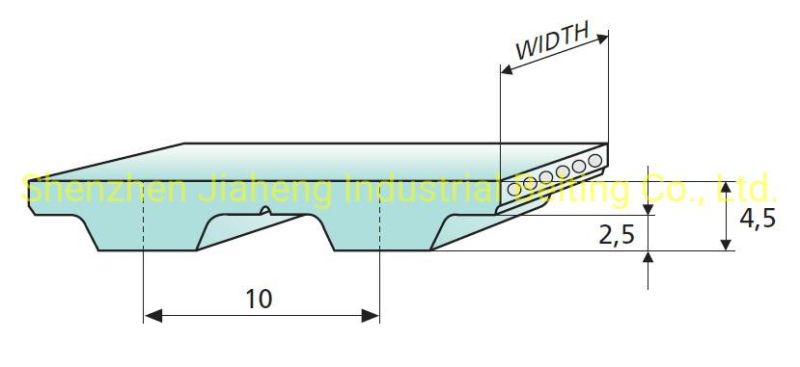

PU Synchronous belt AT10

PU Synchronous belts are manufactured in thermoset polyurethane by a unique moulding process. The high-grade polyurethane gives superior wear and abrasion resistance. Several types of cords, helicoidally rolled up inside the belts, assure excellent dimensional stability and offer high performances in terms of flexibility and traction resistance.

Model: AT10

- Pitch:10 mm

- Cord:Steel, Kevlar

- Max production width:150mm

- Power transmission: ≤ 70 Kw

- Rotational speed: approx.10000RPM

- Peripheral speed: approx.60MS-1

- Timing pulleys:from teeth= 15

Mechanical Features

- Consistent dimensional stability

- Low pre-tension

- Low noise

- High abrasion resistance

- Low maintenance

- High flexibility

- The max linear velocity can reaches 80m/second

Typical applications:

- Food processing

- Office automation equipments

- Swimming pool cleaning robots

- Automatic sliding doors and garage opening system

- Automated handling devices

- Linear drivers

- Positioning system

- Electric appliance I

- Textile Industry

- Wood Machine Industry

- Stone and marble Industry

- Paper and Printing

- DIY equpiments

- Chemist and pharmaceutical industry

- Robotic arms

We are a leading manufacturer of innovative thermoplastic polyurethane power transmission. All polyurethane belts are made out of abrasion-resistant polyurethane that provides thermoplastic flexibility, and long-lasting, energy efficient belt system solutions for even the most demanding industries and applications.

Uni belting has always been on the edge of innovation, making it a global leader in high-end, high-precision and high quality products, while at the same time ensuring a smooth operation on the machines.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23