Steel Metal Reduction Starter Shaft Spline Pinion Custom Precision Machine Transmission Wheel Planetary Sun Drive Spiral Helical Gear

Ningbo Ezfocus Co., Ltd. / 2022-06-27

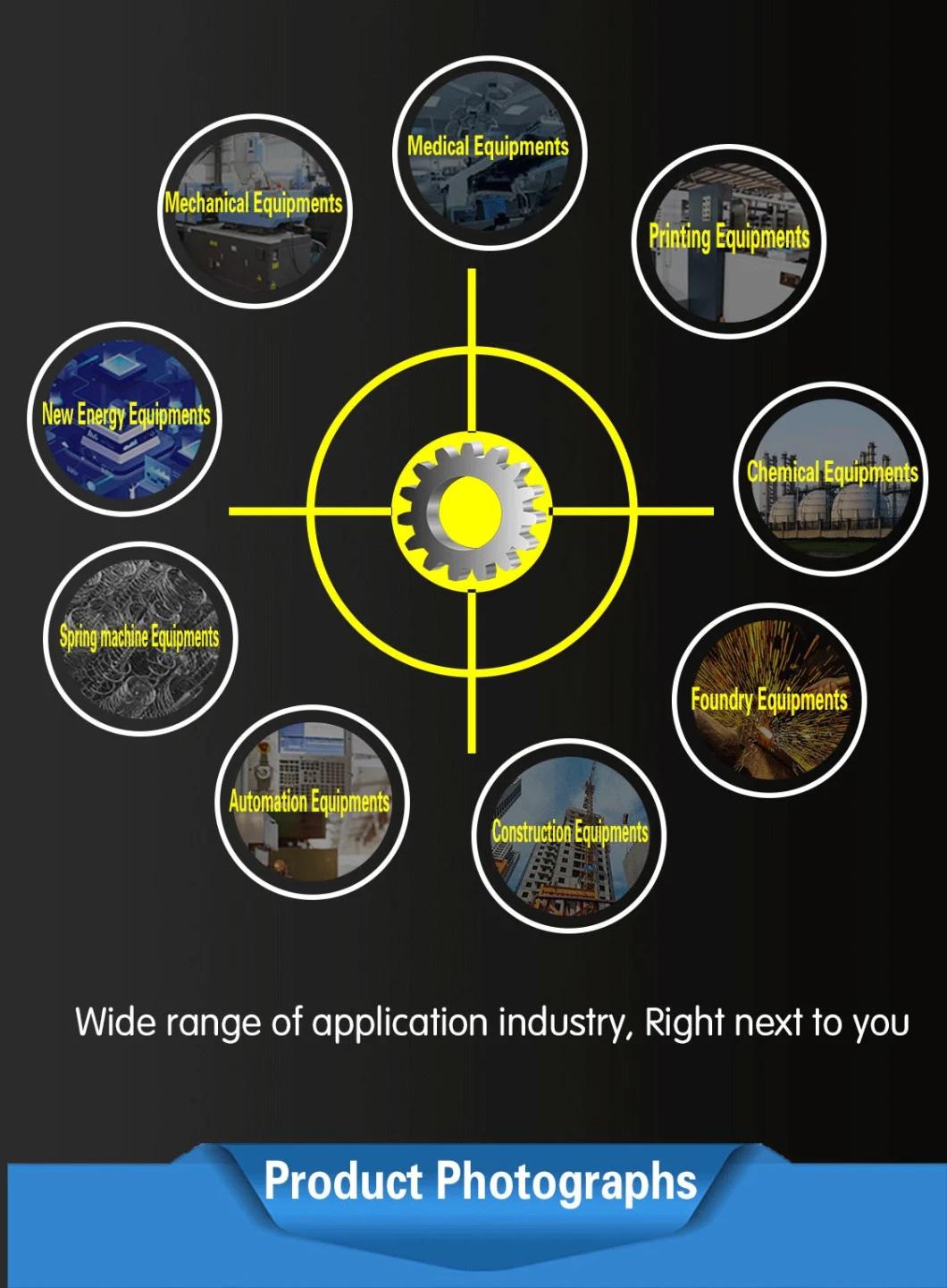

- Application:Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car

- Hardness:Hardened Tooth Surface

- Gear Position:External Gear

- Manufacturing Method:Cut Gear

- Toothed Portion Shape:Spur Gear

- Material:Steel Aluminum Brass Copper Plastic

=== Base Info ===

- Model NO.:CF-4

- Type:Circular Gear

- Module:0.1 .02, 0.4, 0.5,0.6,0.7,0.8,0.9,1, 1.5, 2 3 etc

- Pressure Angle:20 Degree

- Teeth Shape:Cylindrical Helical Gear

- Cog Wheel:Gear Wheel

- Dimension Tolerances:-,+0.01mm

- Noise:Low Noises

- Silence:40 to 60 Decibels

- Pitch Diameter:OEM Gears

- Pinion:Pinion Gear

- Lubricating:Lubricating Oil

- Power Tool:Power Drived Gear

- Reduction Ratio:Reduction Ratio 2:5

- Custom:Drawings From Customers

- Quality Standard:JIS, DIN and Agma

- Teeth Type:Toothed Straight Teeth Gear

- Transport Package:PP Bags and Cartons

- Specification:20 teeth 30 teeth 40 teeth 60 teeth

- Trademark:Q&c and OEM ODM

- Origin:Dongguan China

- HS Code:84834090

- Production Capacity:1000000,Month

=== Description ===

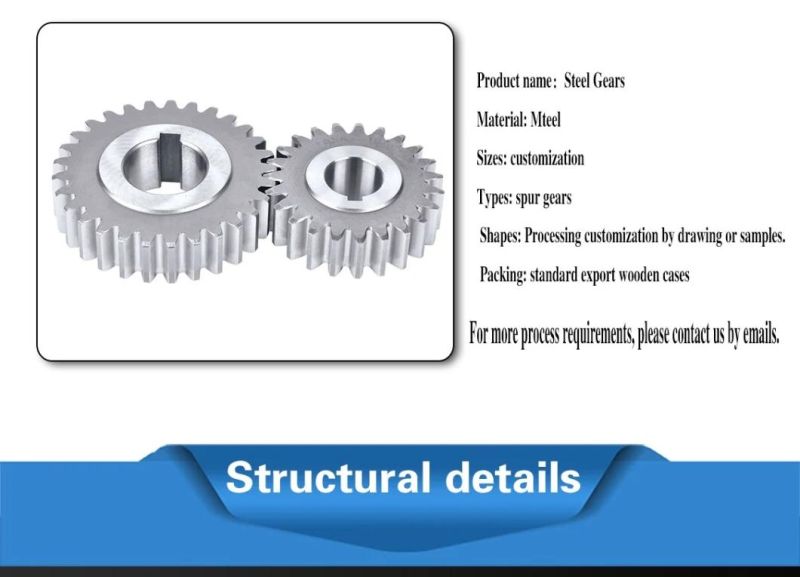

Basic Info.

Model NO. CF-4 Type Circular Gear Module 0.1 .02, 0.4, 0.5,0.6,0.7,0.8,0.9,1, 1.5, 2 3 etc Pressure Angle 20 Degree Teeth Shape Cylindrical Helical Gear Cog Wheel Gear Wheel Dimension Tolerances -/+0.01mm Noise Low Noises Silence 40 to 60 Decibels Pitch Diameter OEM Gears Pinion Pinion Gear Lubricating Lubricating Oil Power Tool Power Drived Gear Reduction Ratio Reduction Ratio 2:5 Custom Drawings From Customers Quality Standard JIS, DIN and Agma Teeth Type Toothed Straight Teeth Gear Transport Package PP Bags and Cartons Specification 20 teeth 30 teeth 40 teeth 60 teeth Trademark Q&c and OEM ODM Origin Dongguan China HS Code 84834090 Production Capacity 1000000/MonthProduct Description

reduction planetary starter drive machine transmission precision pinion involute transmission spiral helical gear| Item | Customized machined machining gears | |

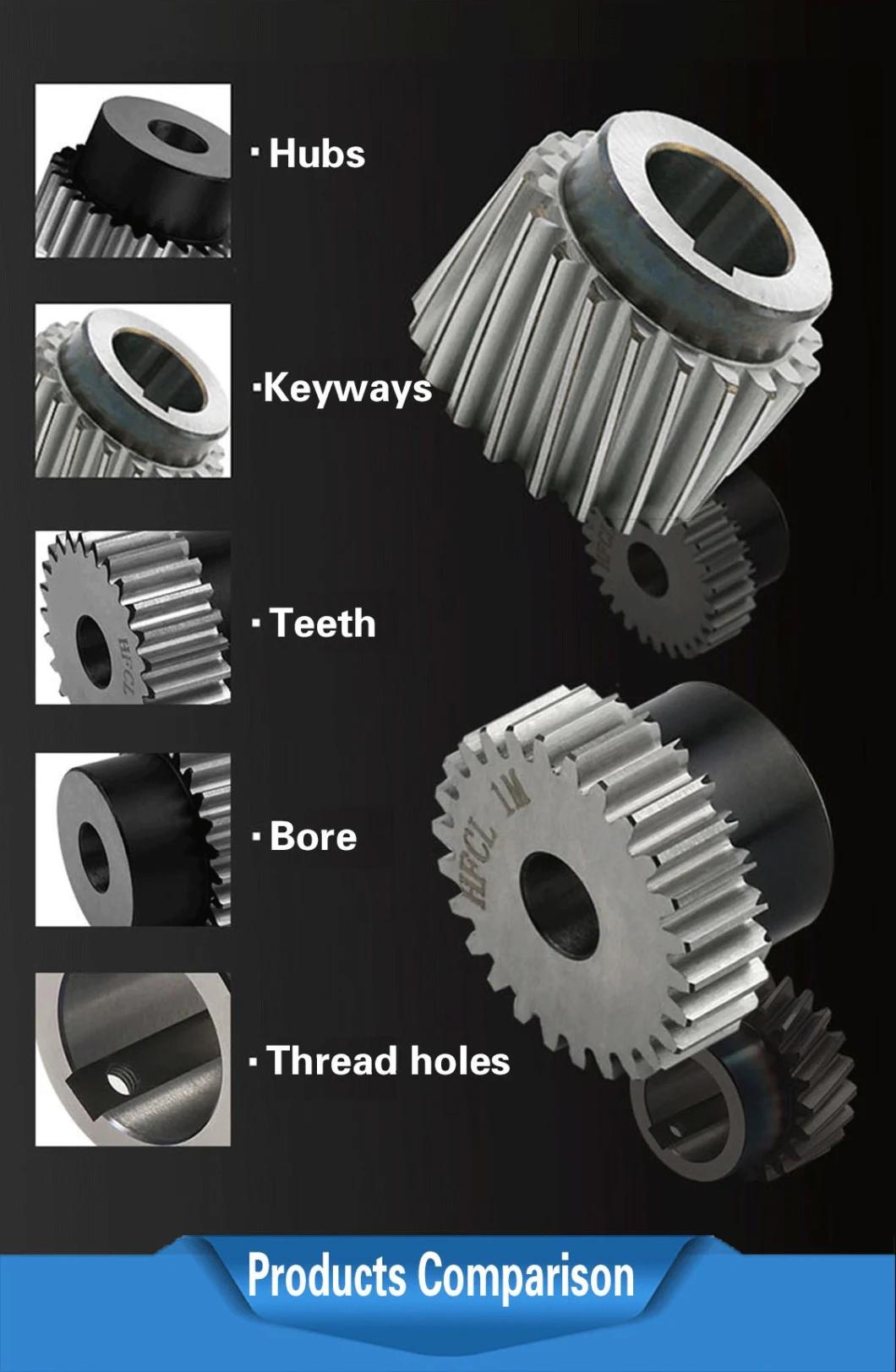

| Process | CNC machining,CNC milling, cnc lathe machining | |

| material | steel, stainless steel, carbon steel,brass,C360 brass copper, aluminum 7075,7068 brass,C360 brass copper, aluminum Nylon, PA66, NYLON , ABS, PP,PC,PE,POM,PVC,PU,TPR,TPE,TPU,PA,PET,HDPE,PMMA etc | |

| Quality Control | ISO9001 and ISO14001 | |

| Dimension bore tolerances | -/+0.01mm | |

| Quality standard | AGMA, JIS, DIN | |

| Surface treatment | Blackening, plated, anodizing, hard anodizing etc | |

| Gear hardness | 30 to 60 H.R.C | |

| Size/Color | Gears and parts dimensions are according to drawings from customer, and colors are customized | |

| Surface treatment | Polished or matte surface, painting, texture, vacuum aluminizing and can be stamped with logo etc. | |

| Dimensions Tolerance | ±0.01mm or more precise | |

| Samples confirmation and approval | samples shipped for confirmation and shipping cost paid by customers | |

| Package | Inner clear plastic bag/outside carton/wooden pallets/ or any other special package as per customer's requirements. | |

| Delivery Time | Total takes 2~~8weeks usually | |

| Shipping |

Production:

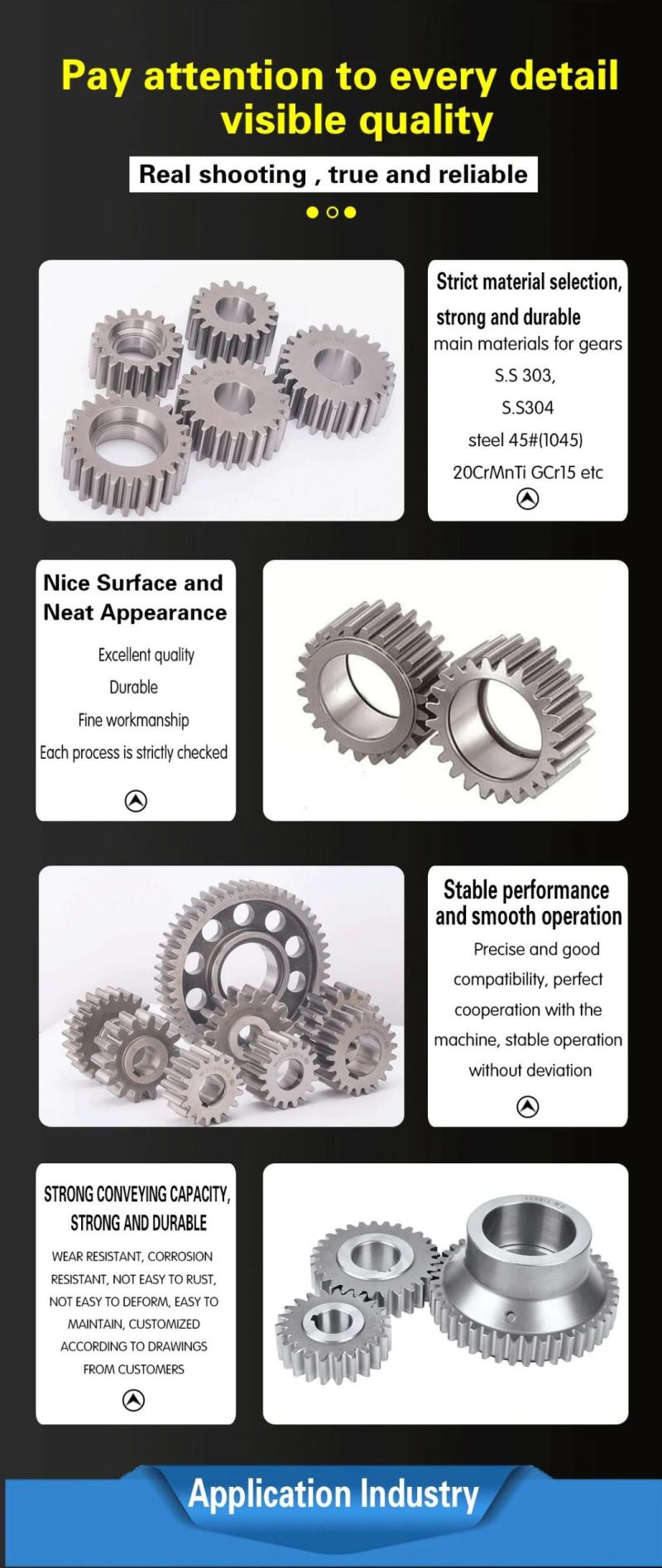

1. The workers are trained to inspect the gears and notice any defect in production in time.

2. QC will check 1pcs every 100pcs in CNC machining, and gears will meet all dimension tolerances.

3. Gears will be inspected at every step, and gears will be inspected before shipment, and all inspection records will be kept in our factory for three years.

4. Our sales will send you pictures at every gears production steps, and you will know the detailed production status, and you can notice any possibility of mistake, for our sales, QC and workers are keeping close watch on all production.

5. You will feel us working very carefully to assure the quality and easy to work with,

6. we cherish every inquiry, every opportunity to make gears and parts and cherish every customer.

QUALITY CONTROL PROCESS:

1) Inspecting the raw material --IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control (IPQC)

4) Checking the gears after production finished---- (FQC)

5) Checking the gears after they are finished-----Outgoing quality control (OQC)

Service:

1. Molds designs as per customers' gears drawing;

2. Submitting molds drawings to customers to review and confirm before mols production.

3. Providing samples with whole dimensions and cosmetic inspection report, material certification to customers.

4. Providing inspection report of important dimensions and cosmetic in batches parts.

Packing and shipment:

1. Gears are well and carefully packed in PP bags in CTNS, strong enough for express shipping, air shipment or sea shipment.

2. Air shipment, sea shipment or shipment by DHL, UPS, FedEx or TNT are availabe.

3. Trade terms: EXW, FOB Shenzhen, or CIF

4. All shippings will be carefully arranged and will reach your places fast and safely.

FAQ

Q1: How to guarantee the Quality of gears and parts?

We are ISO 9001:2008 certified factory and we have the integrated system for industrial parts quality control. We have IQC (incoming quality control),

IPQCS (in process quality control section), FQC (final quality control) and OQC (out-going quality control) to control each process of industrial parts prodution.

Q2: What are the Advantage of your gears and parts?

Our advantage is the competitive and reasonable prices, fast delivery and high quality. Our eployees are responsible-oriented, friendly-oriented,and dilient-oriented.

Our industrial parts products are featured by strict tolerance, smooth finish and long-life performance.

Q3: what are our machining equipments?

Our machining equipments include plasticn injection machinies, CNC milling machines, CNC turning machines, stamping machines, hobbing machines, automatic lathe machines, tapping machines, grinding machines, cutting machines and so on.

Q4: What shipping ways do you use?

Generally, we will use UPS DHL or FEDEX and sea shipping

5: What materials can you process?

For plastic injection gears and parts, the materials are Nylon, PA66, NYLON with 30% glass fibre, ABS, PP,PC,PE,POM,PVC,PU,TPR,TPE,TPU,PA,PET,HDPE,PMMA etc.

For metal and machining gears and parts, the materials are brass, bronze, copper, stainless steel, steel, aluminum, titanium plastic etc.

Q6: How long is the Delivery for Your gears and parts?

Generally , it will take us 15 working days for injection or machining, and we will try to shorten our lead time.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23