Custom OEM A356+T6 Squeeze Die Casting Aluminum Car Steering Knuckle

Wuxi Xinrun Protective Film Co., Ltd. / 2022-06-24

- After-sales Service:1year

- Warranty:1year

- Type:Steering Gears,Shaft

- Material:Alloy

- Certification:ISO, AISI, DIN, API, CE, ASTM, JIS, GB, BS, DOT

- Automatic:Automatic

=== Base Info ===

- Model NO.:CEX-01

- Standard:Nonstandard

- Condition:New

- Equipment:200-1100t Casting Machine

- Surface:Trimming, Deburring,Polishing, Shot Blasting

- Type of Material:A356.2

- Process:Squeeze Casting , Liquid Forging

- Advantage:High-Strength High Density

- Description:Aluminum Alloy Squeeze Casting Vehicle Parts

- Transport Package:Carton

- Specification:OEM

- Trademark:CEX

- Origin:Qingdao, China

- HS Code:7616991090

- Production Capacity:1000tons,Month

=== Description ===

Basic Info.

Model NO. CEX-01 Standard Nonstandard Condition New Equipment 200-1100t Casting Machine Surface Trimming, Deburring,Polishing, Shot Blasting Type of Material A356.2 Process Squeeze Casting / Liquid Forging Advantage High-Strength High Density Description Aluminum Alloy Squeeze Casting Vehicle Parts Transport Package Carton Specification OEM Trademark CEX Origin Qingdao, China HS Code 7616991090 Production Capacity 1000tons/MonthProduct Description

Custom OEM A356+T6 Squeeze Die Casting Aluminum Car Steering Knuckle

Product parameter

| Process | Aluminum Die casting, Squeeze casting+T6, Zinc Alloy die casting,CNC machining, Turning |

| Equipment | Cold chamber die casting machine:200T/280T/400T/600T/800T/1100T.CNC centers, CNC turning, CNC lathes, electrical pulse, line cutting, milling, drilling, grinding |

| Material | A319, A356, A360, A369, A380, A383, A384, A413, A535, 44300, 44300, 46000, AlSi9Mg, AlSi9Cu3, ADC12, ZL102, ZL104, ZL108, Zamak2,3,5,7 ect. Squeeze Casting: A356+T6, A356.2+T6, AlSi9Mg+T6, Zl108+T6, AlTi-Alloy+T6 |

| Surface | Trimming, Deburring,Polishing, Shot blasting, Sand blasting,Tumbling, Powder coating, Anodizing, Chrome, Zinc, Electrophoresis, Passivation, Chemical coating. |

| Software Assistance | Pro-e/Solid work/UG/Auto CAD/CATIA |

| Products Application | Automotive industry, Bicycle and motorcycle, Door and windows and furniture, Household appliance, Gas meter, Power tool,LED lighting, Medical instrument parts, ect. |

Product Show

Our Equipment

-Die-casting equipment (160T-1100T Casting Machine )

-injection molding equipment

-Precision CNC lathes

-Milling machines

-Ultrasonic welding machines

-Avarious auxiliary processing machinery.

Our New Porcessing Technology -Squeeze Casting

Aluminum alloy Liquid forging also called Squeeze casting. The principle is to fill the molten or semi-molten metal or alloy in the mold cavity, and then apply high pressure to plastically deform the solidified metal. The unsolidified metal is subjected to isostatic pressure and high-pressure solidification occurs at the same time then get the parts or blanks, T6 heat treatment can be performed to obtain high-strength, high-precision parts.

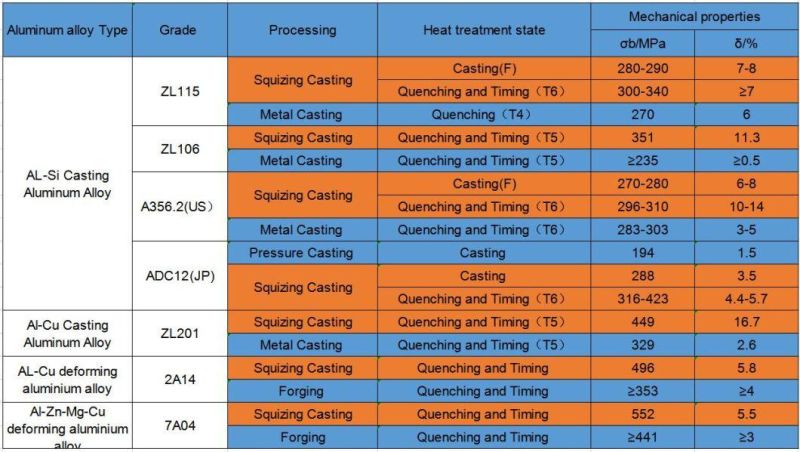

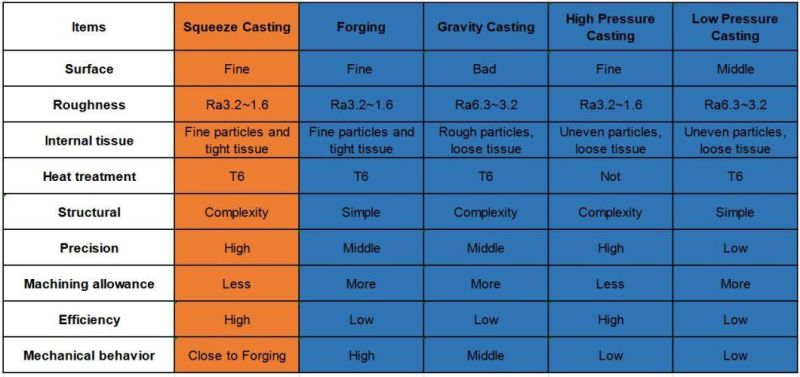

Mechanical properties-- Compare with other Casting

Integrated the advantages of forging and Traditional die casting

Packing

Packing

Why Choose us ?

--20 Years Aluminum Die casting Experience .

--Drawings--Mold development--Casting production--Surface treatment one-stop service .

--Manufacture factory with Competitive price , Higher quality .

--Leading domestic aluminum alloy squeeze casting technology .

FAQ

1. How can I get the quotation?

Please send us information for quote: drawing, material, weight, quantity and request.

2. If we don't have drawing, can you make drawing for me?

Yes, we make the drawing of your sample and duplicate the sample.

3. When can I get the sample?

Sample: 15-20days after you start to make mold. The accurate time depends on your product.

4. What is your main order time?

Order time:20-25 days after the payment. The accurate time depends on your product.

5. What is your payment method?

Tooling: 100% TT advanced.

Main order: 50% deposit, balance 50% to be paid before shipment.

6. Which kind of file format you can read?

PDF, ISGS, DWG, STEP, MAX..

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23