Downdraft Booth Auto Maintenance Paint Booth for Car

Dongguan Sowo Packaging Materials Co., Ltd. / 2022-06-23

- Type:Spray Booth

- Certification:CCC, CE

- Substrate:Steel & Aluminum

- Brand:Yokistar

- Coating:Painting & Powder Coating

- Airflow Direction:Full Downdraft Airflow Way

=== Base Info ===

- Model NO.:Bioble-PB

- Heating Mode:Diesel

- Paint Mist Treatment:Dry-type

- Condition:New

- Ventilation:Full Downdraft Airflow Way

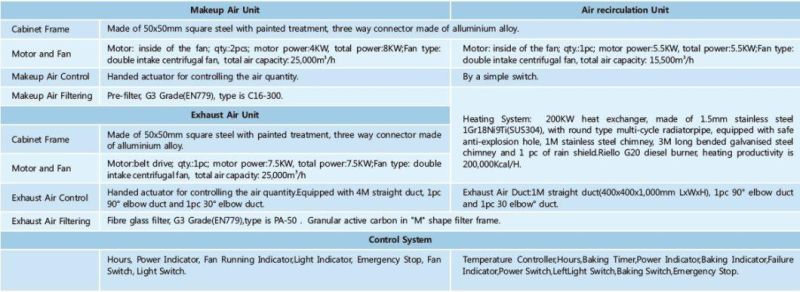

- Air Intake (Painting Booth):2*4kw Inner Motor Double-Intake Centrifuagal Fan

- Air Exhaust (Panting Booth):1*7.5kw Belt-Drive Type Motor Centrifugal Fan

- Air Recirculation (Baking Booth):1*5.5kw Inner Motor Double-Intake Centrifuagal Fan

- Heating (Baking Booth):1 Unit Riello G20 Diesel Burner

- Voltage:1X220V, 3X380V, Your Special Voltages Are Accepted

- Optional Colour:White, Blue, Orange and Red

- Port:Huangpu Port or by Your Order

- Main Product:Spray Booth, Prep Station, Infrared Curing System

- Color:Optional

- Transport Package:Bubble Film Packing for Sea Transportation in Bulk

- Specification:40′GP can load 1 set, 40′HQ can load 2 sets.

- Trademark:YOKISTAR

- Origin:Guangzhou, China

- HS Code:84198990

- Production Capacity:120units,Month

=== Description ===

Basic Info.

Model NO. Bioble-PB Heating Mode Diesel Paint Mist Treatment Dry-type Condition New Ventilation Full Downdraft Airflow Way Air Intake (Painting Booth) 2*4kw Inner Motor Double-Intake Centrifuagal Fan Air Exhaust (Panting Booth) 1*7.5kw Belt-Drive Type Motor Centrifugal Fan Air Recirculation (Baking Booth) 1*5.5kw Inner Motor Double-Intake Centrifuagal Fan Heating (Baking Booth) 1 Unit Riello G20 Diesel Burner Voltage 1X220V, 3X380V, Your Special Voltages Are Accepted Optional Colour White, Blue, Orange and Red Port Huangpu Port or by Your Order Main Product Spray Booth, Prep Station, Infrared Curing System Color Optional Transport Package Bubble Film Packing for Sea Transportation in Bulk Specification 40′GP can load 1 set, 40′HQ can load 2 sets. Trademark YOKISTAR Origin Guangzhou, China HS Code 84198990 Production Capacity 120units/MonthProduct Description

Product details:**Model:Bioble-PB(paint &baking room)

**Outside dimention:

Painting Booth 8650*4000*3400mm (L*W*H)

Baking Booth 8200*4000*3100mm (L*W*H)

**It fits for auto cars spraying and painting,which indicates also suitable for 4S shop and end-user.

**Custom paint booth is the key point for YOKSTAR,professional technical team and passionate sales are always ready for you.

**CE certificate approval.

Introduction

Spray booth comes out as it is seasoned with spraying for whole surface of modern automobiles, part repair and baking which can provide operation room of cleanness, sanitation for above tasks. The whole set equipment has the function of ventilation, air purge, drying, disposing exhaust gas and so on which meets basic requests of auto surface disposal. The equipment is made up of room body, lighting unit, intake and exhaust air system, heating system, air purge system, exhaust gas disposal system and control system.

Spray Booth Conveying and Storage

As spray booths are in big size, they're conveyed in bulk while loading and unloading. The parts in frame should be loaded and unloaded by fork vehicles while the small parts are conveyed by manpower. Be noticed to make sure that the parts are not damaged and dilapidated in the loading and unloading process.

The finished parts of spray booth are usually stored in the finished products warehouse, and marked on the outside packages for checking before delivery. After being sent to the destination, all the parts should not be put in the open air but in store house to prevent from rusting and oxidized by the moisture.

Working principle

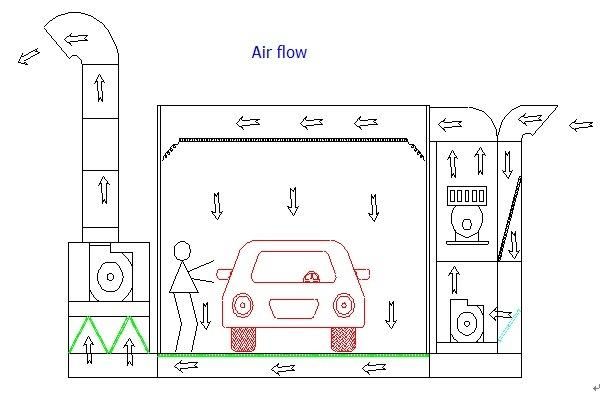

The air flow:

Fresh air →pre-filter →intake air fan→ heating generator →plenum →ceiling filter →working area of the spray booth →the first exhaust air filter →the second exhaust air filter →exhaust air fan →exhaust air duct →atmosphere

See the normal spraying principle figure for details:

*Maintenance

Spray booth is a kind of special equipment which includes machinery, electrical parts, filter materials, airproof parts and many other parts. So in the daily using please pay more attention of the repair and maintenance. There are several aspects as below:

Maintenance of filter system

The filter system is an important part of spray booth, usually it includes prep-filter, ceiling filter and fiberglass filter.

- Prep-filter is a used for filtering fresh air, normally it should be replaced after 100 working hours.

- Ceiling filter is used for second-filter of air, normally it should be replaced every 400 working hours.

- Fibreglass filter is used to collect solvent fumes of exhaust air. There're 2 fiberglass filter of the booth. Generally it should be replaced every 80-120 working hours.

Maintenance of airproof parts

In order to make sure the airproof capacity of the booth, airproof parts are needed a lot. As the air produced by working booth is caustic, and airproof parts are often made of rubber materials which are easily suffered, so timely renewing the airproof parts are indeed to ensure a high quality.

Maintenance of electrical parts

As "brain" of the booth, control system directly conducts all kinds of operation for the booth. So it is extremely important to keep a good stableness of all electrical parts. During operating time, periodic checking of all electric parts is recommended in order to ensure correct and precise operation.

Maintenance of gearing parts

Gearing parts are mainly composed of straps between motors and fans. As they're used frequently, straps would become loose and worn after a period of enlistment. So adjust the belts according to working condition and replace them if necessary, so the working effect of fans can reach the best. Furthermore, there are oil-holes at the two ends of the axletrees of fans, periodically lubricate the above oil-holes to keep a smoothly running.

Maintenance of other parts

So as to ensure the performance of spray booth, daily maintenances of other parts are also needed. It mainly includes cleaning the booth, checking tight-and-loose of connections, checking the working environments outside and so on, all which have been done well to prevent from unseen accidents.

NOTICE: The maintenance work should be done by the person specially assigned for a job,and the following should be done in the maintenance process:

a. Any sundries can NOT be put in the booth.

b. Close the power supply of the booth, and set warning sign at the main power supply.

c. All the replaced filters should be disposed in a special way, they can not be disposed as the normal garbage.

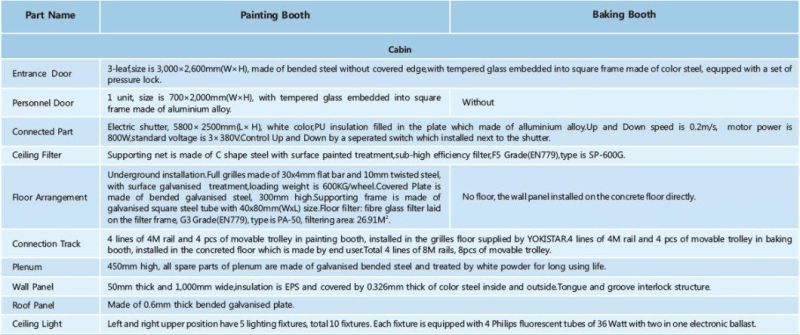

Specification List of Auto Painting Baking Booth Bioble-PB

Warranty

The goods are guaranteed for 24 months from the date of receipt, but the filters and lamps are not guaranteed. It cannot be applied for damages caused by negligence of operations or mishandling of the machine.

YOKISTAR ProductsHigh quality and advanced technology are applied in YOKISTAR product ranges, involving automotive spray booth, bus and truck spray booth, prep station, mixing room, bench spray booth, open face spray booth and infrared curing lamp.

Contact info:

Mobile:86-18602063403

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23