Ybc251 Ztgd0404-Mg Tungsten Carbide Parting and Grooving Inserts

ZHANGJIAGANG HUAXING PACKING CO., LTD. / 2022-06-09

- Coating:Coating

- Application:Grinding Machine, Milling Machine, Lathe

- Structure:Indexable Turning Tool

- Material:Tungsten Steel

- Type:Lathe Turning Tool

- Usage:Milling Steel

=== Base Info ===

- Model NO.:YBC251 ZTGD0404-MG

- Surface Coating:CVD

- Grade:Ybc251

- Item Number:Ztgd0404-Mg

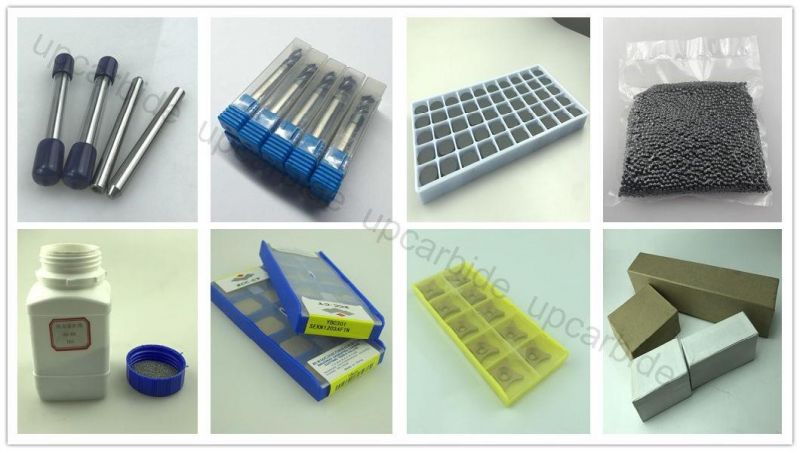

- Package:10PCS Each Inner Box

- Transport Package:Inner Box+Carton

- Specification:YBC251 ZTGD0404-MG

- Trademark:ZZUP or ZCCCT

- Origin:Zhuzhou, Hunan, China

- HS Code:820900100

- Production Capacity:10000000PCS,Month

=== Description ===

Packing details

Shipping ways

Production process

Contact details

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23