Stainless Steel Screw Jack Vs. Aluminum Screw Jack, Stainless Steel Jacks Vs. Aluminium Screw Jacks, Corrosion Resistance Screw Jacks Vs. Hygienic Screw Jacks

Shandong Hengda Brand Packaging Co., Ltd. / 2022-06-27

- Application:Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car

- Hardness:Hardened Tooth Surface

- Installation:Vertical Type

- Layout:Coaxial

- Gear Shape:Worm Screw and Worm Gear

- Step:Single-Step

=== Base Info ===

- Model NO.:2.5 kN to 350 kN

- Type:Worm Reducer

- Transport Package:Standard Exporting Plywood Cases

- Trademark:JACTON

- Origin:Made in China

- HS Code:8428909090

- Production Capacity:30000 Sets Per Year

=== Description ===

Basic Info.

Model NO. 2.5 kN to 350 kN Type Worm Reducer Transport Package Standard Exporting Plywood Cases Trademark JACTON Origin Made in China HS Code 8428909090 Production Capacity 30000 Sets Per YearProduct Description

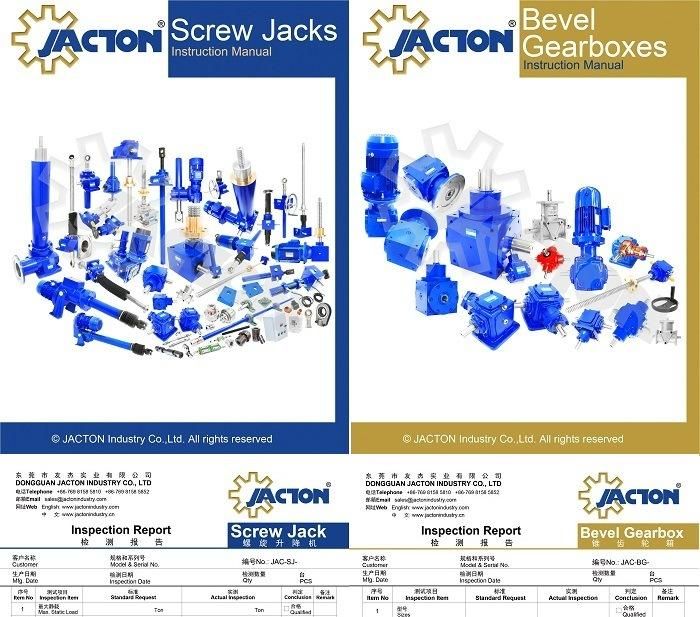

Stainless Steel Screw Jack Vs. Aluminum Screw Jack, Stainless Steel Jacks Vs. Aluminium Screw Jacks, Corrosion Resistance Screw Jacks Vs. Hygienic Screw Jacks. How to select the most suitable type Corrosion Resistant Screw Jacks for Hygienic Applications, Filling, Food, Pharmaceutical And Beverage?Stainless Steel Screw Jacks are ideal for use in demanding environments where corrosion resistance is required. All standard components(threaded spindles, covers, bushings, casings, end fittings and motor flanges) are manufactured from 300 series Stainless Steel materials. These mechanical jacks use a stainless steel worm with a high strength bronze worm gear(drive sleeve). Load capacities for Stainless Steel Machine Screw Jacks range from 1-ton to 35-tons. These stainless steel jacks options include Anti-Backlash, Anti-Rotation (Keyed) and Safety Nut designs.

Upright Translating Stainless Steel Screw Jacks: A Upright translating jack has a lifting shaft that moves through the gear box. The lift shaft extends out from the top of the worm screw jack. A nut is integrated with the worm gear such that the worm gear and nut rotate together. When the lift shaft is held to prevent rotation, the lift shaft will move linearly through the gear box to move the load.

Inverted Translating Stainless Steel Screw Jacks: A Inverted translating jack has a lifting shaft that moves through the gear box. The lift shaft extends out from the bottom of the worm screw jack. A nut is integrated with the worm gear such that the worm gear and nut rotate together. When the lift shaft is held to prevent rotation, the lift shaft will move linearly through the gear box to move the load.

Upright Rotating Stainless Steel Screw Jacks: A Upright Rotating Screw Jack has a lift shaft that moves a nut as it turns. The lift shaft is fixed to the worm gear. This causes the load, which is attached to the travel nut, to move along the lift shaft. A Upright Rotating Screw jacks has the lift shaft extending out the top of the jack.

Inverted Rotating Stainless Steel Screw Jacks: A Inverted Rotating Screw Jack has a lift shaft that moves a nut as it turns. The lift shaft is fixed to the worm gear. This causes the load, which is attached to the travel nut, to move along the lift shaft. A Inverted Rotating Screw jacks has the lift shaft extending out the bottom of the jack.

Compared with Stainless Steel Screw Jacks, Cubic type in the compact design Aluminum Screw Jacks with anodized aluminum housing for light duty, light weight and low cost. Available in load capacity 1/4-ton, 1/2-ton, 1-ton and 2.5-ton. Worm and Worm Screw are made in high tensile Alloy Steel (custom-made Stainless Steel), Worm gear is made in high tensile Bronze. Screw Translating, keyed screw for anti-rotation, and travelling nut are avaiable.

Shipment and Packing Pictures

Shipping:

1. Ocean freight: seaport to seaport, price terms CIF, FOB, EXW, CFR etc.

2. Air freight: airport to airport, price terms EXW, CRF etc.

3. Air courier: DHL, FEDEX, UPS, TNT door to door shipment, price terms DDU, CPT etc.

Packing:

100% standard exporting plywood cases.

Note: International Exporting Standard Wooden Material with Free Fumigation.

JACTON Advantages

1. International standard materials for All JACTON brand products. We insist on choosing brand suppliers to supply the high quality raw materials to control the producing process. Optimization constantly the production processes, inspecting in each link and managing production site.

2. 100% quality assured with double quality inspections. The quality inspection by quality inspectors from processing to finished products as the first time. Before packing, the corresponding sales engineers must inspect the orders following the paper drawings, order quantities and special markings in the invoice or sales contracts as the second time. After that, fill in the inspection report with signature and company stamp.

3. 100% safety transportation. Packing with strong standard export plywood cases materials (free fumigation), inner packing with epe foams to prevent products swaying and outer packing with iron sheets and fasteners to fasten the packages.

4. Internationl sales engineers have professional knowledge and skills on our standard products and service. They have enough ability to solve the basic technical problem immediately whatever by phone, online chat, face to face communications.

5. All the standard products with 2D CAD Drawings (PDF, DWG and DXF formats), and 3D CAD Models (STEP, STP, MODEL, IGS, PRT and CATParT formats).

6. Custom design available, OEM service available, Free engineering advice, Free quotes available and Customer label available.

7. Inspection equipments include motor with inverter drive system, height adjustmemt motorized lifting system, coordinate measuring machines, outside micrometers, inside micrometers, depth calipers, vernier calipers, digital calipers, hardness testers, digital noise meters, industrial infrared thermometers, digital speed measuring instruments, digital multimeters, and high precision clamp digital ammeter etc.

8. Processing with modern advanced machines such as CNC gear hobbing machines, CNC flank grinding machines, CNC cylindrical grinding machines, multi-axis CNC milling machines, CNC lathes and others equipments.

Finished Projects

1. Theatrical solutions stage and orchestra platform lifts projects. Customers are from France, Australia, Netherlands, United Kingdom, Spain and Canada.

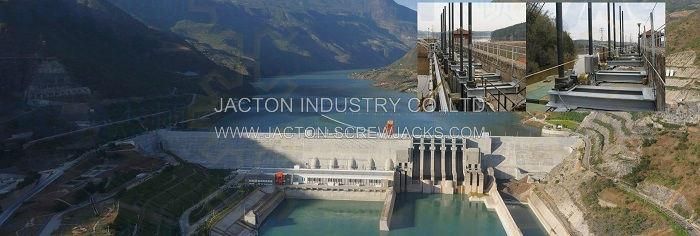

2. Hydroelectric power station projects and water conservancy projects. Customers are from Vietnam, Australia, Malaysia, Russian Federation, Nepal, Pakistan, Belgium, United States and United Kingdom.

3. Aircraft maintenance platforms and docking systems projects. Customers are from Pakistan, Singapore and United Arab Emirates.

4. Solar panel tracking system projects. Customers are from Spain, India and Canada.

5. Bolted steel storage tanks and silos lifting solutions. Customers are from South Africa, United States, Mexico, Russian Federation, Brazil and Vietnam.

6. Dish antenna elevation and azimuth positioning projects. Customers are from Singapore, Malaysia and United States.

7. Railway wagon projects. Customers are from South Africa.

8. Beverage can production lines. Customers are from Netherlands, United States, Thailand and Indonesia.

9. Steel factories production lines. Customers are from Iran, United States and Turkey.

10. Continuous PU sandwich panel production lines. Customers are from Thailand and United Kingdom.

JACTON Customers Areas(Countries)

1. American Countries: United States, Mexico, Canada, Chile, Bolivia, Brazil, Colombia, Dominican Republic, Honduras, Costa Rica, Panama, Puerto Rico, Jamaica, Trinidad and Tobago, Aruba, Argentina, Peru, Venezuela.

2. European Countries: Russia, Germany, Turkey, France, United Kingdom, Italy, Spain, Ukraine, Poland, Romania, Netherlands, Belgium, Greece, Czech Republic, Portugal, Sweden, Hungary, Belarus, Austria, Switzerland, Bulgaria, Denmark, Finland, Slovakia, Norway, Ireland, Croatia, Georgia, Armenia, Lithuania, Slovenia, Estonia, Cyprus, Luxembourg, Iceland.

3. Asian Countries: Malaysia, Indonesia, Singapore, Pakistan, Philippines, Vietnam, United Arab Emirates, Thailand, Saudi Arabia, Iran, Turkey, India, Nepal, Yemen, Taiwan, Sri Lanka, Israel, Jordan, Kuwait, Qatar.

4. Oceanian Countries: Australia, New Zealand, Fiji.

5. African Countries: South Africa, Egypt, Ethiopia, Nigeria, Kenya, Tanzania.

JACTON Products List

1. Manual Screw Jacks, Electric Screw Jacks.

2. Screw Jacks Series: JT series acme screw jacks, JTC series cubic screw jacks, JTW series machine screw jacks, JTM series worm screw jacks, JTB series ball screw jacks, JTD series cubic ball screw jacks, JSS series stainless steel screw jacks, JTS series bevel gear screw jacks, Non-standard series screw jacks.

3. Bevel Gearboxes Series: JT series bevel gearboxes, JTP series cubic bevel gearboxes, JTA series aluminum bevel gearboxes, JTH series hollow shaft bevel gearboxes, BSS series stainless steel bevel gearboxes.

4. Lifting Systems and Systems Accessories: two-jacks systems, three-jacks systems, four-jacks systems, six-jacks systems, eight-jacks systems. Accessories cover couplings, universal joints, cardan shafts, connecting shafts, electric motors, geared motors and reducers, hand wheel with crank handles, pillow block bearings, flange block bearings, rod end bearings, stop nuts, limit switches, safety nut, travel nuts, linear shafts and bearings, linear guides and bearings, telescopic spring covers, bellows boot, protective tube, trunnion adapter plates, trunnion mounting brackets, motor flanges, rotary encoders, potentiometers, frequency inverters and position indicators etc.

5. Electric Linear Actuators Series: Parallel heavy duty linear actuators, In-line heavy duty linear actuators.

6. Geared Motors and Speed Reducers Series: helical gearmotors R series, helical bevel gearmotors K series, parallel shaft helical gearmotors F series, helical worm gearmotors S series, small AC gear motor series and worm gear motor reducer series.

Contact Information

JACTON Industry Co.,Ltd (VAT No.: 9144190007026567X3, registered Capital 500000CNY) is a leading manufacturer and supplier of Screw Jacks (Mechanical Actuators), Bevel Gearboxes, Lifting Systems, Electric Linear Actuators, Gearmotors and Speed Reducers, and Others Linear Motion and Power Transmission Products in China. We are Alibaba, Made-In-China and SGS (Serial NO.: QIP-ASI192186) audited manufacturer and supplier. We also have a strict quality system, with senior engineers, experienced skilled workers and practiced sales teams, we consistently provide the high quality equipments to meet the customers electro-mechanical actuation, lifting and positioning needs. JACTON Industry guarantees quality, reliability, performance and value for today's demanding industrial applications.

Website (English): screw-jacks.en.made-in-china.com

Website (English): screw-jacks.en.made-in-china.com

Website (Chinese): screw-jacks.en.made-in-china.com

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23