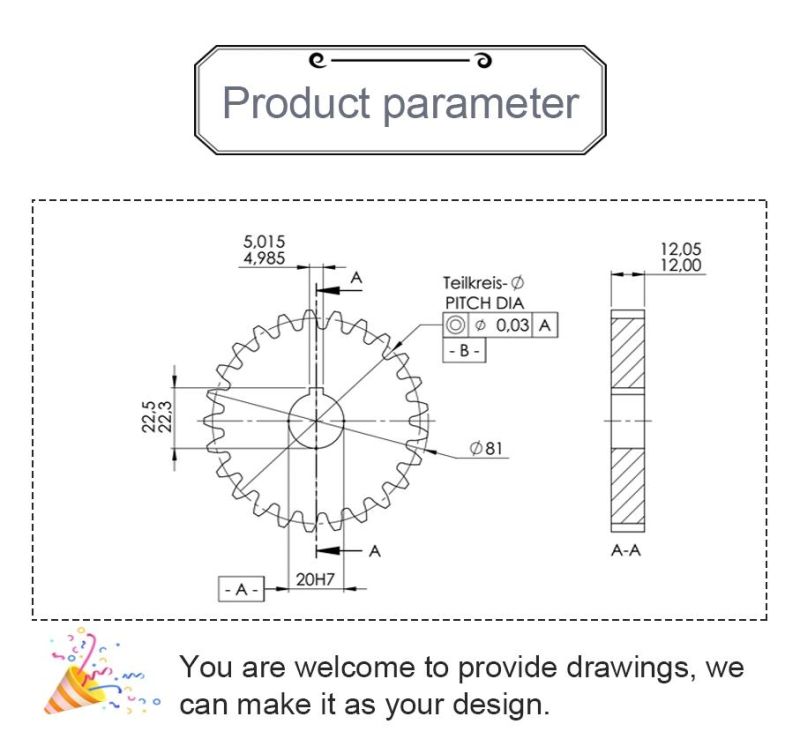

Custom Made CNC Metal Machining Transmission Gear

Weifang Karry Plastic Products Co., Ltd. / 2022-06-27

- Application:Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car

- Hardness:Hardened Tooth Surface

- Gear Position:Internal Gear

- Manufacturing Method:Cut Gear

- Toothed Portion Shape:Spur Gear

- Material:Stainless Steel

=== Base Info ===

- Model NO.:WF-SA

- Type:Worm And Wormwheel

- Item:Customized Machining Gears

- Raw Material:Stainless Steel, Carbon Steel

- Size:as Your Requirement

- Techincs:Machining

- Brand Name:Shengao,OEM

- Standard or Nonstandard:Nonstandard

- Factory:Over 15 Years Experience in Producing

- Precisoin:High

- Inspection:Differential Planetary Gear

- Surface Treatment:Hobbing,Shaving,Grinding

- OEM Service:Yes

- Custom Made:Yes

- Logo Printing:Customized

- MOQ:10-1000PCS

- Free Sample:Yes

- Transport Package:Plywood Box

- Specification:OEM

- Trademark:Shengao

- Origin:Weifang City, Shandong Province, China

- HS Code:87089910

- Production Capacity:5000PCS,Month

=== Description ===

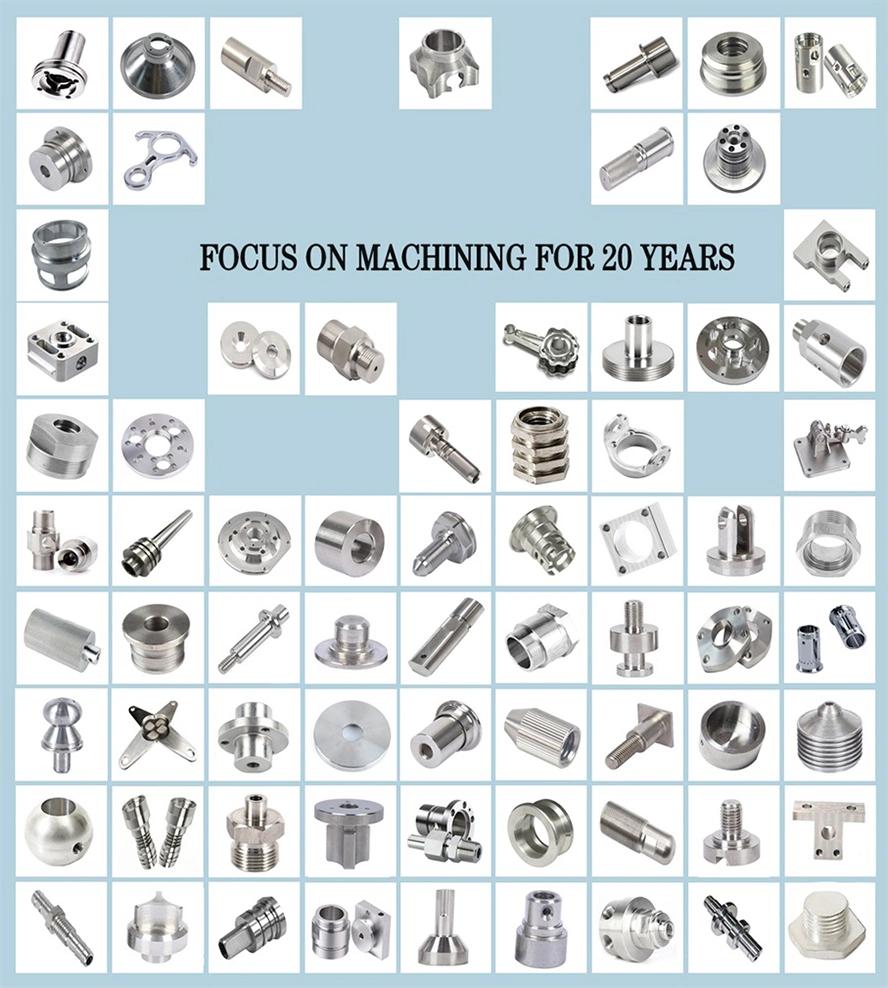

Auto Parts/Motocycle parts/Contruction Parts/Furniture Parts/Electronic Parts

PRODUCT DESCRIPOTION

1. Crown wheel and pinion gears and spiral bevel gears for automobile rear axle, truck, tractor

front/rear axle and tool.

2. Raw material: 20CrMni 22CrMo 8620 SCM420

Processing: Forging, normalizing, rough, machining, fine finishi, carburizing, tempering,

annealing, accurate grinding, matching and testing, packing.

3. The tooth surface is finished by lapping machine, the color will be silver gray

4. Hardness about surface: HRC58-62, internal: HRC35-40.

5. We can process gears according to customers drawing and samples.

Inspections:

3D instruments, 2D instruments, Projectors, Height Gauges, Inner diameter dial indicators, Dial gaues, Thread

and Pin gauges, Digital calipers,Micro calipers, Thickness testers, Hardness testers Roughness testers, etc.

( Detection accuracy to 0.001 millimetre )

| Mininum of Quantity | 100 Piece/Pieces |

| Unit Weight | 0.5kg~300kg |

| Price | FOB Qingdao,China,USD1.5~1.9 |

| Packing Details | Paper Box in Wooden Pallet |

| Delivery Time | One month |

| Payment Terms | L/C, T/T |

| Machining | CNC or |

| Supply Capacity | 50 Metric Tons per Month |

| Standard | DIN,ASTM,GOST,B |

Packing:

1: Shrink film+ bulk loading

2: Shrink film +Carton box + Pallet/ wooden case

3: PP + Wooden case

4: As per customers' requirements or negotiated

Q1: How can I get cnc spare parts sample?

Q1: How can I get cnc spare parts sample?1. Sample fee will be free if we have in stock, you just need to pay the shipping cost is OK.

2. The sample of your own design needs to pay for the mold set up charge. Samples production takes 5-7 working days after set up charge received & size drawing approval.

Q2: How to pay for the order?

There are 4 options to pay the order: Bank Transfer; Western Union; Paypal; Payoneer. Kindly choose the most suitable way for you to arrange it.

Q3: What is the shipping method?

The samples were sent out by international airway express company like DHL, UPS, FedEx, TNT. Usually takes around 5-7 working days (door to door service). We arrange goods shipment via sea or air.

Q4: Can you give me help if my products are very urgent?

Yes, We can work overtime and add a few machines to produce these products if you need it urgently.

Q5: I want to keep our design in secret, can we sign NDA?

Sure, we will not display any customers' design or show to other people, we can sign NDA.

You can look through our website to find your interest or email your any questions through

below approach! We will reply to you within 12 hours.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23