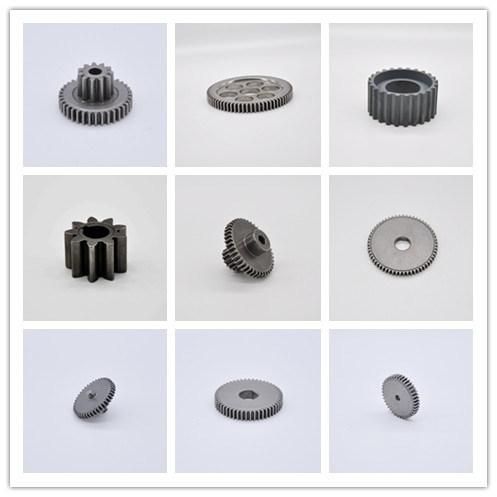

Sintered Alloy Metal Parts Powder Metallurgy Gears

Qingdao Yanfei Rigging Co., Ltd. / 2022-06-27

- Application:Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car

- Hardness:Hardened Tooth Surface

- Gear Position:External Gear

- Manufacturing Method:Sintered Gear

- Toothed Portion Shape:Spur Gear

- Material:Iron Alloy Powder

=== Base Info ===

- Type:Circular Gear

- Density:6.4-7.4 g,cm3

- Transport Package:PE Bag, Bubble Bag, Carton, Pallet

- Trademark:HLXCL

- Origin:China

- Production Capacity:5000000pieces,Year

=== Description ===

Basic Info.

Type Circular Gear Density 6.4-7.4 g/cm3 Transport Package PE Bag, Bubble Bag, Carton, Pallet Trademark HLXCL Origin China Production Capacity 5000000pieces/YearProduct Description

PM metal iron stainless steel powder metallurgy OEM GEARS

| Product Name | High precision gear manufacturers by powder metallurgy |

| Material | Iron powder, alloy powder,precious metal powder |

| Technology | Sintering - Powder Metallurgy |

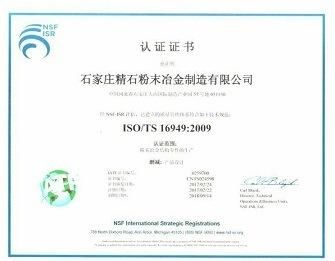

| Certificate | ISO9001/TS16949 |

| Surface Treatment | High frequency quenching, oil impregnation,CNC,vacuum cleaning,polishing, |

| Apperance | No crumbling, cracks, exfoliation, voids, metal pitting and other defects |

| Process Flow | Powder mixing - Forming - Sintering - Oil impregnation - Sizing -Ultrasonic cleaning - Steam oxidation - Oil impregnation - Final inspection - Packing |

| Application | Motorcycle parts, auto parts, Power Tools parts, Motor parts, electric Bicycle, |

Why Powdered metals?

Significant cost savings.Create complex or unique shapes.

No or minimal waste during production.

High quality finished products.

Strength of materials

Production process of powder metallurgy

Powder mixing - Forming - Sintering - Oil impregnation - Sizing -Ultrasonic cleaning - Steam oxidation - Oil impregnation - Final inspection - Packing

Company Profile

JINGSHI established in 2007

Manufacturer & Exporter

Exacting in producing powder metallurgy gears and parts

Passed ISO/TS16949 Quality Certificate

Advanced Equipment

Numbers senior R & D engineers and Skilled operators

Precise Examination Instruments.

Strict Quality Control

With the "More diversity, More superior, More professional " business purposes, we are committed to establish long-term friendship and win-win relationship with domestic and international customers to create a bright future .

Certification

Please Send us your 2D or 3D drawings to start our cooperation!

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23