Factory Customized Painting Equipment Spray Booth Car Paint Booth

Wenzhou Longwan Haibing Welton Machinery Fittings Factory / 2022-06-23

- After-sales Service:1year

- Warranty:1year

- Type:Coating Production Line

- Certification:CCC, CE

- Substrate:Steel

- Brand:Jzj

=== Base Info ===

- Model NO.:JZJ-FB-8

- Coating:Painting

- Airflow Direction:Fully Undershot-type

- Heating Mode:Diesel

- Paint Mist Treatment:Dry-type

- Condition:New

- Standards:Australia and New Zealand

- Dimension:8 X 4 X 2.8

- Heating System:Diesel Oil or Gas

- Transport Package:Normal Package Suit for Ocean Shipping

- Specification:8*4*2.8

- Trademark:JZJ

- Origin:Jiangsu China

- HS Code:8419899090

- Production Capacity:3000sets, Year

=== Description ===

Our Service

1. 24 months warranty time

2. Customization accepted

3. OEM accepted

4. Detailed installation drawings and video will be provided. If needed, we also have special experienced installing staff can go abroad to help customers install and check spray booth.

5. Prompt after-sale service. We have established perfect after-sale service system. If needed, our staff will arrive in 72 hours to repair products.

If you have interest in any of our products, please kindly contact us. If you have any questions or doubts, please also feel free to contact us.

Q: What standards are you carrying out for your products?

Q: What standards are you carrying out for your products?A: We produce according to the ISO 9001 and ISO 14001 rules.

Q: How to install the machine?

A: We will arrange 1-2 engineers to your factory to guide installation and assembly.

Q: What is your international market?

A: We have exported our products to about 50 countries and regions worldwide, such as the US, France, Singapore, Australia, the Middle East, Germany, Japan, Russia, Sweden, Finland and more

Q: What is your productivity?

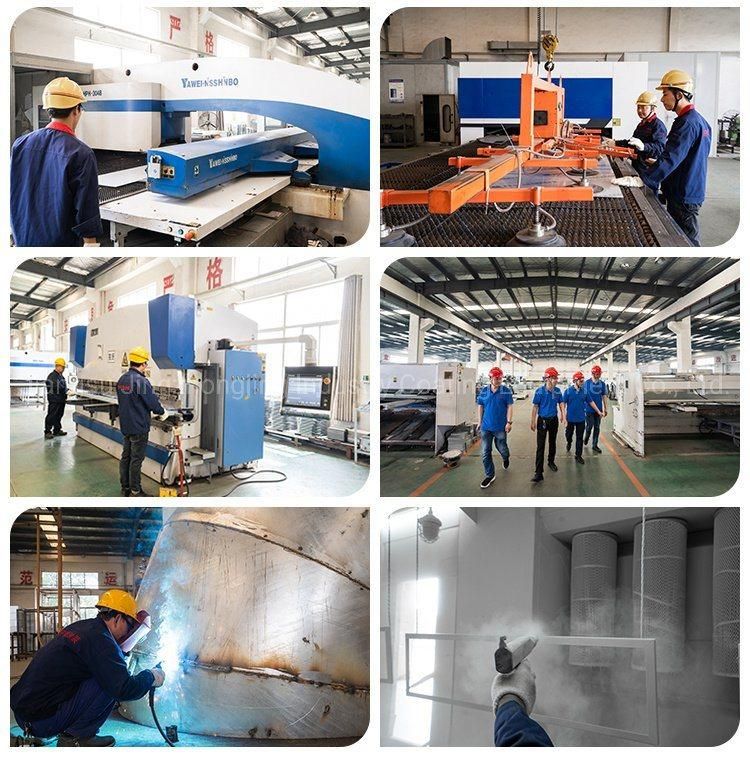

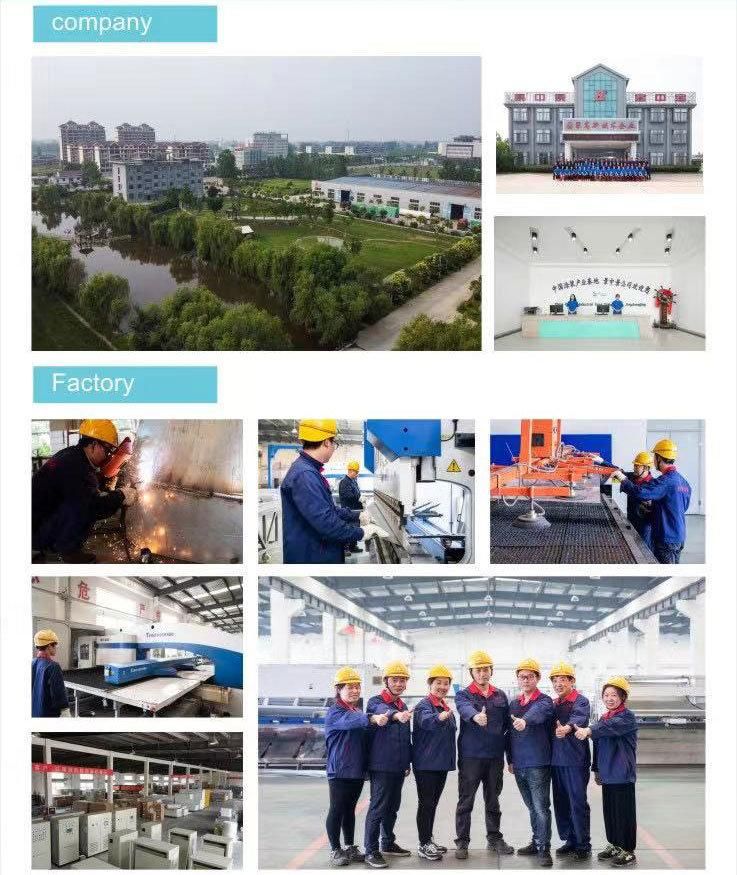

A: We have two production basement - Jiangsu Jingzhongjing Industry Coating Equipment Co. Ltd and Guangzhou Jingzhongjing Industrial Painting Equipment Co. Ltd. We are specialized in automobile spray booth, automobile metal collision painting line, prep-station, shower test booth, sand blasting booth, shot blasting machine and more.

Our yearly productivity is 2,500 sets spray booth, so we can send you products quickly.

Q: Do you have the right to export?

A: Yes, we are registered in the customs and gained the right to export by ourselves.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23