TANN All Series H/HE/HS/HA Adapter Sleeves

Yuyao Comon Foreign Trade Co., Ltd. / 2022-06-08

- Customized:Customized

- Certification:ISO

- Standard Parts:Yes

- Universal:Yes

- Material:Stainless Steel

- Cold Heading:National Cold Header From USA

=== Base Info ===

- Model NO.:All Series H,HE,HS,HA

- Heat Treatment:Under The Requirements of Cqi-9

- Hard Grinding:Auto Integrated Production Lines

- Honing:100% on-Line Eddy Current Check After Honing

- Transport Package:Industrial Packing

- Trademark:TANN or Be Customized

- Origin:China

- HS Code:8482990000

=== Description ===

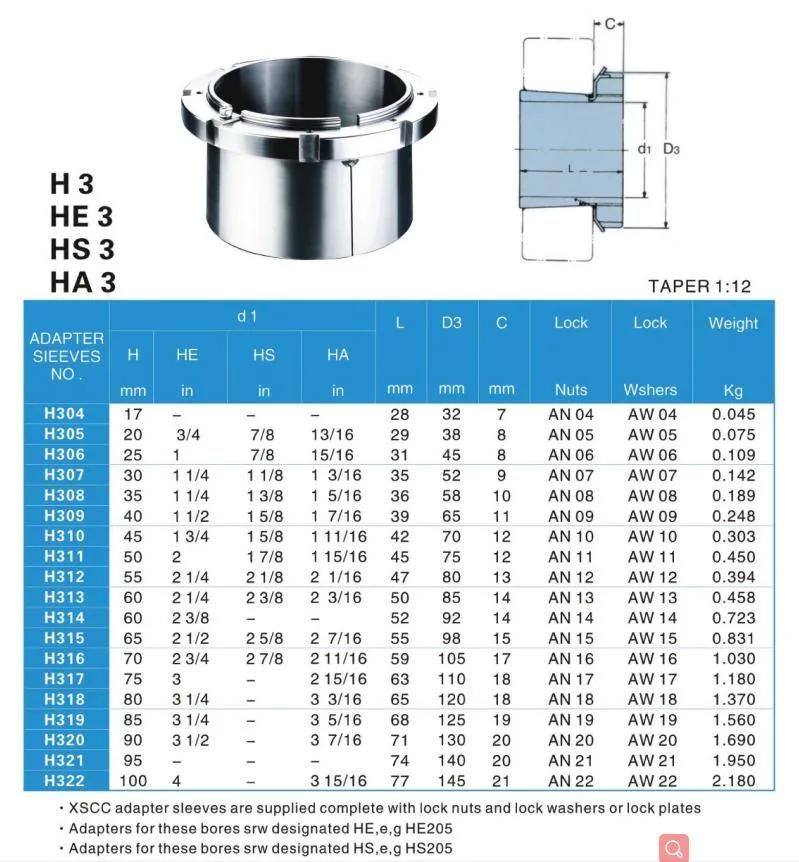

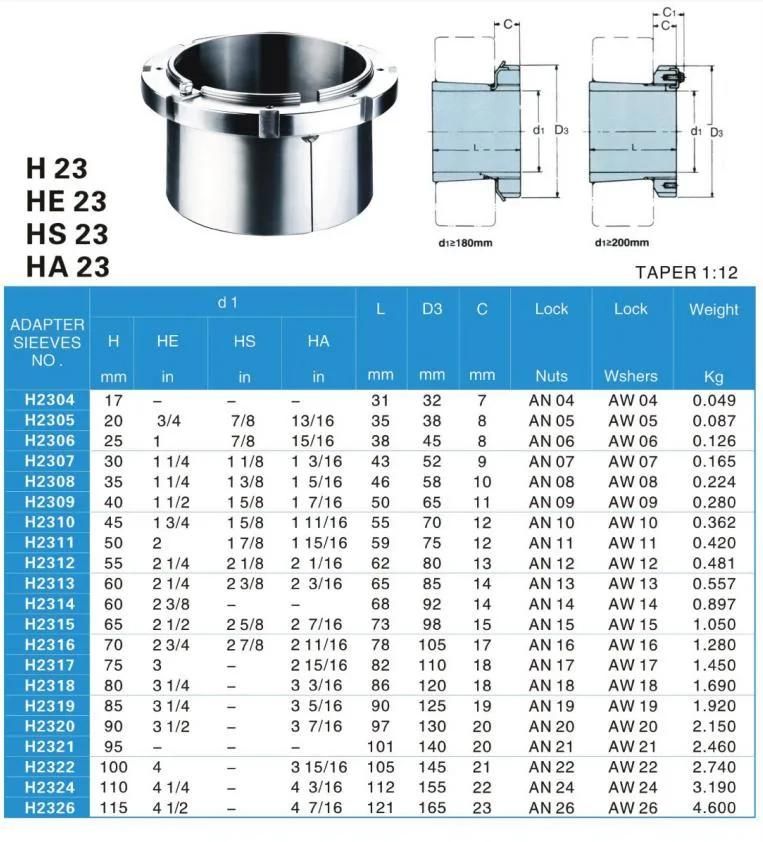

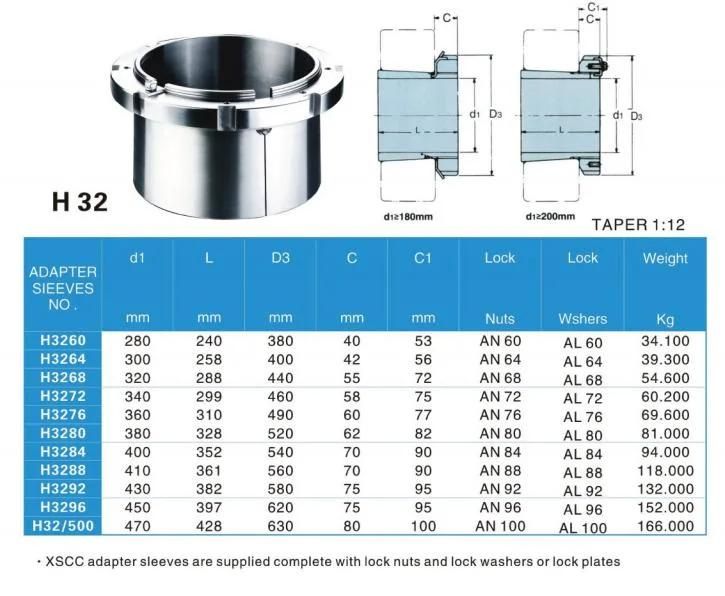

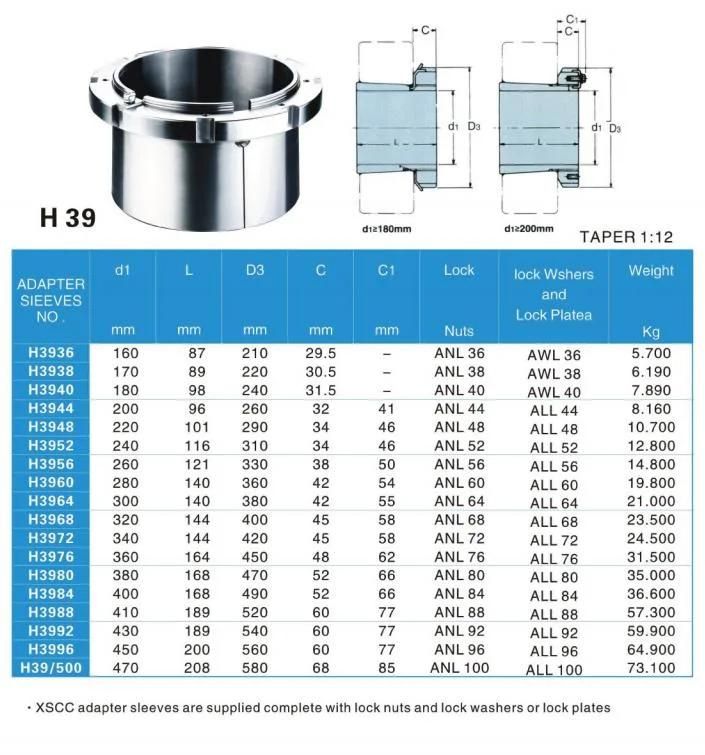

Adapter Sleeves

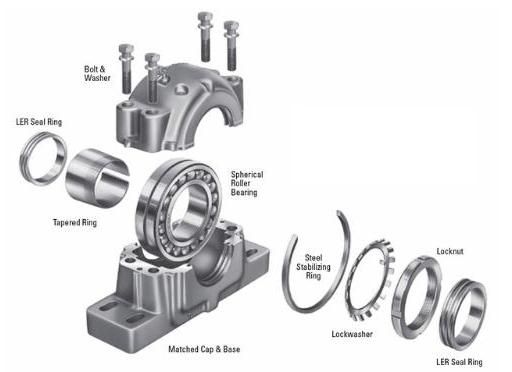

Adapter sleeves are the most commonly used components for locating bearings with a tapered bore onto a cylindrical seat as they can be used on:

-Plain shafts

-Stepped shafts

They are easy to install and require no additional location on the shaft:

-When used on plain shafts, the bearing can be located at any position on the shaft.

-When used on stepped shafts together with an L-shaped spacer ring, the bearing can be accurately positioned axially, thereby facilitating bearing mounting and dismounting.

PRODUCT HIGHLIGHTS

PRODUCT HIGHLIGHTS- Includes Sleeve, Nut & Washer

- Ensures a secure fit to straight and stepped shafts

- Split tapered and threaded sleeves combined with a retaining nut and lock washer

- Used to mount a tapered bore bearing to a straight shaft

- Provides tight accurate seating

Adapter Sleeves

Granville bearing manufacturer in the production of electric motor grade deep groove ball bearings, the company is committed to developing all kinds of precision radial ball bearings with an inner diameter of 2mm-100mm.

The factory covers an area of 58000 square meters, the company has advanced assembly lines and a perfect quality testing center. After more than ten years of management and innovation, with more than 120 automatic production lines, various kinds of testing, and inspection instruments, with the annual production capacity of 160 million sets of reliable high precision quality bearings.

The comprehensive application of automation production lines is a premise to ensure product's stable quality, what's more, it is a mark that the enterprises improve to digital management modern high-tech manufacturer.

Seiko quality, the pursuit of excellence: the control and improvement of quality is the constant pursuit of Granville, in strict accordance with the system of the provisions of the quality of each process.

We strictly follow the core of quality management process control:

APQP: product quality advance planning

SPC: Statistical process control

MSA: Measurement system analysis

FMEA: Analysis of potential failure modes and consequences

PPAP: Production part approval procedure

In the factory testing laboratories, various bearing parts are examined in detail. The factory has its own professional bearing life tester, after bearing life and durability test, our bearings have the advantages of long service life, and high durability. We are keeping an introduction of the latest measurement and testing equipment. Quality procedures are based on extensive, repeatedly carried out product tests - both before inclusion in the range and after.

We manufacturing:

The Granville manufacturer takes her every effort in purchasing the most advanced bearing process equipment, automatic facilities are widely used in the factory and we keep investing to improve more.

Levels Applications Materials

We manufacture GIL bearings, the advantage in manufacturing electric motor quality deep groove ball bearings up to ABEC-3, Z3-V3, ABEC-5 Z4-V4 level; A reliable production resource of high-quality repair parts for the aftermarket operations of automotive and light truck manufacturers worldwide, over 1000 kits includes hub assemblies and three generations of wheel bearing designs; Granville foundry makes an extensive and full line of mounted bearing units and housings in industry-standard and custom configurations. Casting iron, ductile iron, stainless steel, and plastic materials are available.

Partnerships Reliable Supply-Chain:

Based on our experienced team and strict, effective supply chain management, Granville products deliver premium quality, and performance our customers have relied on for years. From a full range of bearings, mounted bearing units, power transmission products, and related markets around the world, we provide the industry's most comprehensive range of qualified products available today. Advantage Manufacturing Processesand Quality Control:

Advantage Manufacturing Processesand Quality Control:01 Heat Treatment

02 Centerless Grinding Machine 11200 (most advanced)

03 Automatic Production Lines for Raceway

04 Automatic Production Lines for Raceway

05 Ultrasonic Cleaning of Rings

06 Automatic Assembly

07 Ultrasonic Cleaning of Bearings

08 Automatic Greasing, Seals Pressing

09 Measurement of Bearing Vibration (Acceleration)

10 Measurement of Bearing Vibration (Speed)

11 Laser Marking

12 Automatic PackingQ&A

*Could you make a brief introduction to your all series of products?

Yes, we stock and sell factory-warrantied mechanical, electrical, and fluid-driven equipment such as bearings, belts, drives, motors, gears, couplings, clutches and brakes, linear motion, and hydraulics and pneumatics.

*How about your sales group?

At Granville, we understand a competent team makes your job easier, so we have established a group of employees who represent our resourcefulness and commitment to working hard to make sure your unique challenges are handled right the first time.

*What's your solutions for maximizing customers' benefits?

Our goal is to have your stock requirements on-hand when you need them. Through our storeroom surveys, in-depth communication, and usage analysis, we can reduce your organization's inventory cost, supply room costs, and turn-around time.

*What's your shipping document and documents of payment?

Our usual practice is FOB Shanghai & T/T, and we could adjust them for your requirements.

*What's the most convenient way to get your free quotation?

Please contact Stacy with your requirements (or Copy the contents of the table and fill in it with your information)

| RFQ for Free |

| Company Name: |

| Name: Mr./Mrs./Miss |

| Email: |

| Bearing No. : |

| Quantity: |

| More Details: |

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23