Single Row Deep Groove Ball Bearing 6203 with Low Noise

Shanghai Unico Industry Co., Limited / 2022-06-08

- Contact Angle:Customized

- Aligning:Customized

- Separated:Customized

- Rows Number:Customized

- Load Direction:Thrust Bearing

- Material:Bearing Steel

=== Base Info ===

- Model NO.:NDPJ-ZC-4

- Material Type:Steel Gcr 15

- Dimension:Customized

- Composition:Two Rings, Rolling Elements and a Cage

- Seal Type:Rubber or Iron

- Grease Type:SRL or Customized

- Certifiacate:CCC

- Condition:New

- Vibration Grade:Customized

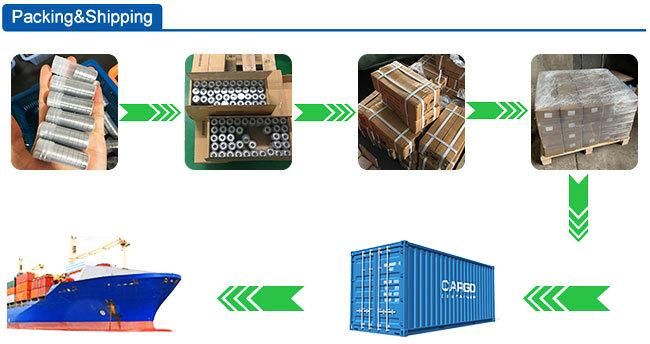

- Transport Package:Pallet

- Specification:customized

- Trademark:NIDE

- Origin:China

- HS Code:8482109000

- Production Capacity:1, 000, 000PCS,Year

=== Description ===

Frequency Bands

Low Band

Medium Band

High Band

Frequency Range

50-300HZ

300-1800HZ

1800-10000HZ

Nide team could manufacture ball bearing as per customer's drawing and samples. If customer only has samples, we could also design drawing for our customer. We also provide customized service.

Furthermore, the machine electronically translates these signals by a heterodyning process, making them audible, so that inspectors can hear these sounds from the machine speaker and see them as intensity increments on a meter. By this way, testing results also enable the determination of the likely cause of the bearing irregularity. NIDE is making 100% such noise and vibration testing before every single bearing leaves the factory. Also, NIDE has recently significantly improved design of deep groove ball bearings, to further reduce noise and vibration levels.

Customers need to pay attention when coming across the following conditions

Type1: Self-Generated Vibration

Description: Vibration generated from the bearing itself when it is in the rotating condition

Cause: Variations of circular form in the bearing balls and raceway

Countermeasures: Can not be avoided, but could reduce the vibration level by selecting the proper clearance due to the application.

Type2: Vibration Arising from Exposure to External

Description: Disturbed noises occur with the performance degrades of bearings in modes known as wear oxidation or corrosion fretting.

Cause: The contaminated surrounding environment affects bearing. Loaded bearing operate without sufficient lubrication.

Countermeasures: These conditions can be relieved by properly designed isolation supports and adequate lubrication.

Type3: Vibration from Mis-alignment

Description: Not well-aligned bearings make noise when they are rotating.

Cause: Bearings are not well aligned on the shafts or houses during installation. The shafts and houses are not accurate.

Countermeasures: Good alignment methods and special alignment tools to reduce vibration. Applying hight accuracy shafts and houses.

Type4: Local Damage Vibration

Description: The small damaged sections on the raceways and rolling elements generate a specific vibration frequency.

Cause: Mishandling or incorrect mounting.

Countermeasures: Applying correct mounting methods and mechanical tools such as fitting tools, applying induction heaters with time control and pre-set temperature mode.

Information needed for ball bearing inquiry

It will be better if customer could send us detailed drawing including below information.

1.Ball bearing model number

2. Ball bearing dimension

3. Ball bearing application

4. Required quantity

5. Other technical requirement.

Q: Are you trading company or manufacturer ?

A:We are a manufacturer

Q: Do you provide samples ? is it free or extra ?

A:There are many kinds of products in our company. Samples should be sent according to the types of products and negotiated with customers.

Q. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q: How do you make our business long-term and good relationship?

1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23