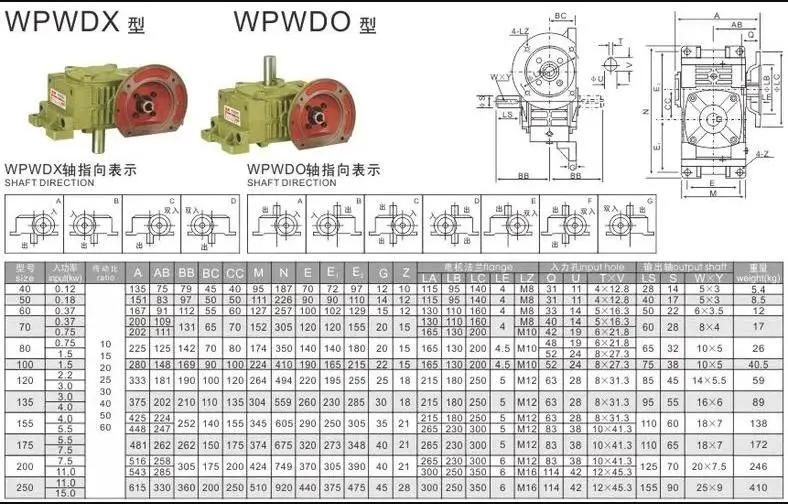

Eed Transmission Single Wpwdx/Wpwdo Series Gearbox Size 155 Input 5.5kw

Qingdao Sy Packaging Ltd / 2022-06-27

- Application:Motor, Machinery, Agricultural Machinery

- Hardness:Hardened Tooth Surface

- Installation:Vertical Type

- Layout:Coaxial

- Gear Shape:Conical - Cylindrical Gear

- Step:Single-Step

=== Base Info ===

- Type:Worm Reducer

- Manufacturing Method:Cut Gear

- Toothed Portion Shape:Spur Gear

- Size:40-250

- Ratio:1,10-1,60

- Weight:4-376kg

- Transport Package:According to The Customer Request

- Specification:Standard

- Trademark:EED

- Origin:China

- HS Code:8483409000

- Production Capacity:800-1500PCS ,Month

=== Description ===

Basic Info.

Type Worm Reducer Manufacturing Method Cut Gear Toothed Portion Shape Spur Gear Size 40-250 Ratio 1/10-1/60 Weight 4-376kg Transport Package According to The Customer Request Specification Standard Trademark EED Origin China HS Code 8483409000 Production Capacity 800-1500PCS /MonthProduct Description

Overview-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Quick Details

Gearing Arrangement: Worm Brand Name: EED

Input Speed: 1400 rpm Certification: CE, ROHS, ISO9000

Rated Power: 3 ~ 4KW Output Torque: 2.8-2430N.M

Color: Blue/Silver or on request Origin: Zhejiang, China (Mainland)

Warranty: 1 Year Ratio:1/10.1/15,1/20,1/25,1/30,1/40,1/50,1/60

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Supply Ability

Supply Ability: 20000 Piece/Pieces per Month

Extra Service: OEM is welcome

QC System: ISO9001:2015

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Packaging & Delivery

Package: Wooden box/Paper carton

Port: Ningbo/Shanghai or on request

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Widely used in turbines, shaft liners and axletrees, good resistance to wearing, with high precision in

dimensions, lower noise, advanced centric running castings

2. Without vent and highly precision

3. The whole structure is compact and the weight is larger

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Notice of installation

1 .Thebase-plate must be plane and stoutness, and the base-plate must be screwed downand shockproof.

2. Theconnecting shaft of prime mover, reducer and operation device must be coaxialinstallation.

3 .Thediameter tolerance zone of input and output shaft is H6, the holes of fittings(such as couplings, belt-

pulley, sprocket wheel and so on) must properly matethe shaft, which prevents bearing from breakage be-

-cause of over-loose mate.

4. Driverssuch as sprocket wheel and gear must be fitted close to bearings in order toreduce bending stre-

-ss of hanging shaft.

5. Whiteassembling motor of WPD reducer, it is necessary that proper amount of butterapplies to the worm

shaft input hole and keyway, avoiding assembling tootightly and rusting after using for a long time.

6. WhenOrdering or using all kinds of WPD type, if the motor weight is binger than thecommon, supporting

set is required.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Notices of usage

1 .Before using, please check carefully whether the reducer model, distance, ratio, input connecting method,

output shaft structure, input and output shaftdirection and revolving direction accord with requirement.

2 .According to the requirement of selecting lubricant oil in the productmanual, please fill proper category and

brand lubricant. And then screw on thevent-plug; Unlock the small cone-plug of vent-plug. Only after doing th-

ese, reducer is already for starting up running. The proper brand and adequatelubricant oil is required, replac-

ing oil in time conforming to the request ofproduct manual is also necessary, especially after using first 100 h-

ours, it isrequired refilling new oil.

3 .Whenabnormal circumstances occur, please stop and check reducer per solutions andreasons for faults of

reducer (allowable highest oil temperature is 95, under this temperature limit, ifoil temperature no more goes

up, please let reducer continue running.

About Xingda since 1984

Hangzhou Melchizedek Import & Export Co., Ltd. is a leader manufactur in mechanism field and punching/stamp

ing field since 1984. Our main product, NMRV worm gear speed reducer and series helical gearbox, XDR,

XDF, XDK, XDShave reached the advanced technique index of the congeneric European and Janpanese produc

ts, We offer standard gears, sprockets, chains, pulleys, couplings, bushes and so on. We also can accept orders

of non-standard products, such as gears, shafts, punching parts ect, according to customers' Drawings or sam-

ples.

Our company has complete set of equipment including CNC, lathes, milling machines, gear hobbing machine, g-

ear grinding machine, gear honing machine, gear shaping machine, worm grinder, grinding machines, drilling m-

achines, boringmachines, planer, drawing benches, punches, hydraulic presses, plate shearing machines and s-

o on. We have advanced testing equipments also.

Our company has established favorable cooperation relationships with sub-suppliers involving casting, raw mat-

erial, heat treatment, surface finishing and so on.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23