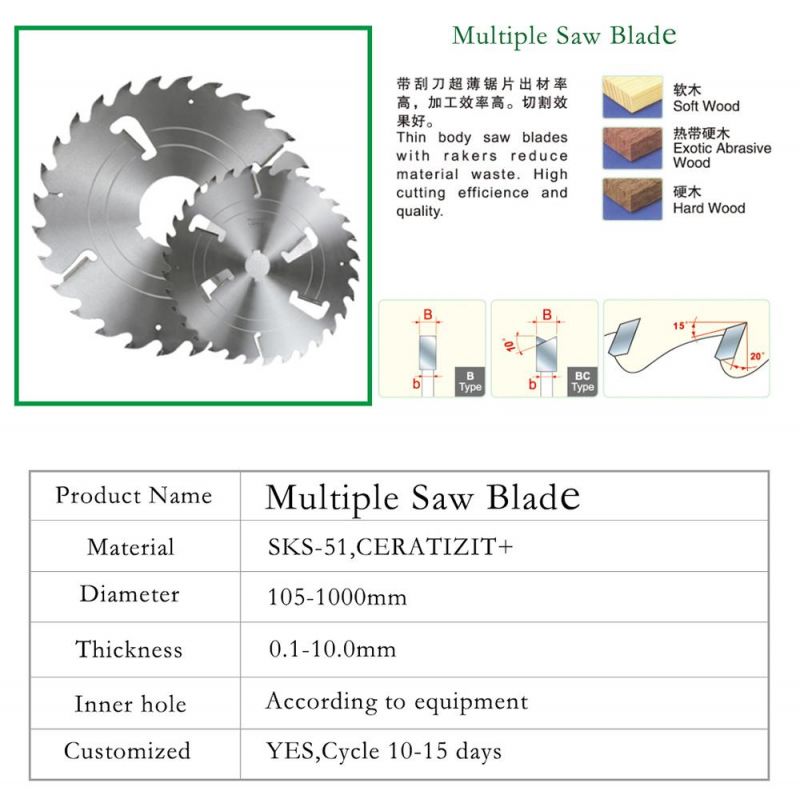

Carbide Multi Rip Saw Blade with Scraper / Wipers / Keyway

Fuzhou Haomin Imp. & Exp. Co., Ltd. / 2022-06-09

- Certification:ISO9001:2008, ISO9001:2000

- Tooth Form:Zy Tp

- Diameter:105-1000mm

- Function:Cutting

- Shape:Circular Saw Blade

- Coating:as Shown or Customized

=== Base Info ===

- Type:Carbide Saw Blade

- Model No:105-1000mm

- Thickness:0.1-10mm

- Quality Grade:Professional Grade

- Application:Cutting Wood

- Customized Support:OEM, ODM, Obm

- Transport Package:Carton or Blister Packing

- Specification:customization

- Trademark:as show or customization

- Origin:China (Mainland)

- Production Capacity:5000000,Year

=== Description ===

Basic Info.

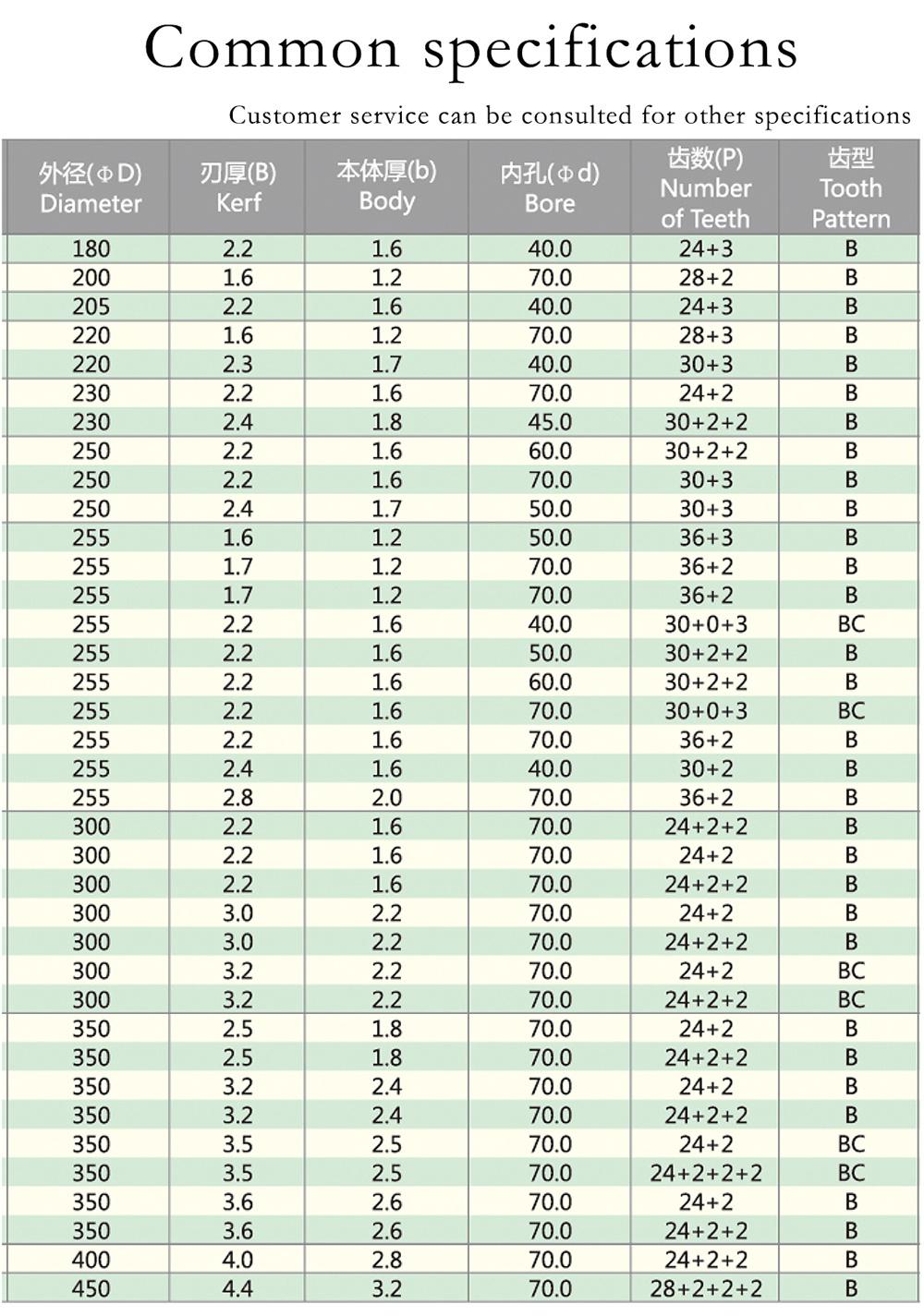

Type Carbide Saw Blade Model No 105-1000mm Thickness 0.1-10mm Quality Grade Professional Grade Application Cutting Wood Customized Support OEM, ODM, Obm Transport Package Carton or Blister Packing Specification customization Trademark as show or customization Origin China (Mainland) Production Capacity 5000000/YearProduct Description

The characteristics of1,Tooth type is left and right teeth..

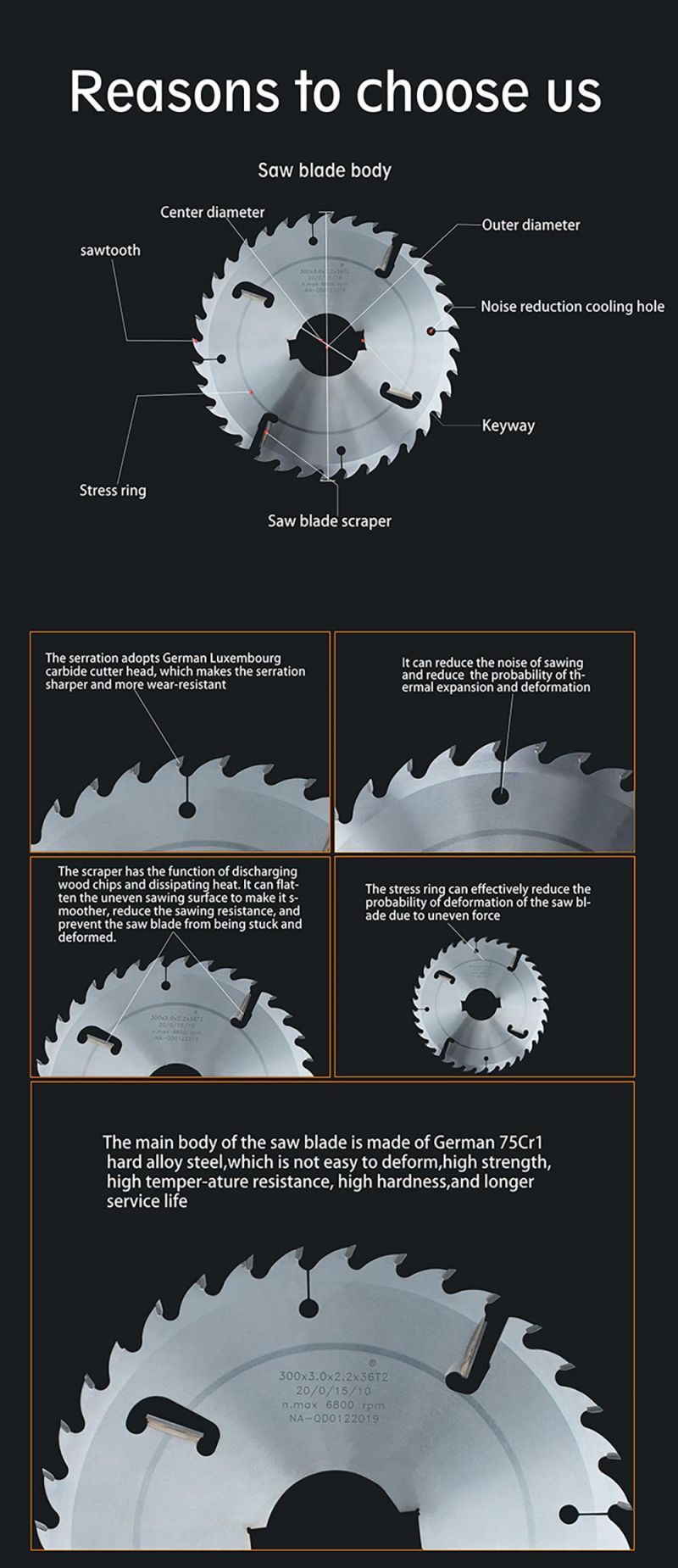

2, saw blade body design has bullet-proof design, suitable for longitudinal cutting all kinds of dry hard and hard wood and tree node.

3, no burning sheet, the cut surface is smooth.

4, for customers used for expensive materials, can save a certain loss, improve the sampling rate.

5, used for multi blade saw, push table saw, table disc saw.

6.Non-standard saw blades can be customized according to customer needs

Apply to:Longitudinally cut all kinds of wood, hard and dry and knotted

style:multi-blade saw blade with scraper/alloy saw blade/ultra-thin multi-blade saw blade

How to prevent woodworking multi - saw saw blade burning?

Multi-blade saw blade burning is a common problem encountered in wood processing plants, and it is not easy to solve the problem completely: the quality of saw blade directly affects the efficiency of processing and the quality of products. One of the worst accidents with multiple saws resulted in burning the saw blades. Burning saw blade directly leads to the scrap of saw blade and affects the working process.

Analysis of the main reasons for multi-blade saw burning:

1, heat dissipation is not good. It is best to buy a saw blade with a cooling hole, perhaps to add water or other coolant to drop the temperature.

2. Too many teeth. Because of the large number of blades, the resistance of multi-blade saw is large. The more teeth, the greater the resistance, and the easier it is to burn the saw blade.

3, secretion is not smooth. Sawdust is not simply discharged will also form part of the too hot, the saw blade must have an outstanding secretion system.

4. Raw materials. Particleboard original is very not simple saw. If the particleboard quality is too poor, too many impurities will simply burn the saw blade.

The following parts need to be checked in practice.

First: Check if the sink is blocked

Second: check whether the water is sufficient

Third: check whether the spindle is misplaced

Fourth: check whether the navigation axis and the main axis are in the same plane

Fifth: check whether the feeding chain is balanced with the saw blade

Check and make adjustments accordingly.

Many pieces of saw blade quality is uneven, we must choose high-quality pieces of saw blade, do not buy cheap poor quality saw blade, that not only delay production time, but also can cause mechanical accidents.

FAQ:1. What terms of payment are acceptable?

A: Normally we accept L/C, T/T and Western Union.

2. How can we be your agent in our country?

A: Please inform us your detailed company, we will discuss and propose helpful suggestion for you, and to find the best solution for you.

3. Do you offer free samples?

A: Normally we do not offer free samples, but we could properly adjust according to detailed requirement.

4. How is your quality?

A: We have a very seriously control system. We guarantee the high performance of our products.

5. When you can reply to me when I send you an Inquiry?

A: We promise to reply within 24 hours( including holidays) on receipt of your inquiry.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23