Original High Precision Planetary Gearbox Reducer for Automation Equipment

Heavybao Commercial Kitchenware Co., Ltd. / 2022-06-27

- Application:Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car

- Hardness:Hardened Tooth Surface

- Installation:Vertical Type

- Layout:Coaxial

- Gear Shape:Bevel Gear

- Step:Single-Step

=== Base Info ===

- Model NO.:EROTOG840

- Type:Planetary Gear Reducer

- Transport Package:Carton Box

- Specification:size 60

- Trademark:Newgear

- Origin:China

- HS Code:8483402090

- Production Capacity:300, 000 Set Per Year

=== Description ===

Basic Info.

Model NO. EROTOG840 Type Planetary Gear Reducer Transport Package Carton Box Specification size 60 Trademark Newgear Origin China HS Code 8483402090 Production Capacity 300, 000 Set Per YearProduct Description

Product Description

PD series High Precision Planetary Gear Reducer For Automation Equipment

Newgear Series Precision Planetary reducer gearbox for Industrial Robot and Automatic Arm

This helical planetary gearbox is used for servo motor and related device which need to reduce speed or enlarge torque! Newgear helical planetary gearboxes external diameter from 60 to 220, gear ratio from 3 to 100! It has high precision and are widely used with servo motor such like Panasonnic,Fuji, Mitsubishi, Omran,Delta, Teco.

Description:

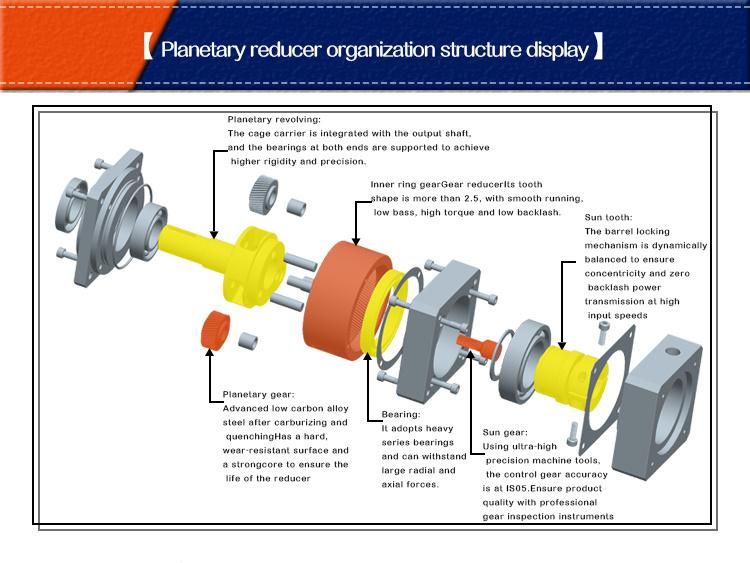

(1).The output shaft is made of large size,large span double bearing design,output shaft and planetary arm bracket as a whole.The input shaft is placed directly on the planet arm bracket to ensure that the reducer has high operating accuracy and maximum torsional rigidity.

(2).Shell and the inner ring gear used integrated design,quenching and tempering after the processing of the teeth so that it can achieve high torque,high precision,high wear resistance.Moreover surface nickel-plated anti-rust treatment,so that its corrosion resistance greatly enhanced.

(3).The planetary gear transmission employs full needle roller without retainer to increase the contact surface,which greatly upgrades structural rigidity and service life.

(4).The gear is made of Japanese imported material.After the metal cutting process,the vacuum carburizing heat treatment to 58-62HRC. And then by the hobbing,Get the best tooth shape,tooth direction,to ensure that the gear of high precision and good impact toughness.

(5).Input shaft and sun gear integrated structure,in order to improve the operation accuracy of the reducer.

Characteristic:

(1) Low Noise:The use of helical gear design,to achieve a smooth,quite operation of the reducer.

(2) High Precision:Backlash is 3 arcmin or less,accurate positioning.

(3) High Rigidity,High Torque:The output shaft used large size,large span double support bearing design,which improves the rigidity and torque of the reducer.

(4) High Efficiency:1-stage up to 95% or more,2-stage up to 92% or more.

(5) Maintenance-Free:Low grease wear,can be lifetime lubrication.

(6) Sealing Effect is Good:Lubricating grease with high viscosity,not easy to separate the characteristics,ip65 protection class to ensure that no grease leakage.

(7) Installation Unrestrained:Can be installed arbitrarily.

(8) Wide Applicability:Applicable to any type of servo motor.

(9) An organic [integral] whole output axis.

Quality inspection procedure:

We have 20 QC/QA workers.10 strict QC processes including incoming materials QC, IPQC 10 Ageing test QC100% products will go through a 24-hours ageing test QC)before shipping.

Package;

Or we can make the neutral package as customer's request.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23