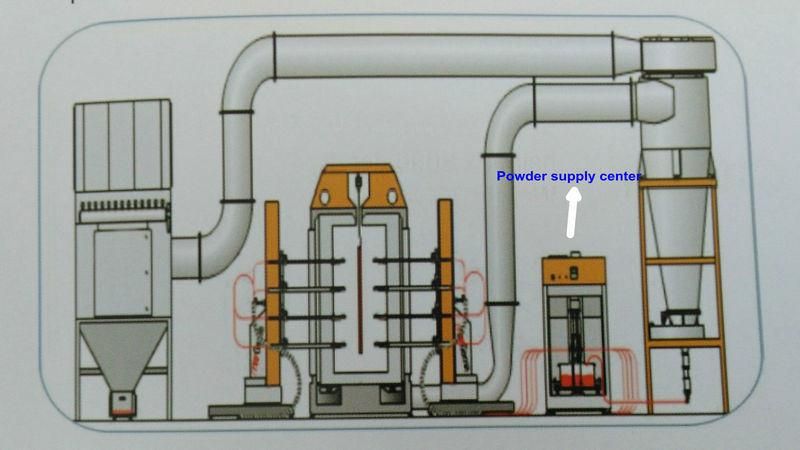

Powder Feed Center of Cyclone Recycle Booth Systems

Coolpack Canton Industrial Limited / 2022-06-23

- Type:Coating Production Line

- Certification:CE

- Substrate:Steel

- Brand:Hicolo

- Coating:Powder Coating

- Airflow Direction:Cross-flow Type

=== Base Info ===

- Model NO.:COLO-6000PC

- Heating Mode:Diesel

- Paint Mist Treatment:Dry-type

- Condition:New

- Use:Powder Supply

- Working:Automatic

- Voltage:110V,220V

- Delivery Time:14 Days

- Transport Package:Wooden Carton

- Specification:1500x1200x130mm

- Trademark:HICOLO

- Origin:China

- HS Code:8424899990

- Production Capacity:30 Per Month

=== Description ===

Basic Info.

Model NO. COLO-6000PC Heating Mode Diesel Paint Mist Treatment Dry-type Condition New Use Powder Supply Working Automatic Voltage 110V/220V Delivery Time 14 Days Transport Package Wooden Carton Specification 1500x1200x130mm Trademark HICOLO Origin China HS Code 8424899990 Production Capacity 30 Per MonthProduct Description

Powder Feed Center Of Cyclone Recycle Booth Systems1.The powder feed central system provides fast color change.

2.The automatic spray gun, various powder hoses, and injectors will stay clean automatically

during color change.

3.A filter system maintains a comfortableindoor environment by transferring dusts during cleaning.

4.It does not require cleaning when changing the powder coating box

5.The unit is fullyprogramable.

Automatic vibrating powder feed center parameters

Power supply voltage | 1P 220VAC (110V) |

Power | 500W |

Gas pressure | 0.6-0.8MP |

powder pump | 16pcs(max) |

Powder supply center

Control system:

Touch screen operator panel and keyboard input increase the supply of new powder automatically.

Automatic matching of old and new powders together.

How does the powder feed center work?

Put the powder hopper full with powder in the powder supply room, and on the powder hopper vibration platform,

and then access the air for the fluidization of powder. Vibration platform will vibrate at intervals.

Powder particles generated in the process of fluidization goes through the rear ventilation pipe so that powder doesn't spill.

In the process of powder gun working, the powder pump station will be decreased, so that the suction tube is inserted into fluidizing powder.

Control the pump station decreasing by powder detecting sensor, so that the powder suction tube keep been inserted into the sufficient fluidization powders.

With powder level declining, when the powder level reaches the lower limit, the powder center of the electronic control system

will issue audible alarm and on the touch screen with character note. Remind the operator low powder level alarm, and he or she needs to add powder.

In the cleaning process, lower the pump platform down to the powder cleaning level. Open and clear the powder. Powder center automatically blowbacks the

powder gun hoses of both sides alternately.

If change the color, rise the pump station to higher point for the powder hopper can be easily removed, and then carried the powder hopper with required color in.

More details,please contact with us.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23