High Torque Backstop Clutch Rsci220II-M with Sprag Type From China

Xinxiang Heguang Industry Co., Ltd, China / 2022-06-08

- Product Name:High Torque Backstop Clutch Rsci220II-M with Sprag

- Material:Bearing Steel

- Type:Sprag

- Bore Size:220mm

- Outside Size:490mm

- Torque (Nm):36000

=== Base Info ===

- Model NO.:RSCI220II-M

- Weight (Kg):249

- OEM:Accept

- Application:Air Blower ; Water Pump; Gearbox

- Market:Global

- Transport Package:Industry Packing

- Specification:bearing steel

- Trademark:SUMA

- Origin:Changzhou, Jiangsu, China

- HS Code:84836000

- Production Capacity:1000PCS,Month

=== Description ===

| Type | Size | Torque | Speeds | | No. | | Weight |

RSCI | dH7 | TKN | nmax | nimin | nimax | D | D1h6 | D2H7 | D3 | D4 | z | L | I | I1 | I4 | f×45° | dmin | m | tmin | I2 | I3 | RSCI | F8 |

| mm | Nm | min-1 | min-1 | min-1 | mm | mm | mm | mm | | | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | kg | kg |

| 20 | 212 | 315 | 750 | 15000 | 90 | 36 | 66 | 78 | M6 | 6 | 35 | 35 | 25 | 0 | 0.8 | 52 | 5 | 1 | 8 | 16 | 1.5 | 0.3 |

| 25 | 319 | 300 | 725 | 14000 | 95 | 40 | 70 | 82 | M6 | 6 | 35 | 35 | 25 | 0 | 1 | 56 | 5 | 1 | 8 | 16 | 1.6 | 0.4 |

| 30 | 375 | 290 | 700 | 11000 | 100 | 45 | 75 | 87 | M6 | 6 | 35 | 35 | 25 | 0 | 1.5 | 62 | 5 | 1 | 8 | 16 | 1.8 | 0.4 |

| 35 | 550 | 280 | 670 | 11000 | 110 | 50 | 80 | 96 | M6 | 8 | 35 | 35 | 25 | 0 | 1.5 | 66 | 5 | 1 | 8 | 16 | 2.1 | 0.5 |

| 40 | 800 | 260 | 630 | 8000 | 125 | 60 | 90 | 108 | M8 | 8 | 35 | 35 | 25 | 0 | 1.5 | 76 | 5 | 1 | 10 | 21 | 2.7 | 0.7 |

| 45 | 912 | 255 | 610 | 7000 | 130 | 65 | 95 | 112 | M8 | 8 | 35 | 35 | 25 | 0 | 1.5 | 82 | 5 | 1 | 10 | 21 | 2.9 | 0.9 |

| 50 | 1400 | 235 | 560 | 6000 | 150 | 80 | 110 | 132 | M8 | 8 | 40 | 40 | 25 | 0 | 1.5 | 100 | 7.5 | 1 | 10 | 21 | 4.3 | 1 |

| 60 | 2350 | 210 | 510 | 6000 | 175 | 85 | 125 | 155 | M10 | 8 | 60 | 50 | 36 | 5 | 2 | 110 | 12 | 2 | 12 | 35 | 6.5 | 1.8 |

| 70 | 3050 | 195 | 470 | 4000 | 190 | 100 | 140 | 165 | M10 | 12 | 60 | 50 | 36 | 5 | 2 | 120 | 12 | 2 | 12 | 35 | 8.6 | 1.9 |

| 80 | 4500 | 180 | 440 | 4000 | 210 | 120 | 160 | 185 | M10 | 12 | 70 | 60 | 36 | 5 | 2 | 140 | 17 | 3 | 12 | 35 | 12.5 | 2.6 |

| 80M | 5800 | 155 | 375 | 4000 | 210 | 120 | 160 | 185 | M10 | 12 | 70 | 60 | 46 | 5 | 2 | 140 | 12 | 2 | 12 | 35 | 13.1 | 2.6 |

| 90 | 5600 | 170 | 410 | 3000 | 230 | 140 | 180 | 206 | M12 | 12 | 80 | 70 | 36 | 5 | 2.5 | 165 | 22 | 3 | 12 | 35 | 17.4 | 3 |

| 90M | 8700 | 145 | 350 | 3000 | 245 | 140 | 180 | 206 | M12 | 12 | 80 | 70 | 46 | 5 | 2.5 | 160 | 17 | 2 | 12 | 35 | 18.3 | 3 |

| 100 | 10500 | 145 | 355 | 3000 | 290 | 140 | 210 | 258 | M16 | 12 | 90 | 80 | 52.6 | 5 | 2.5 | 180 | 18.6 | 3 | 15 | 37 | 28 | 5 |

| 100M | 16000 | 140 | 340 | 2400 | 290 | 170 | 210 | 258 | M16 | 12 | 90 | 80 | 63 | 5 | 2.5 | 200 | 13.5 | 2 | 12 | 35 | 30 | 5 |

| 130 | 15750 | 135 | 330 | 2400 | 322 | 170 | 240 | 278 | M16 | 12 | 90 | 80 | 52.6 | 5 | 3 | 210 | 18.6 | 3 | 15 | 37 | 35 | 6 |

Speeds

| No. | | Weight | | RSCI | dH7 | TKN | nmax | nimin | nimax | D | D1h6 | D2H7 | D3 | D4 | z | L | I | I1 | I4 | f×45° | dmin | m | tmin |

| mm | Nm | min-1 | min-1 | min-1 | mm | mm | mm | mm | | | mm | mm | mm | mm | mm | mm | mm | mm | kg |

| 180 | 31500 | 115 | 285 | 1300 | 412 | 240 | 310 | 360 | M20 | 12 | 90 | 80 | 53 | 5 | 3.5 | 280 | 18.6 | 3 | 59 |

| 180 M | 50000 | 90 | 220 | 1300 | 422 | 240 | 310 | 370 | M20 | 18 | 120 | 120 | 83 | 0 | 4 | 280 | 18.5 | 2 | 92 |

| 180 II | 63000 | 115 | 285 | 1300 | 412 | 240 | 310 | 360 | M20 | 24 | 160 | 160 | 118 | 0 | 3.5 | 280 | 21 | 3 | 116 |

| 180 II-M | 100000 | 90 | 220 | 1300 | 425 | 240 | 310 | 370 | M24 | 24 | 240 | 240 | 176 | 0 | 4 | 280 | 32 | 3 | 190 |

| 220 | 42500 | 110 | 265 | 1100 | 470 | 290 | 360 | 410 | M20 | 16 | 105 | 80 | 60 | 12.5 | 4 | 330 | 19.5 | 3 | 90 |

| 220 M | 68000 | 85 | 205 | 1100 | 480 | 290 | 360 | 410 | M24 | 16 | 120 | 120 | 83 | 0 | 4 | 330 | 18.5 | 2 | 109 |

| 220 II | 85000 | 110 | 265 | 1100 | 480 | 290 | 360 | 430 | M24 | 18 | 160 | 160 | 130 | 0 | 4 | 330 | 15 | 3 | 159 |

| 220 II-M | 136000 | 85 | 205 | 1100 | 490 | 290 | 360 | 425 | M30 | 20 | 240 | 240 | 176 | 0 | 4 | 330 | 32 | 2 | 249 |

| 240 | 52000 | 105 | 250 | 1100 | 500 | 320 | 390 | 440 | M20 | 16 | 105 | 90 | 60 | 7.5 | 4 | 360 | 15 | 2 | 95 |

| 240 M | 83000 | 80 | 195 | 1100 | 520 | 320 | 390 | 440 | M24 | 16 | 120 | 120 | 83 | 0 | 4 | 360 | 18.5 | 2 | 137 |

| 240 II | 104000 | 105 | 250 | 1100 | 520 | 320 | 390 | 440 | M24 | 24 | 180 | 180 | 132 | 0 | 4 | 360 | 24 | 2 | 191 |

| 240 II-M | 166000 | 80 | 195 | 1100 | 530 | 320 | 390 | 455 | M30 | 24 | 240 | 240 | 181 | 0 | 4 | 360 | 32 | 2 | 250 |

| 260 | 65000 | 100 | 240 | 1000 | 550 | 360 | 430 | 500 | M24 | 16 | 105 | 105 | 60 | 0 | 4 | 400 | 22.5 | 2 | 130 |

| 260 M | 100000 | 75 | 185 | 1000 | 580 | 360 | 430 | 500 | M24 | 24 | 125 | 125 | 83 | 0 | 4 | 400 | 21 | 2 | 183 |

| 260 II | 130000 | 100 | 240 | 1000 | 580 | 360 | 430 | 500 | M24 | 24 | 210 | 210 | 132 | 0 | 4 | 400 | 39 | 2 | 262 |

| 260 II-M | 200000 | 75 | 185 | 1000 | 580 | 360 | 430 | 500 | M30 | 24 | 250 | 250 | 176 | 0 | 4 | 400 | 37 | 2 | 369 |

| 300 | 78000 | 90 | 225 | 1000 | 630 | 410 | 480 | 560 | M24 | 24 | 105 | 105 | 60 | 0 | 4 | 460 | 22.5 | 3 | 174 |

| 300 M | 125000 | 70 | 175 | 1000 | 630 | 410 | 480 | 560 | M24 | 24 | 125 | 125 | 83 | 0 | 4 | 460 | 21 | 3 | 210 |

| 300 II | 156000 | 90 | 225 | 1000 | 630 | 410 | 480 | 560 | M24 | 24 | 210 | 210 | 134 | 0 | 4 | 460 | 38 | 3 | 351 |

| 300 II-M | 250000 | 70 | 175 | 1000 | 630 | 410 | 480 | 560 | M30 | 24 | 250 | 250 | 182.6 | 0 | 4 | 460 | 33.7 | 3 | 457 |

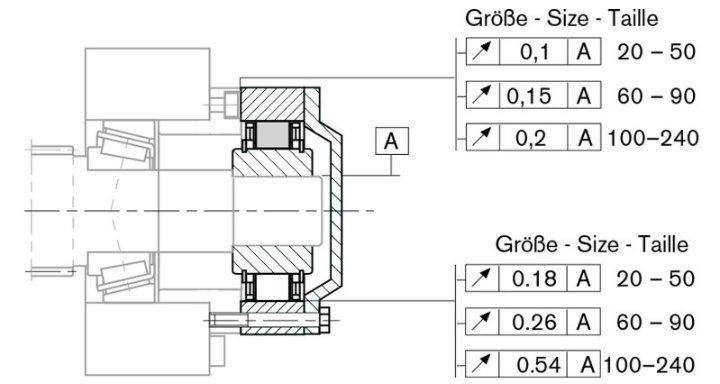

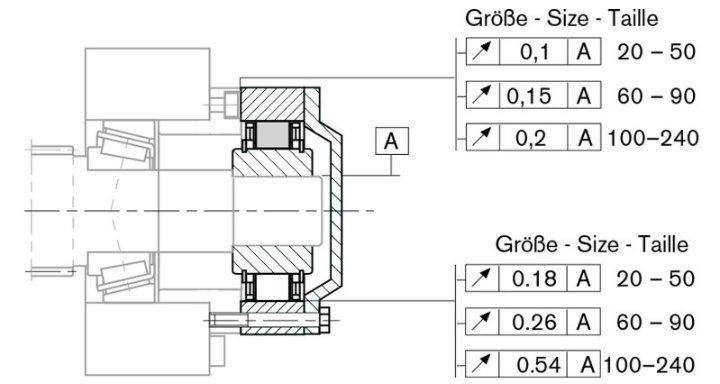

Mounting Example

Application

Application