Custom Making Assembled Separated Plastic Gear

Qingdao Honest Environmental Protection & Technology Co., Ltd / 2022-06-27

- Application:Motor, Electric Cars, Machinery, Marine, Toy, Agricultural Machinery, Car

- Hardness:Hardened Tooth Surface

- Gear Position:External Gear

- Manufacturing Method:Cast Gear

- Toothed Portion Shape:Spur Gear

- Material:Plastic

=== Base Info ===

- Model NO.:customized plastic gear

- Type:Bevel Gear

- Item:Custom Plastic Gear

- Color:Black,White,Red,Green,Transparent or Any Color

- Technology:Hot Pressing Molding ,Injection Molding or Extrusi

- Working Temperature:-60 to +350 Degrees Celsius

- Density:1.0-2.0

- Drawing Format:Dwg,Dxf,Igs,Step,X-T and Pdf

- Tolerance:+,-0.05mm

- Service:OEM or ODM

- Free Samples:1-5 PCS

- Transport Package:Carton Case or Upon Request

- Specification:as Per Drawing

- Trademark:Baimi

- Origin:China

- HS Code:8477900000

- Production Capacity:50000,Day

=== Description ===

Basic Info.

Model NO. customized plastic gear Type Bevel Gear Item Custom Plastic Gear Color Black,White,Red,Green,Transparent or Any Color Technology Hot Pressing Molding ,Injection Molding or Extrusi Working Temperature -60 to +350 Degrees Celsius Density 1.0-2.0 Drawing Format Dwg/Dxf/Igs/Step/X-T and Pdf Tolerance +/-0.05mm Service OEM or ODM Free Samples 1-5 PCS Transport Package Carton Case or Upon Request Specification as Per Drawing Trademark Baimi Origin China HS Code 8477900000 Production Capacity 50000/DayProduct Description

Custom making assembled separated plastic gear

Production Show for plastic gear

We can custom shape,size,color material and quantity for plastic gear / plastic sprocket / plastic rack pinion as your requirment.

Products Specification for plastic gear

| Item | Custom making assembled separated plastic gear |

| Application | 1.Power transmission system part for industrial equipment ,agriculture equipment ,etc 2.Gear Part for medical device, automotive, office equipment, household 3.Gear part for appliances,digital electronic, toy etc. |

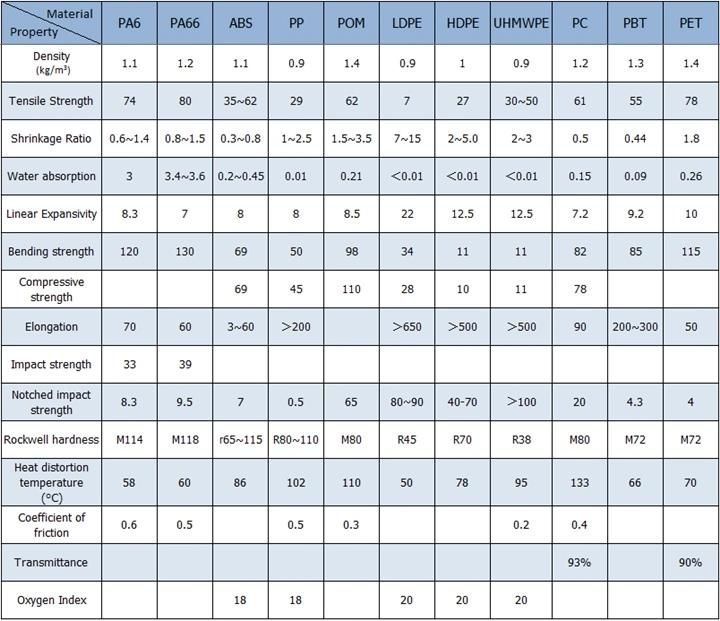

| Material | PA , Nylon , MC nylon , POM ,ABS ,Pa 6 , Pa 66 , PU ,PP , PE ,PTFE ,UHMWPE, HDPE ,LDPE , PVC , Polyurethane ,Urethane , Polyamide , etc. |

| Size | As per customer's request ( Mini , Minature ,Small , Big , Large , Giant ) |

| Color | Black, white, red, green or according to Pantone code |

| Type | spur gear , worm gear , bevel gear , helical gear , conical gear , rack gear , ring gear , cylindrical gear , pinion gear , sprocket gear , star gear , planetary gear , other gears for power transmission parts |

| Finish | High Gloss,Fine Grain,Electroplating,Painting,Printing,Texture etc,or as request |

| Production basis | Samples or drawings |

| Density | 1.0-2.0g/cm³ |

| Hardness | 30-120 Shore D |

| Working temperature | -60~350ºC |

| Processing Technic | CNC machining , injection molding & casting mold , etc |

| Tolerance | ±0.05mm |

| Conductivity | Conductive or insulative |

| Certification | ROHS,FDA,ISO9001:2000 |

| Working life | 1-30 years |

| Service | OEM or ODM (Debossed,embossed,printed logo or as request) |

| Free samples | 1-5 pcs |

1.Good abrasion, heat and oil resistance.

2.Good anti-aging performance and gas tightness.

3.Ease of bonding to other material.

4.Excellent oxygen and ozone resistance.

5.Non-flammable,self-extinguish.

6.Customer's design and logo;

7.Small order acceptable;

8.Free samples;

9.100% raw material;

10.Variety of material;

11.Various hardness for your choice.

12.High precision & high quality control;

13.Competitive prices;

14.Safe packing & prompt delivery

| Lead Time: | Rubber products: 3-7 days after payment Plastic products: 5-7 days after payment CNC machined parts: 3-10 days after payment |

| Packaging & Shipping: | All the goods will be packed well before shipping. They will be shipped by sea,by air or by express according to the weight, the volume, or the customer's requirement |

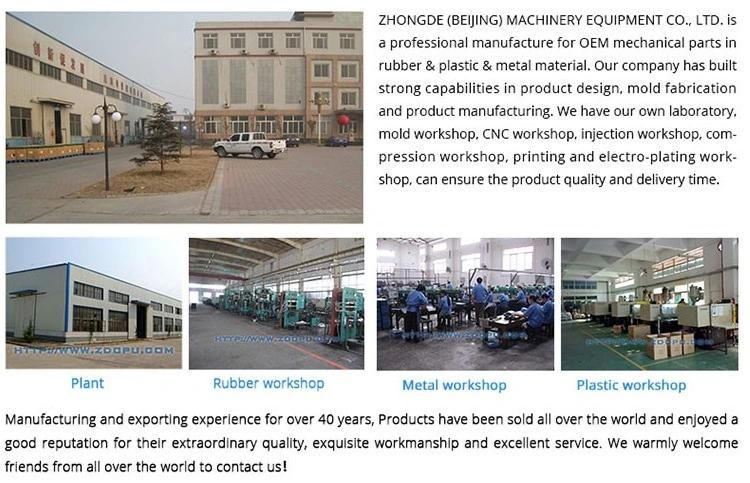

Company Information:

| Rubber & Plastic workshop | Our work shop have own advance producing line for rubber & plastic products, which will make sure for quality and lead time. |

| Mold workshop | We have our own workshop to make sure mold precision and lead time. |

| CNC workshop | We introduced DMG (Deckel Maho Gildemeister) from Germany for precision and production capacity. |

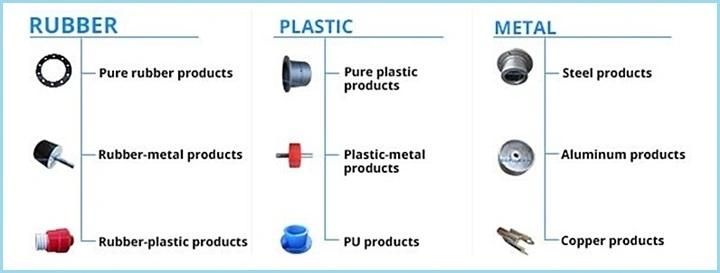

Factory Main Products

We can provide OEM service,which means producing base on your drawings or samples,also we can design according to its application or customer`s requirments.

Order Operation Flow

We execute each step according to the operation process flow, strictly, seriously and meet the requirements of customers with good quality on time.

For Fast Quotation,Please Inform Below Details

1. What production you need to custom?

2. Which kind plastic or rubber material you prefer to use? (plz let us know the using environmental)

3. Size details for your custom request? (plz provide drawings or samples for refference)

4. Quantity request

5. Prefer color

Welcome to leave your inquiry,we will feedback to you during 12 hours!

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23