Diesel Heating Spraying and Drying Cabin for Heavy Machinery

Hangzhou Mig Packaging Co., Ltd. / 2022-06-23

- Type:Spray Booth

- Certification:CE

- Substrate:Steel

- Coating:Powder Coating

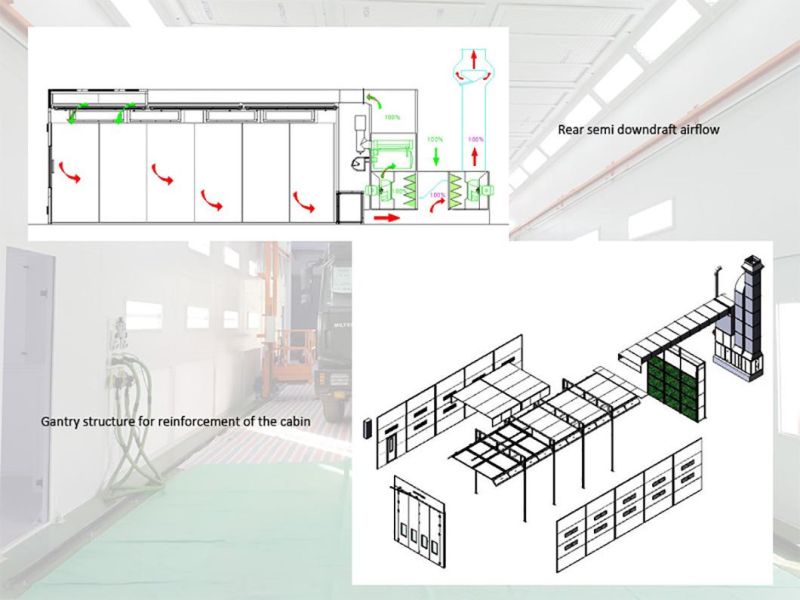

- Airflow Direction:Rear Semi Downdraft

- Heating Mode:Diesel

=== Base Info ===

- Model NO.:IT-15-5C

- Paint Mist Treatment:Dry-type

- Condition:New

- Airflow:Rear Semi Downdraft

- Plenum (Height):800mm

- Extraction Area:20m2

- Walls:60mm Rock Wool Walls

- Brightness:>1,000lux

- Air Volume:35,000m3,H

- Empty Loaded Air Speed:0.39m,S

- Heats:Riello Diesel Burner Rg5d*2

- Maximum Working:80 Celsius

- Controls:CE Standard

- Inverter:Schneider

- Stack Light:Yes

- Rated Power:30kw

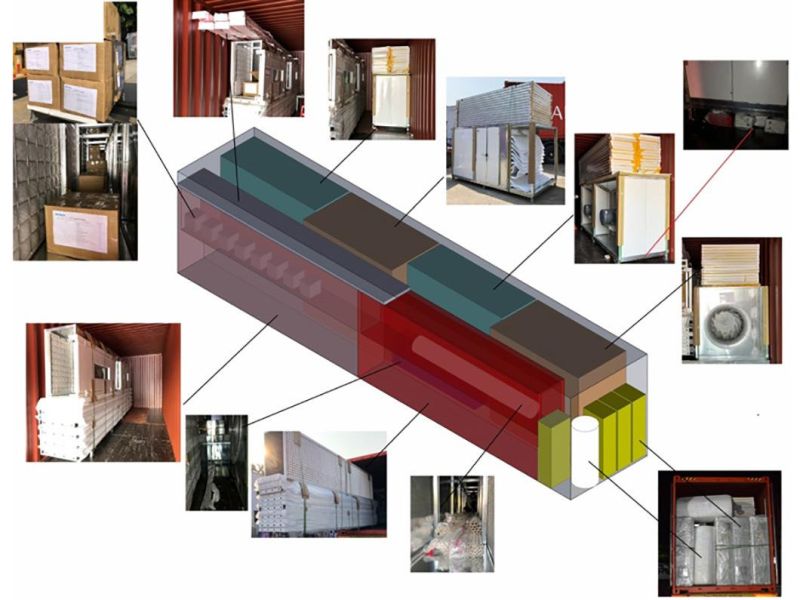

- Transport Package:Cargo Loaded on Steel Frame Handled by Forklifts

- Specification:15000 X 5000 X 5000mm (L X W X H)

- Trademark:INFITECH

- Origin:Guangzhou, China

- HS Code:8419899090

- Production Capacity:1000 Sets,Year

=== Description ===

Basic Info.

Model NO. IT-15-5C Paint Mist Treatment Dry-type Condition New Airflow Rear Semi Downdraft Plenum (Height) 800mm Extraction Area 20m2 Walls 60mm Rock Wool Walls Brightness >1,000lux Air Volume 35,000m3/H Empty Loaded Air Speed 0.39m/S Heats Riello Diesel Burner Rg5d*2 Maximum Working 80 Celsius Controls CE Standard Inverter Schneider Stack Light Yes Rated Power 30kw Transport Package Cargo Loaded on Steel Frame Handled by Forklifts Specification 15000 X 5000 X 5000mm (L X W X H) Trademark INFITECH Origin Guangzhou, China HS Code 8419899090 Production Capacity 1000 Sets/YearProduct Description

Diesel Heating Spraying and Drying Cabin for Heavy Machinery1.FEATURES

The truck spray booth IT-15-5C is designed for customers who look for economical solution.

This model comes standard with rear semi downdraft airflow. The air is extracted through rear exhaust plenum chambers, requiring no floor excavation.

It has robust cabin structure, rock wool walls, ceiling and sidewall lights, efficient air handling unit and easy-to-operate control. All these provide you with practical but cost-performance option and extraordinary experience.

Infitech can also provide you with customized solution according to your specific requirements.

2.SPECIFICATIONS

| ITEMS | SPECIFICATIONS |

| Model | IT-15-5C Rear Semi Downdraft Truck Spray Booth |

| Design standard | BS EN 13355: 2004+A1:2009 BS EN 60204: 2006+A1:2009 |

| Internal dimensions | 15000 X 5000 X 5000mm (L X W X H) |

| External dimensions | 17350 X 5170 X 5800mm (L X W X H) |

| Airflow | Rear Semi Downdraft |

| Plenum (height) | 800mm |

| Extraction | Exhaust plenum chambers at the rear |

| Extraction area | 20m2 |

| Entrance door | 4270x4800mm (WxH), 1 set |

| Service door | 800x2000mm(WxH), 4 sets |

| Walls | 60mm rock wool walls |

| Ceiling lights (LED) | 20 sets, each 4 X 18W, 1,440W total |

| Sidewall lights (LED) | 18 sets, each 4 X 18W, 1,296W total |

| Brightness | >1,000LUX |

| Filters | Bag filter, high efficiency ceiling filter, filter at exhaust plenum chambers, exhaust filter |

| Intake/Exhaust unit | Direct-type turbine fan, 1x11KW, SIEMENS motor |

| Air volume | 35,000m3/h |

| Empty loaded air speed | 0.39m/s |

| Heats | 315kw heat exchanger, RIELLO diesel burner RG5D |

| Maximum working temperature | 80ºC |

| Controls | CE standard control box |

| Inverter | SCHNEIDER inverter |

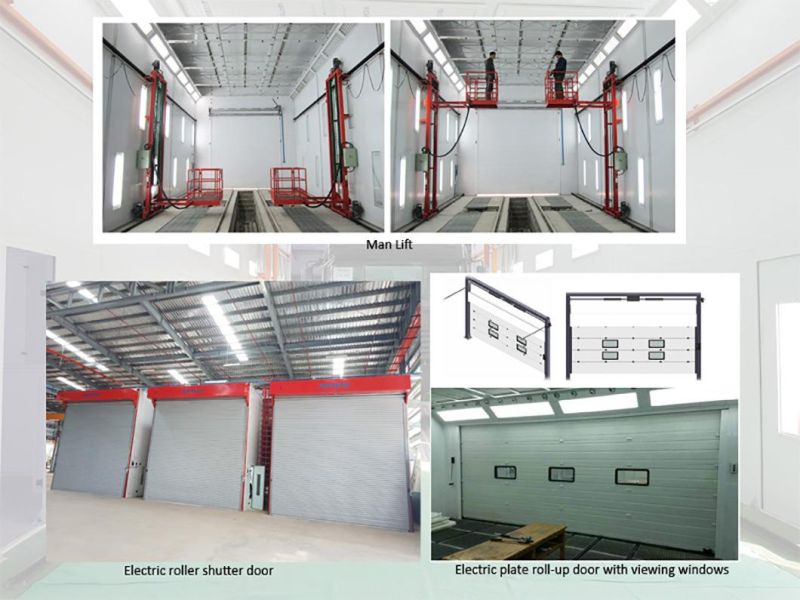

| Option | Man lift; Touch screen control; Electric entrance door |

| Rated power | 30KW |

3.DETAILS

AIRFLOW

Spray booth IT-15-5C comes standard with rear semi downdraft airflow.

It has front roof intake air plenum. Fresh air enters the booth from outside the building, ducted through the roof intake filters, and is drawn across the working chamber, over the vehicle and into the filtered exhaust chamber at the booth rear.

OPTION

- Downdraft with pit and grids in the ground for extraction

- Side downdraft airflow

REINFORCEMENT STRUCURE

INFITECH large size spray booth comes with gantry structure (made of square tubes) to reinforce the overall strength of the cabin.

MAIN ENTRY DOOR

- Manual entrance door with anti-falling device

LIGHTS

- Ceiling lightings (4*18W/set) and sidewall lights (4*18W/set) create shadow-free workspace.

OPTION

- Electric roller shutter door for the entry

- Electric plate roll-up door for the entry

AIR MAKEUP UNIT

| Intake and Exhaust Motor | Intake and Exhaust Fan | Air Volume | Drying System |

| 2*11KW, SIEMENS | IT750 backward centrifugal fan, direct linkage | 28,000m3/h | 315KW RG5D diesel burner |

OPTION

- Gas heating

CONTROL

- European standard control system

- Control box with manual buttons

UPGRADE

- Innovative digital screen control

FILTERS

| Item | Specification |

| Pre-filter | Bag filter |

| Ceiling filter | High efficiency F5 grade filter |

| Filters at rear exhaust plenum chambers | Pleated andreae filters + Fiberglass paint arrestor filter |

| Extract filter | Activated carbon filter |

OPTIONS

- Pneumatic man lift

- Electric roller shutter door

- Electric plate roll-up door

PACKAGING AND LOADING PHOTOS

The spray booth is generally delivered in various sub components palletized and in different packaging to be handled by forklifts. In some cases the components are systematized loose.

The following photos show how we pack and load the cargo.

FAQQ: What are the dimensions of the rear wall exhaust plenum chambers?A: 5000 X 660 X 4000mm(L X B X H)

Q: Can I put the machinery at the top of the truck spray booth?A: Yes.

Q: Can I have bigger width for the truck spray booth?A: Certainly. In terms of the dimensions and configurations, we can follow your request. Please send your requirements through, we will work out the solution for you to check.

Q: Can you send your engineer to help with the installation?A: Upon your special request, we can send one or two technicians over to offer technical guidance during the installation, and commissioning process. There is additional cost for the technical guidance service.

Q: Can you design the spray booth according to my requirements?A: Yes. We have in-house design team who has abundant experience in providing you with customized service. And we have many non-standard spray booth projects before.

Q: How long is the schedule?A: Usually, the standard production lead time for a standard truck spray booth is approx. 30 days.

Q: What about the warranty?A: 2-year warranty for main components.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23