Carbide End Mills for Cutting Aluminum Alloy and Copper

Shandong Welink Packaging Co., Ltd. / 2022-06-09

- Coating:Coating, Uncoated

- Tooth Form:Spiral Tooth

- Tooth Space:Standard

- Structure:Integral

- Material:Carbide

- Type:Milling Cutter

=== Base Info ===

- Model NO.:Aluminum End Mills

- Process Usage:Metal-Cutting CNC Machine Tools

- Movement Method:Contour Control

- Control Method:Closed-Loop Control

- Numerical Control:CNC,Mnc

- Performance Classification:High-End CNC Machine Tools

- Certification:ISO 9001

- Condition:New

- Application:Copper

- Diameter:1-20mm

- Helix:45,55 Degree

- Length:50-150mm

- HRC:55

- Samples:Available

- OEM:Accept

- Transport Package:1PC in a Plastic Tube, 10PCS in a Group

- Specification:SGS

- Trademark:Hiboo

- Origin:Changzhou Jiangsu China

- HS Code:8207709000

- Production Capacity:50000PCS,Month

=== Description ===

Overview

Product Description

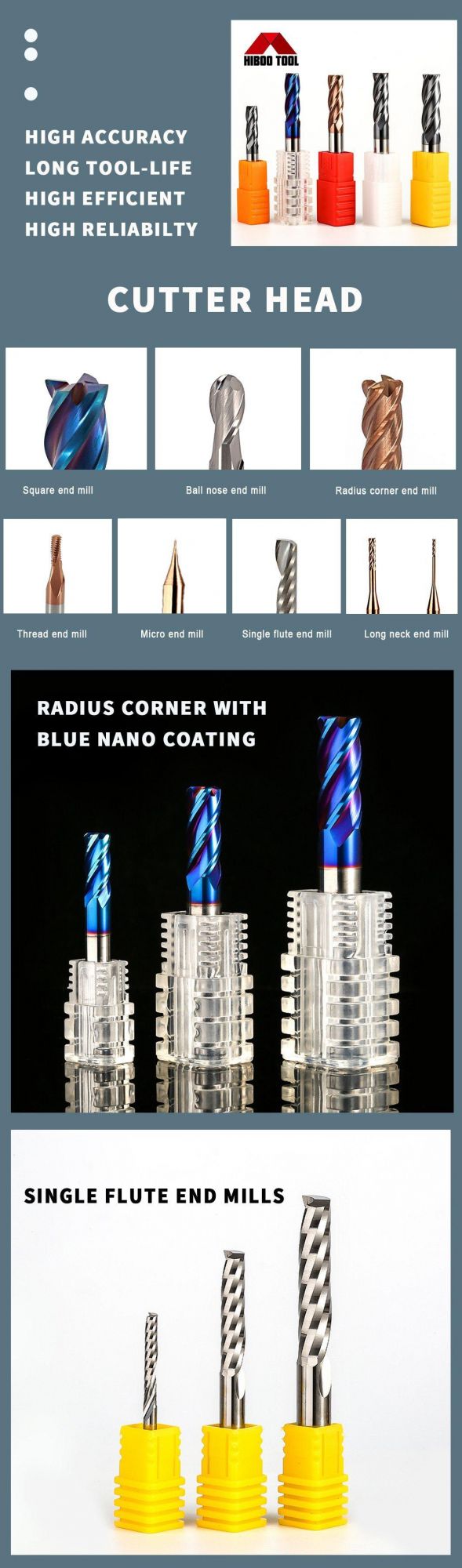

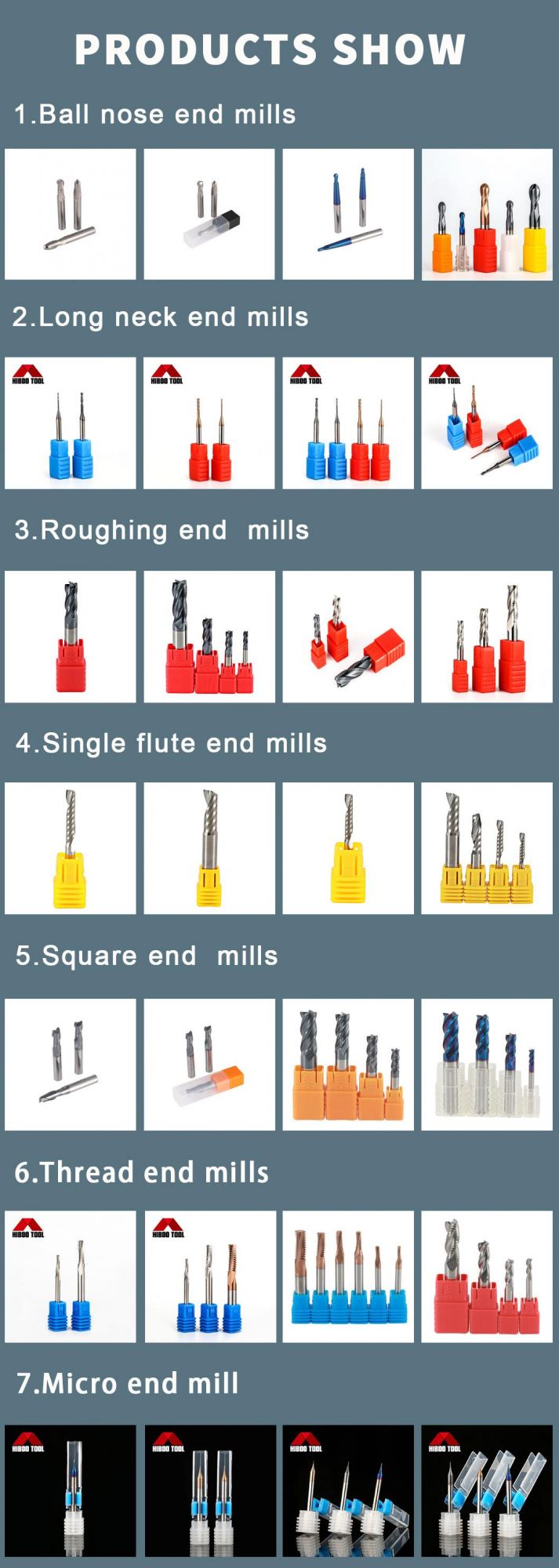

HRC55 3Flutes carbide end mills for cutting Aluminum

1. HRC55 carbide raw Material

Order No

Packaging & Shipping

Packaging & Shipping6. Package and shipping details

Laser brand on the cutter's shank , 1 pc in a plastic tube , 10pcs a group7.Delivery Time

For samples , we dispatch your tools in 2-7 workdays .

For formal orders,We delivery tools to you in 7-30 workdays , it will depond on your order quantity .

8. Payment Term

T/T ,Western Union , MoneyGram,L/C Company Profile

We located In Changzhou City, About 1 Hours from Shanghai, China. We has committed to manufacturing solid carbide end mills, Drills, reamers, Inserts, Both standard and Nonstandard tools, offering high quality cutting tools, competitive price and unequaled customer service.

Our carbide cutting tools For the medical fields including Orthodontics, Orthopedics, Catheters, and Surgical instruments; For the automotive parts and engines, motorcycles, snowmobiles, and bicycle industries; For pattern and mold makers; For general manufacturing in marine, recreational and consumer products industries; For the plastics industry, and For the woodworking industry.

Efficient workshop and 5AXIS grind machines run by skillful operators. We have our partners as complementarities sited around our factory in 5 Km who is product turning tools, holder And others, they are all around our factory in 5 Km. So, you can trust us that we must satisfy your needs.

We earned reputation of good quality, Fast producting, Delivery in time, reliable service. Hiboo will continue to introduce some new series of tools to meet different requirements. Sincerely Welcome to inquiry products and visit our company, thanks.

Our Advantages

Our Advantages9.Why Choose Hiboo Tools

Several years' professional producting and exporting experienceAdvanced RD department meet your special demands

High precision CNC machines,high standard and strict inspection

Custom demand are welcomed ,OEM and ODM Service

All payment terms supported

Fast delivery time and Convenient Transportations

More than 20000 products are available

For your suggestions or complaints,We will handle them Soonest

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23