Mc Nylon Plastic Transmission Gear Custom Self-Lubricating Nylon Gear

WuHan LanYuan Protective Co., Ltd. / 2022-06-27

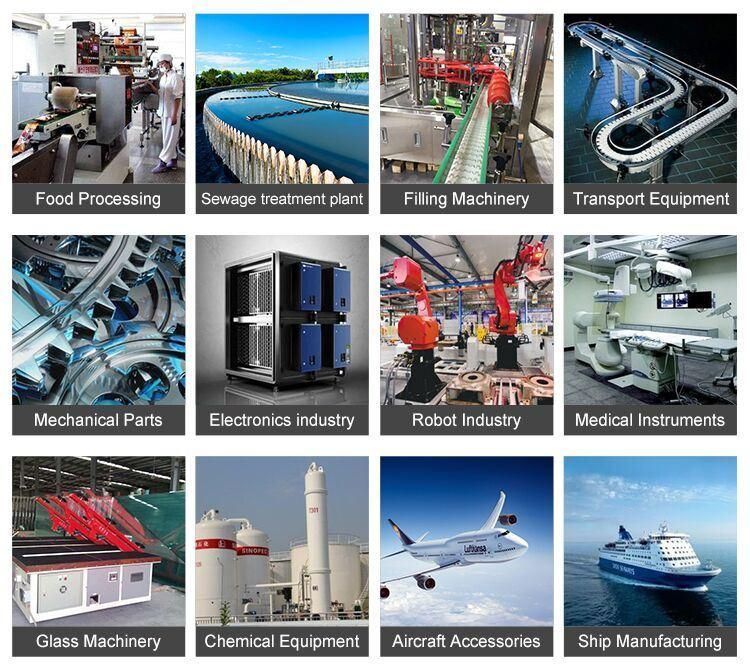

- Application:Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car

- Hardness:Hardened Tooth Surface

- Gear Position:External Gear

- Manufacturing Method:Cut Gear

- Toothed Portion Shape:Spur Gear

- Material:Nylon

=== Base Info ===

- Model NO.:c-34

- Type:Customized

- Transport Package:Wood Case

- Specification:customized

- Trademark:gz-plastic

- Origin:China

- Production Capacity:300pieces,Months

=== Description ===

Product display

Product display

Product display

Product displayA professional team with 10+ years of technical experience is at your service

Certification certificate

Certification certificateCompanies strictly enforce the ISO9001(2008)international quality certification system, the product quality conforms to the

eu RoHS standard.

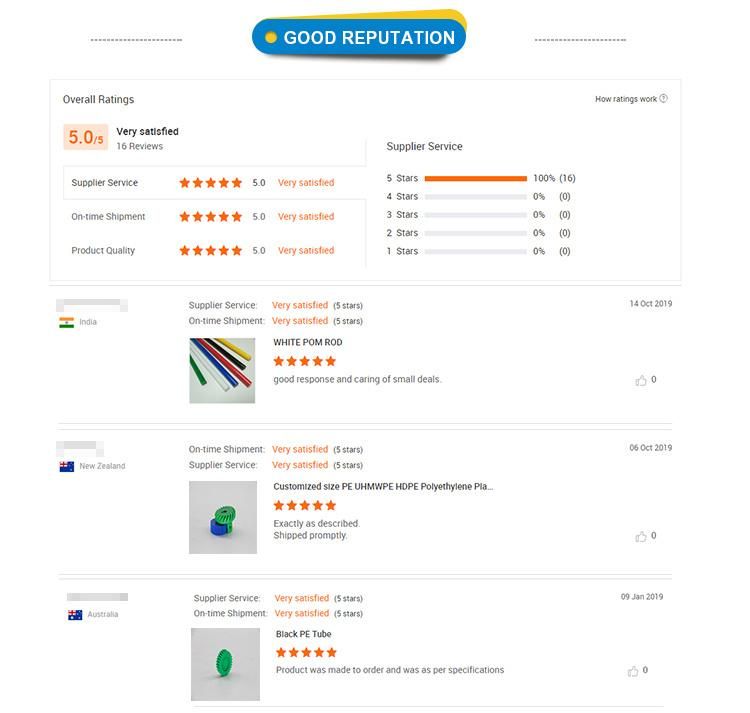

Professional team

Professional teamThe company has professional product technical consultation and after-sales service;Good market reputation (quality

assurance, reasonable price, timely delivery!)We will wholeheartedly provide you with the best quality products, the most

thoughtful service!

Guangdong Engineering Plastics Industries Co., Ltd! We have the professional engineer teams and sales teams, and we

have technology and experiences in engineering plastic industry for morethan 15 years! Our company is located in Huangpu

District, Guangzhou City, China, where the logistics is developed! With the rich experiences and technology for manufacture,

design, research and development ability, support personalized customization. We have full set of high efficiency producing

equipment and advanced numerical control machines, such as: molding injection machines, CNC molding manufacture

machines, fine carving machines, Horizontal lathes, milling machines. We can customize all kinds of Engineering plastics

products according to our customers'drawings or samples.

Our factory

Our factorySpecializing in the production of "engineering plastic accessories" of high-tech enterprises, the company has a set of

imported production equipment and CNC processing equipment, processing means advanced, strong technical force.

Our strength

Our strengthThe company has rich experience, strong strength and participated in many high-end exhibitions;Many partners from other

countries are visiting

cooperation

cooperationCooperate with many well-known companies

Purchase order

Purchase orderQ1. We don't have drawings, can we produce according to the samples we provide?

A1. OK

Q2. How to customize plastic parts?

A2. Customized according to drawings

Q3. Can I make a sample for testing first?

A3. OK

Q4. How long is the proofing cycle?

A4. 2-5 days

Q5. What are your processing equipment?

A5. CNC machining center, CNC lathe, milling machine, engraving machine, injection molding machine, extruder, molding

machine

Q6. What craftsmanship do you have for processing accessories?

A6. According to different products, different processes are used, such as machining, extrusion, injection molding, etc.

Q7. Can injection products be surface treated? What are the surface treatments?

A7. OK. Surface treatment: spray paint, silk screen, electroplating, etc.

Q8. Can you help assembling the product after it is made?

A8. OK.

Q9. How much temperature can the plastic material withstand?

A9. Different plastic materials have different temperature resistance, the lowest temperature is -40ºC, and the highest

temperature is 300ºC. We can recommend materials according to the working conditions of your company.

Q10. What certifications or qualifications does your company have?

A10. Our company's certificates are: ISO, Rohs, product patent certificates, etc.

Q11. How scale is your company?

A11. Our company covers an area of 2,000 square meters and has 100 employees.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23