P4.81 High Brightness Full Color Outdoor Rental LED Video Wall

Guangzhou Zhonghao Packaging Products Co., Ltd. / 2022-06-27

- Tube Chip Color:Full Color

- IP Rating:IP65

- Pixel Pitch:4.81mm

- Pixel Configuration:1R, 1G, 1B

- Display Function:Video Display

- Average Power Consumption:300W , m²

=== Base Info ===

- Model NO.:BST-P4.81-OR

- Pixel Density:43264 Pixels,Sqm

- Scanning Mode:1,6

- Display Type:LED Video Display

- Application:Stage Performance

- Certification:CE, RoHS, CCC

- Warranty:2years

- Delivery Time:20 Working Days

- Brightness:>5000nits

- Refresh Rate:>2000Hz

- OEM:Yes

- Size:500X500mm

- Color:Full Color

- Material:Die-Casting Aluimnum

- Transport Package:Flight Case

- Specification:CE, ROHS, ISO9001

- Trademark:BST

- Origin:Shenzhen, China

- HS Code:8528591090

- Production Capacity:3000sqm,Month

=== Description ===

LED Display Series

BST-ORD-3

BST-ORD-4

BST-ORD-6

Pixel Pitch(mm)

3.91

4.81

6.25

Pixel Density(dots/m2)

65536

43264

25600

Avr Power Consumption (W/M2)

≤500

≤500

≤500

Brightness Max(cd/m2)

≥6500

≥6500

≥6500

Color Temperature(after calibration)K

6500

6500

6500

Cabinet Material

Die Casting Aluminum

Die Casting Aluminum

Die Casting Aluminum

Weight(kg/Panel)

16

16

16

Working Humidity

10%-95%

10%-95%

10%-95%

Driving Method

1/8

1/13

1/10

LED Type

SMD2525

SMD2727

SMD3535

Horizontal/Vertical Viewing Angle(º)

H140º/V140º

H140º/V140º

H140º/V140º

Recommended Viewing Distance(m)

1--100

1-100

1--100

Power Supply

Single power

Single power

Single power

Refresh Rate(Hz)

≥1920

≥1920

≥1920

Weight(kg/m2)

40

40

40

Grey Scale(bit)

R'G'B 16bit

R'G'B 16bit

R'G'B 16bit

Frame Rate(Hz)

50/60

50/60

50/60

Life Time(H)

≥100000

≥100000

≥100000

Protection

Outdoor

Outdoor

Outdoor

Cabinet Size(W*H)(mm)

500X1000

500X1000

500X1000

LED Chip

Epistar

Epistar

Epistar

Contrast

2000:1

2000:1

2000:1

Protection

IP65

IP65

IP65

Max Power Consumption(W/M2)

900

900

900

Working Temperature

-20C°/40C°

-20C°/40C°

-20C°/40C°

Module Size(W*H)(mm)

250X250

250X250

250X250

Driving Chip

MBI5124

MBI5124

MBI5124

Control Input

DVI/HDMI/HDSDI

DVI/HDMI/HDSDI

DVI/HDMI/HDSDI

Max Hanging(Vertical)

≥200kg

≥200kg

≥200kg

a. Aging

1. 100% fully test

2. Condition: 72 hours with 256 grey level

b. Vibration Testing

Condition: 3-5 mins up and down in 5mm range

Factory Equipment

Wave Soldering Conveyor, PC Console, Wave Soldering Machine,

Automatic Glue- pouring Machine, Solder Paste Printing Machine,

Reflow Soldering Machine, Automatic Solder Paste Printing Machine,

Withstand Voltage Tester, Ground Resistance Tester,

Medium-speed Automatic SMT Machine, Super Mute Terminal Machine,

Automatic Wire Stripping Machine, Automatic Optical Inspection (AOI) Equipement.

Package

Flight case and Fumigation-Free wooden case

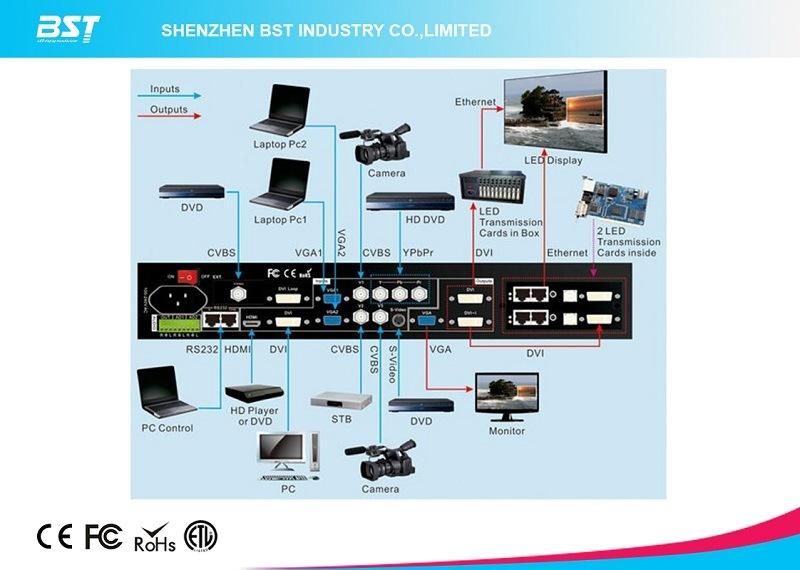

Control System Connection

Competitive Advantage:

1. 24/7 Online support service

2. Free onsite maintenance / Year

3. Solution design

4. Free online training any time

5. High quality raw material used like neutrik flight connector, MBI IC etc.

Why Choose us?

BST has a perfect service system, including pre-sale service, in-sale service and after-sale service. To provide high quality service for our customers, we train every salesman with necessary product maintenance knowledge and organized a Technology Supporting Department with a group of excellent and professional engineers. Any problem you can contact us at any time you like.

Pre-sale service:

1. Reply enquiries in 24 hours.

2. Market research and forecast for customer.

3. Provide unique and professional solutions based on customer's requirement.

4. Data sheet and samples offer.

5. Other services, such as special packing design, factory visiting and so on.

In-sale service:

1. Tracking report in producing.

2. Quality test report for every order.

3. Photos and videos as per customer's requirement.

4. Free spare parts.

After-sale service:

1. Lifetime free maintenance and upgrade.

2. Complaint respond period not exceed 24 hours; maintenance guidance and problem solution supplied in 48 hours.

3. Customer satisfaction tracking report.

4. Free technician training.

5. Full set of documents free of charge, which including installation guidance, software operation manual, easy maintenance manual and control system software CD and so on.

6. Special service for big project, such as stadium, exhibitions, squares and so on.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23