Heavy Machinery Spray Painting Room with Floor Conveyor Chain

Hangzhou Mig Packaging Co., Ltd. / 2022-06-23

- Type:Spray Booth

- Certification:CE

- Substrate:Steel

- Coating:Powder Coating

- Airflow Direction:Side Downdraft

- Heating Mode:Gas Heating

=== Base Info ===

- Paint Mist Treatment:Dry-type

- Condition:New

- Plenum (Height):800mm

- Extraction Area:24m2

- Walls:60mm Rock Wool Walls

- Brightness:>1,000lux

- Air Volume:2*35,000m3,H

- Empty Loaded Air Speed:0.20m,S

- Heats:2*315kw Heat Exchanger

- Maximum Working Temperature:80 Celsius

- Inverter:Schneider

- Noise:<78 dB

- Warranty:2 Years

- Stack Light:Yes

- Rated Power:50kw

- Transport Package:Cargo Loaded on Steel Frame Handled by Forklifts

- Specification:16000 X 6000 X 5500mm (L X W X H)

- Trademark:INFITECH

- Origin:Guangzhou, China

- HS Code:8419899090

- Production Capacity:1000 Sets,Year

=== Description ===

Basic Info.

Paint Mist Treatment Dry-type Condition New Plenum (Height) 800mm Extraction Area 24m2 Walls 60mm Rock Wool Walls Brightness >1,000lux Air Volume 2*35,000m3/H Empty Loaded Air Speed 0.20m/S Heats 2*315kw Heat Exchanger Maximum Working Temperature 80 Celsius Inverter Schneider Noise <78 dB Warranty 2 Years Stack Light Yes Rated Power 50kw Transport Package Cargo Loaded on Steel Frame Handled by Forklifts Specification 16000 X 6000 X 5500mm (L X W X H) Trademark INFITECH Origin Guangzhou, China HS Code 8419899090 Production Capacity 1000 Sets/YearProduct Description

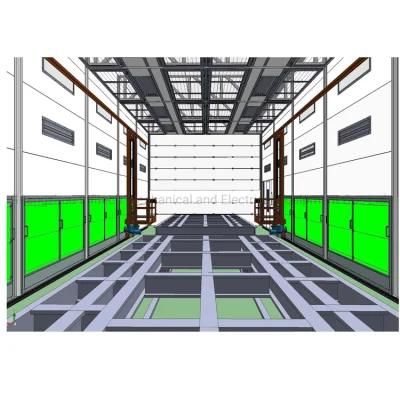

Heavy Machinery Spray Painting Room with Floor Conveyor Chain1.FEATURES

The paint booth is designed for painting and drying heavy duty products such as heavy machinery, large equipment etc.

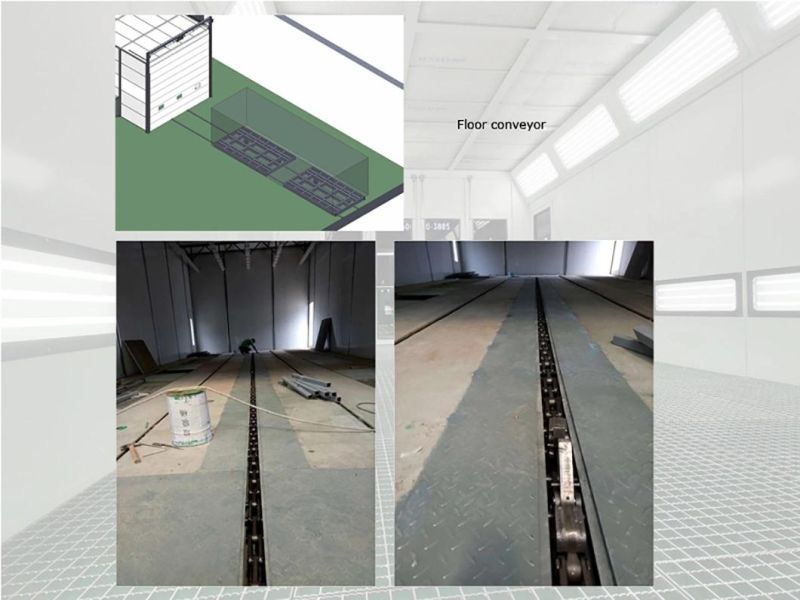

It has one electric entry door and one electric exit door. And it comes with floor conveyor system. The products are conveyed to the inside of the paint booth through the floor conveyor from one end. After painting and baking, the products are conveyed to the outside from the other end. The use of the conveying system facilitates the faster workflow and easier conveyance of the heavy duty products.

The airflow is side downdraft, with exhaust plenum chambers on both sides.

There are 2 sets of 2x11kw generator units for the booth.

As the manufacturing process, and requests for different products are different, Infitech is prepared to cater the industrial paint booths to your needs. And Infitech takes pride in delivering customized paint booth projects that best suit actual requirements, while also maximize profits for shop owners. Welcome to contact us for business.

2.SPECIFICATIONS

| ITEMS | SPECIFICATIONS |

| Product | Paint Booths with Conveyor Chain |

| Design standard | BS EN 13355: 2004 + A1: 2009 BS EN 60204: 2006 + A1: 2009 |

| Internal dimensions | 16000 X 6000 X 5500mm (L X W X H) |

| External dimensions | 16160 X 9370 X 6300mm (L X W X H) |

| Airflow | Side downdraft |

| Plenum (height) | 800mm |

| Extraction | Through exhaust plenum chambers on both sides |

| Extraction area | 24m2 |

| Entrance door | 5000x4500mm (WxH), electric door, 2 sets |

| Service door | 800x2000mm(WxH), 4 sets |

| Walls | 60mm rock wool walls |

| Ceiling lights (LED) | 22 sets, each 4 X 18W, 1,584W total |

| Sidewall lights (LED) | 24 sets, each 4 X 18W, 1,728W total |

| Brightness | >1,000LUX |

| Filters | Bag filter, high efficiency ceiling filter, filter at exhaust plenum chambers, exhaust filter |

| Intake/Exhaust unit | Direct-type turbine fan,2x11KW, SIEMENS motor |

| Air volume | 2*35,000m3/h |

| Empty loaded air speed | 0.20m/s |

| Heats | 2*315kw heat exchanger, RIELLO gas burner RS5D*2 |

| Maximum working temperature | 80ºC |

| Controls | CE standard control box |

| Inverter | SCHNEIDER inverter |

| Conveyor chain | Floor conveyor chain, 3 carriages Loading capacity≥5 ton |

| Rated power | 50KW |

3.DETAILS

CABIN STRUCTURE

- The cabin strength is reinforced by gantry structure made of 80*80 square tubes.

- Airflow: side downdraft airflow, air extracted from side exhaust plenum chambers

ELECTRIC PLATE ROLL-UP DOOR

- Door filled with polyurethane foam, with reinforced ribs;

- With observation window;

- Anticrash protection device and anti-sagging device.

Air handling unit

- Direct-drive fan unit, fully comply with CE standard

- Air volume: 2*35,000m3/h

OPTION

- Bigger air volume fan unit as option (belt-drive fan units)

- Direct gas fired heating system

Control

Floor conveyor

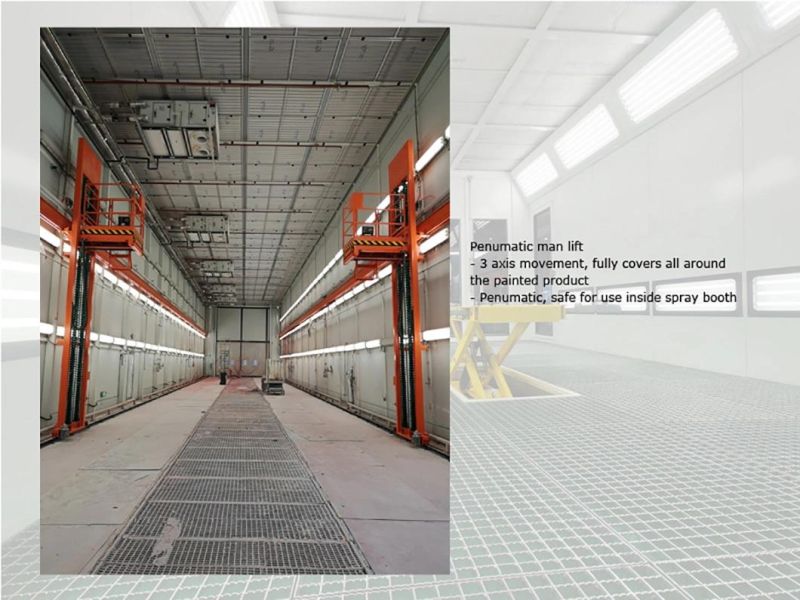

Man lift

Man lifts are fixed to booth walls and move from one end to the other as well as up and down and in and out. With the critical man lift in your paint booths, you will work smarter and safer, and no need for scaffolding or electric lifts to try and maneuver around the inside of your booth.

FAQQ: For my products, the floor conveyor is not suitable. Can you supply overhead conveying system?A: That's okay. Send us the inquiry, we will get back to you with the solution then.

Q: Can you supply paint booth which suits the conveyance of the products to the inside of the booth by using overhead crane?A: Yes. We designed, manufactured and supplied such paint booth before. We are confident to supply the perfect solution for you. Contact us and we will show you some photos of the similar design for your reference.

Q: Can you integrate man lift to the paint booth?A: That's okay. Pneumatic man lifts are available. With the man lifts added on both sides, the recommended minimum internal width of the booth is 5500mm.

Q: Do you supply powder coating and drying booth?A: We do not manufacture and supply powder coating equipment.

We are in the line of spray booth business. Welcome to send your inquires about spray booths.

Q: I also need a paint mixing room.A: Okay. We think we should make the mixing room just next to the spray booth, with a service door shared by both mixing room and paint booth. Anyway, show us the layout of the equipment. So we can work out the right solution for your reference.

Q: Please follow the supplied layout to arrange the equipment in the workshop and advise if there is any problem with the supplied layout.A: Certainly. We have in-house design team to check the layout and work out the ideal solution for you.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23