Magnetic Coupling for Gear Pumps

Fujian Renhao Plastic Technology Co., Ltd. / 2022-06-27

- Shaft Hole:10-32

- Torque:3~80nm

=== Base Info ===

- Bore Diameter:19mm

- Speed:10000r,M

- Structure:Rigid

- Material:Stainless Steel

- Type:Universal Coupling

- Transport Package:Cartons

- Specification:As customer′s request

- Origin:China

- HS Code:8505111000

- Production Capacity:5000,Month

- Package size per unit product:35.00cm * 26.00cm * 16.00cm

- Gross weight per unit product:20.000kg

=== Description ===

Basic Info.

Bore Diameter 19mm Speed 10000r/M Structure Rigid Material Stainless Steel Type Universal Coupling Transport Package Cartons Specification As customer′s request Origin China HS Code 8505111000 Production Capacity 5000/MonthPackaging & Delivery

Package size per unit product 35.00cm * 26.00cm * 16.00cm Gross weight per unit product 20.000kgProduct Description

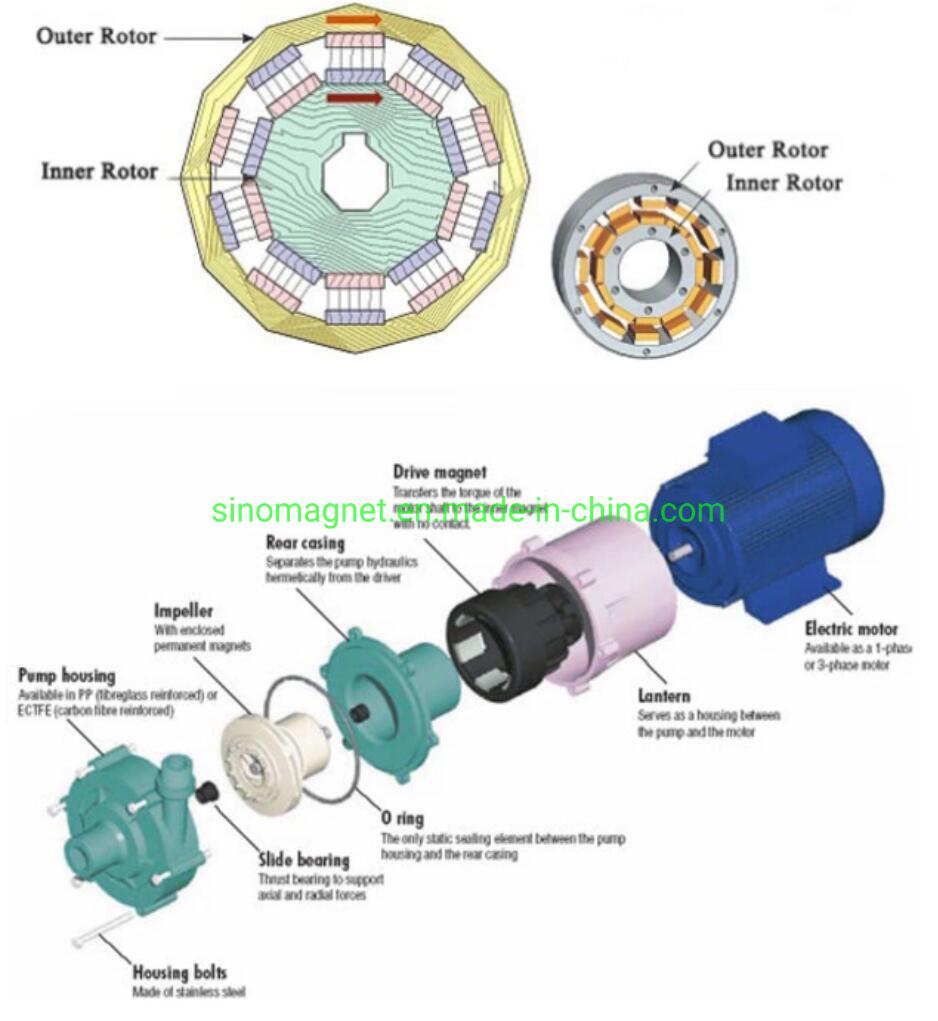

Permanent Magnetic coupling is a coupling that transfers torque from one shaft but using a magnetic field rather than a physical-mechanical connection.

While all magnetic couplings use the same magnetic properties and basic mechanical forces, there are two types that differ by design.

The two main types include:

- Disc-type couplings featuring two face-to-face disc halves embedded with a series of magnets where torque is transferred across the gap from one disc to the other

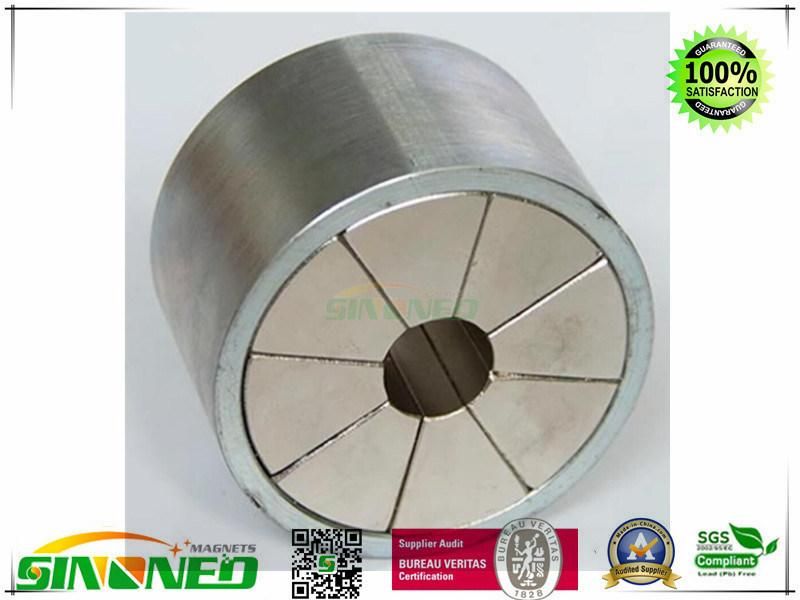

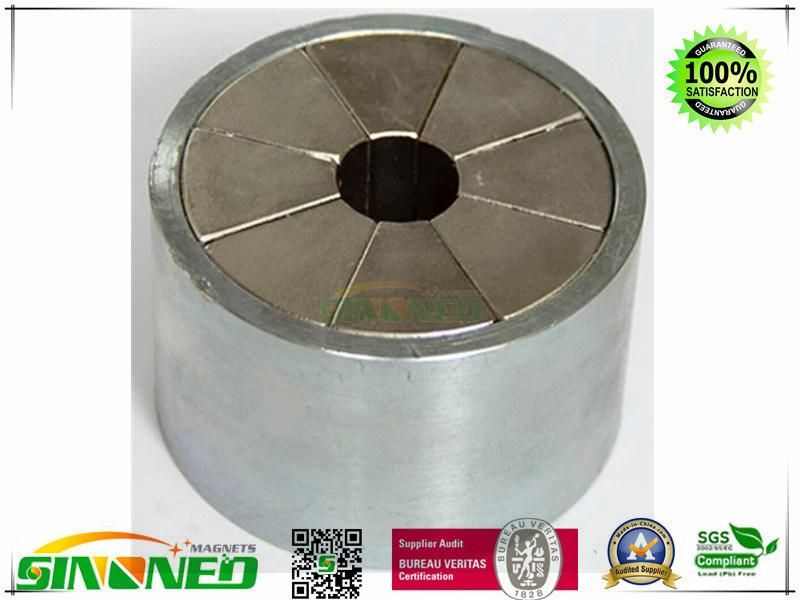

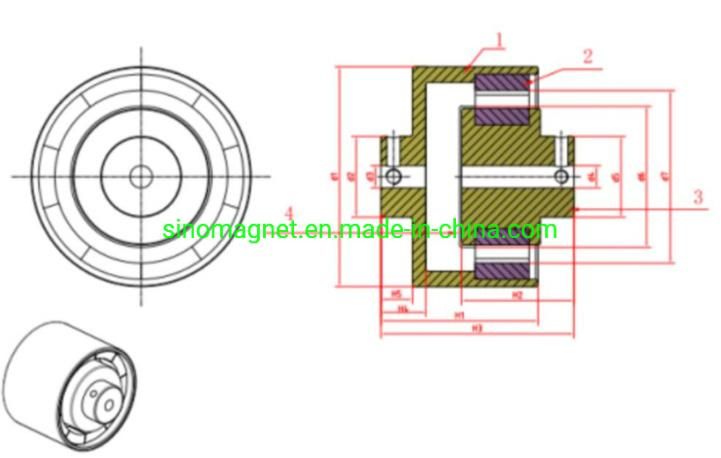

- Synchronous-type couplings such as permanent magnet couplings, coaxial couplings and rotor couplings where an internal rotor is nested inside of an external rotor and permanent magnets transfer torque from one rotor to the other

In addition to the two main types, magnetic couplings include spherical, eccentric, spiral, and nonlinear designs. These magnetic coupling alternatives aid in the use of torque and vibration, specifically used in applications for biology, chemistry, quantum mechanics, and hydraulics.

In the simplest terms, magnetic couplings work using the fundamental concept that opposite magnetic poles attract. The attraction of the magnets transmits torque from one magnetized hub to another (from the driving member of the coupling to the driven member). Torque describes the force that rotates an object. As external angular momentum is applied to one magnetic hub, it drives the other by transmitting torque magnetically between the spaces or through a non-magnetic containment barrier such as a dividing wall.

The amount of torque generated by this process is determined by variables such as:

- Working temperature

- The environment in which processing occurs

- Magnetic polarization

- Number of pole pairs

- Dimensions of pole pairs, including gap, diameter, and height

- Relative angular offset of the pairs

- The shift of the pairs

Depending on the alignment of the magnets and discs or rotors, the magnetic polarization is radial, tangential, or axial. Torque is then transferred to one or more moving parts.

Magnetic couplings are most often used for liquid pumps and propeller systems since a static, physical barrier can be placed between the two shafts to separate the fluid from the motor operating in air. Magnetic couplings preclude the use of shaft seals, which eventually wear out and fail from the sliding of two surfaces against each other. Magnetic couplings are also used for ease of maintenance on systems that typically require precision alignment when physical shaft couplings are used since they allow a greater off-axis error between the motor and driveshaft.

Item | Description |

1 | Outer Rotor |

2 | Magnet |

3 | Inner Rotor |

4 | Spacer Sleeve |

1. Materials

Magnet: Neodymium Magnet

Sleeve: Austenite stainless steel, such as SS304, SS316.

Main part: 20# steel, martensitic stainless steel

2. Advantages

Magnetic coupling for standard applications

Hermetically sealed

No contact of torque transmitting elements

No maintenance necessary

High efficient can optional

3. Recommended applications

-Chemical industry

-Oil and gas industry

-Refining technology

-Pharmaceutical industry

-Centrifugal pumps

-Top drive mixers/agitators

4. How does magnetic coupling work?

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23