Customized Conveying Machinery Parts Wear-Resistant Nylon/PE Bottle Feeding Screw

Foshan Le Ying Craftwork Factory / 2022-06-27

- Standard or Nonstandard:Nonstandard

- Feature:Anti-Static, Oil-Resistant, Cold-Resistant, Corrosion-Resistant, Alkali-Resistant, Wear-Resistant, Acid-Resistant

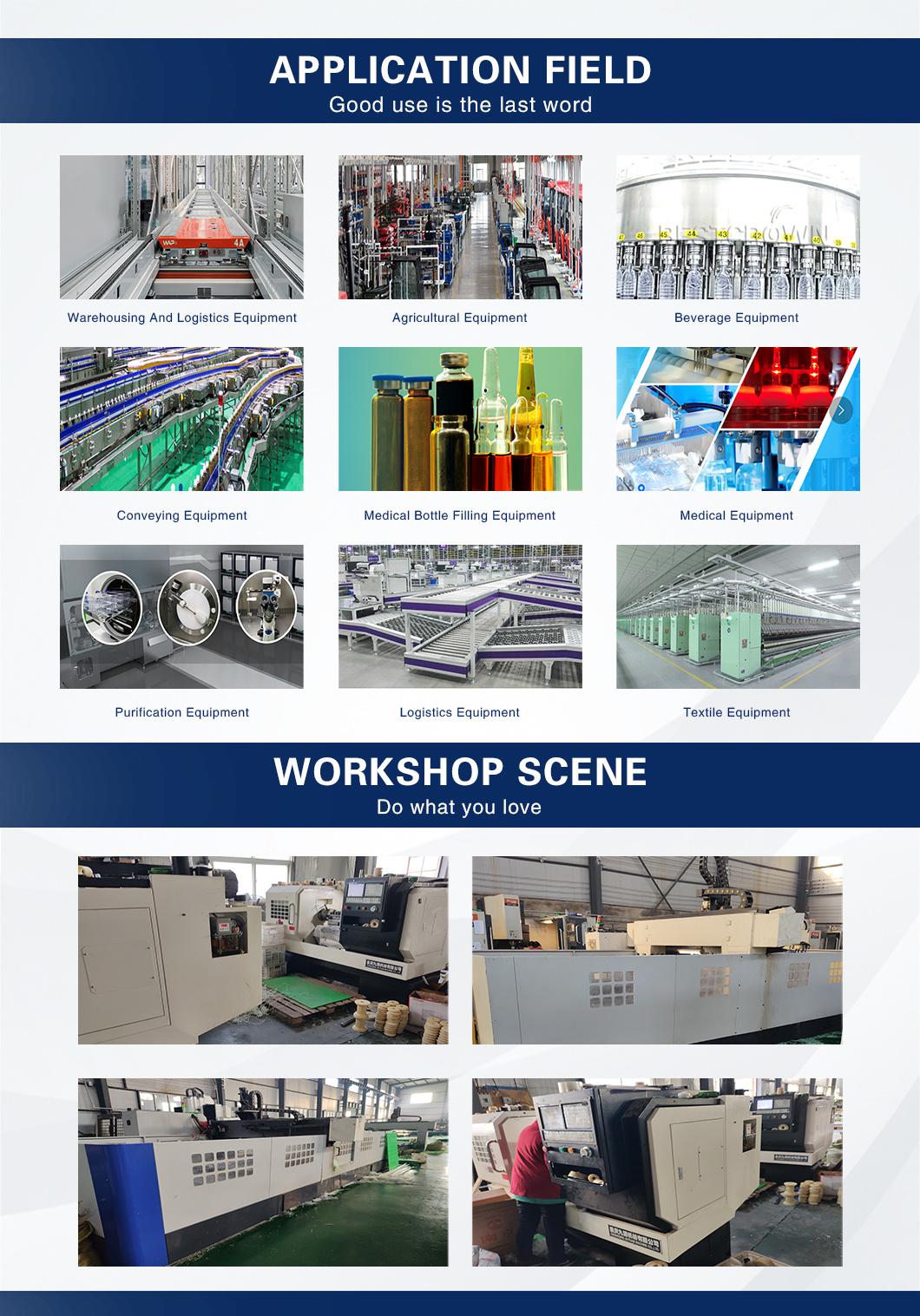

- Application:Conveyer Equipment, Packaging Machinery, Food Machinery, Mining Equipment, Agricultural Machinery

- Surface Treatment:Chamfering and Polishing

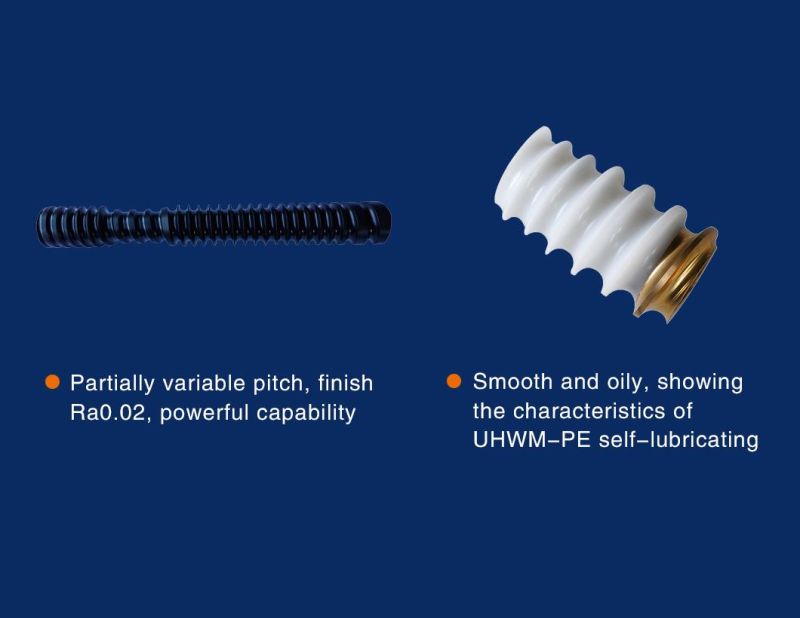

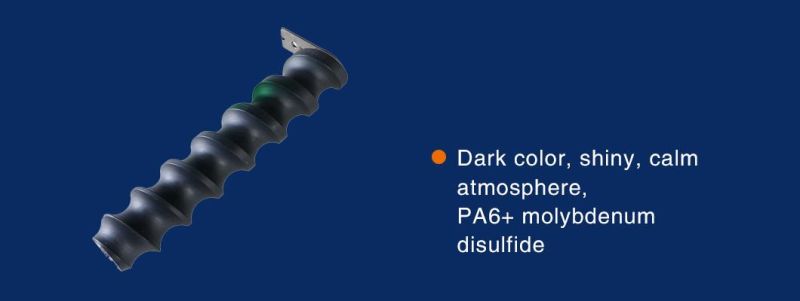

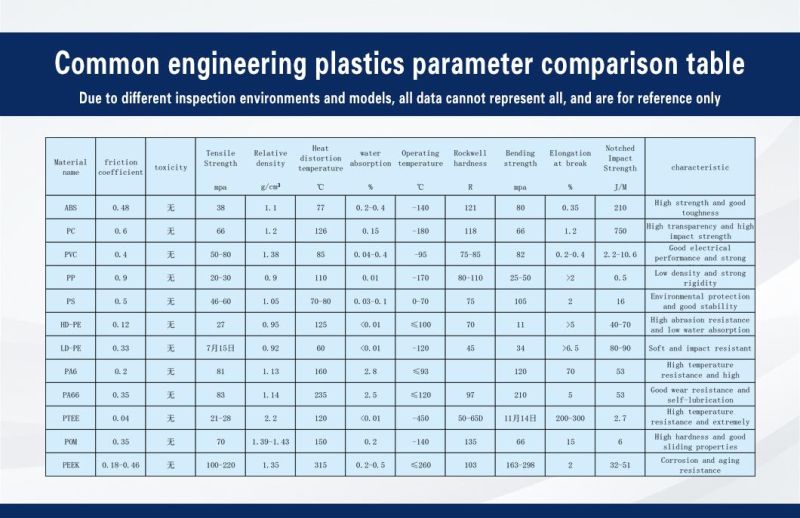

- Material:UHMW-PE and Oily Nylon

- Properties:Self-Lubricating

=== Base Info ===

- Scope of Application:Labeling Machine Machinery

- Shape:Spiral

- Transport Package:Carton. Wooden Box. Tray etc

- Specification:Customer settings

- Trademark:YiBao

- Origin:China

- Production Capacity:10000 Pieces,Yea

=== Description ===

Overview

Product Description

Product Highlights

Product Highlights

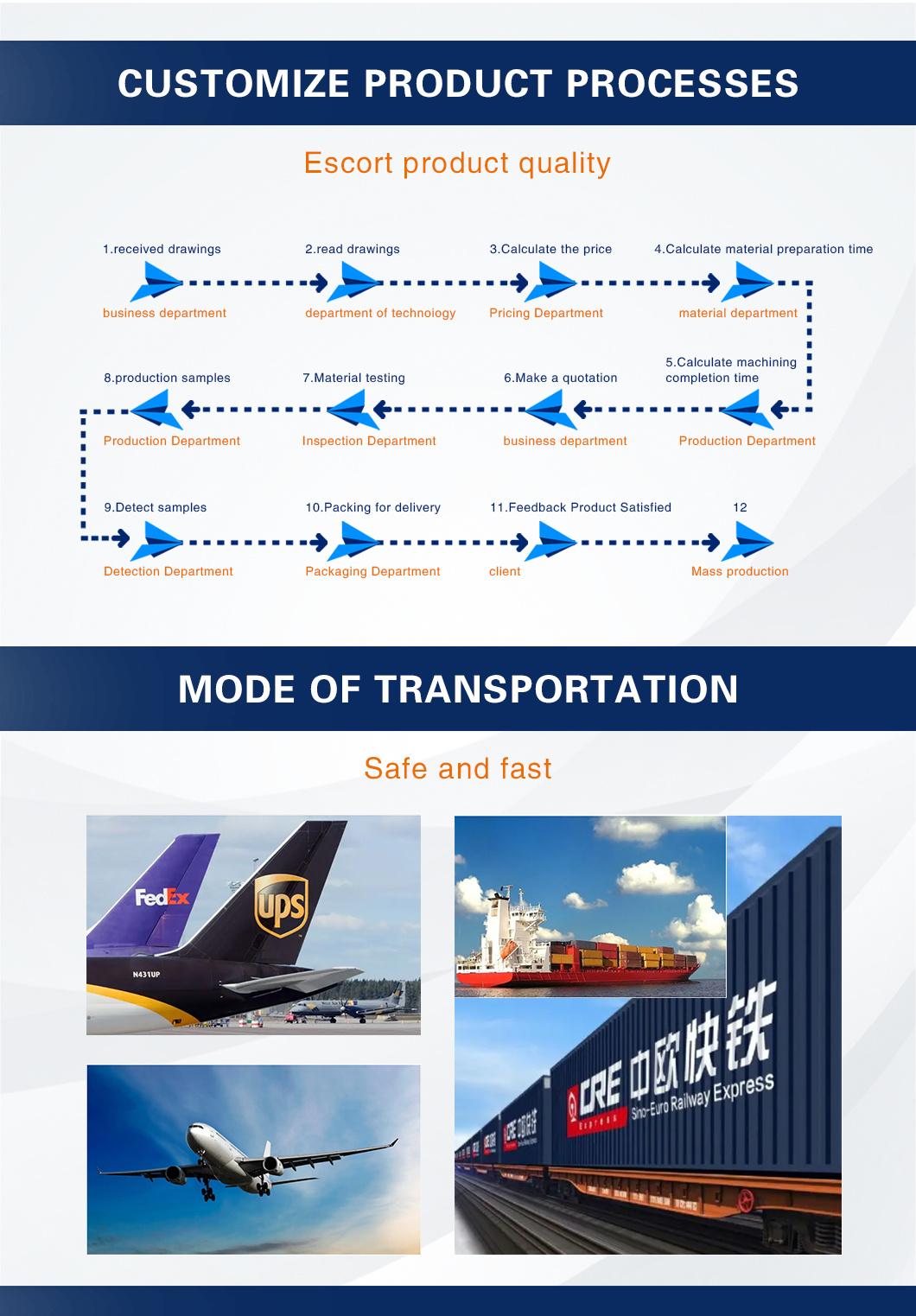

Mass production and shipping

Mass production and shipping

Requirements And Materials For Bottle Entry And Exit Screw And Can Turning Devices

In And Out Bottle Screw

(1) The container should move smoothly along the bottle feeding screw

(2) Smoothly guide the container into the spiral groove at the bottle-feeding end

(3) The container at the bottle end and the star-shaped dial can be smoothly connected

Turnover device

(1) The container is turned very smoothly along the spiral inner cavity to the required angle

(2) The movement of the container surface in the inner cavity will not produce scratches and deformation.

(3) The movement of the container in the inner cavity is not impacted by the frontal external force.

Due to the large number of pushing bottles or cans and easy wear and tear, the container is generally fragile and easily deformed, so it is required to minimize the impact when pushing the bottle, so the selected materials for the screw and turning device should have high wear resistance, High strength, self-lubrication, no internal stress, no seesaw deformation, easy to process and so on.

Jingxian Yibao Rubber & Plastic Products Co., Ltd. recommends that you can choose the engineering plastic UHMW-PE with superior performance and oily nylon material as the material for making the screw in and out of the bottle and the can turner.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23