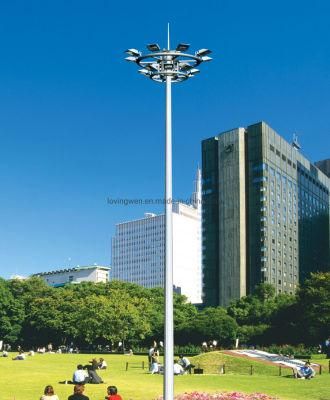

IP66 High Quality Outdoor 30m Q345 Steet High-Mast Lights

Yantai Changyou Glass Co., Ltd. / 2022-06-27

- Light Source:Sodium Lamp

- Color Temperature(CCT):Pure White

- Lamp Body Material:Aluminum

- Lamp Power:1000W 2000W

- Power Supply:DC

- Average Life:>8000h

=== Base Info ===

- Model NO.:BD-0123

- Application:Highway, Square, Garden

- IP Rating:IP65

- Certification:CE, RoHS, CCC, UL, FCC, CQC

- Voltage:220V

- Projection Distance:80m

- Pole Height:25-30m

- Transport Package:Cartoon or Crate

- Specification:18m - 30m

- Trademark:LUYOU

- Origin:Yangzhou

- HS Code:94054090

- Production Capacity:1000 Pieces Per Month

=== Description ===

Height

From 18 m to 50m

Suit for

Airport ,seaport,plaza,stadium ,square,highway station,street way ,etc

Shape

round or polygon

Material

Q345B/A572,minimum yield strength>=345n/mm2

Q235B/A36,minimum yield strength>=235n/mm2

Torrance of dimension

+- 2%

Lighting Source

400 W- 5000 W high pressure sodium flood light,light extension :up to 30 000 m²

Light plate

Various figure of selection ,material with hot dip galvanization steel frame

Lifting system

Lifter fixed in the inner of the pole with lifting speed of 3~5 meter per minute

Equipped e;antiferromagnetism brake and break -proof device,manual operation applied under power cut

Electric appliance control device

Electric appliance box to be be the hold of the pole ,lifting operation could be 5 meter away from the pole through wire .Time control and light control could be equipped to realize full-load lighting mode and part lighting mode

Surface treatment

Hot dip galvanized Following ASTM A 123, color polyester power or any other standard by client required.

Joint of Poles

Insert mode,innerflange mode,face to face joint mode .

Design of pole

Against earthquake of 8 grade

Wind Speed

80 Km/Hour

Welding

We has past flaw testing.Internal and external double welding makes the welding in shape

Thickness

6 mm to 20 mm

Production Process

Raw material test→Cutting→Molding or bending →Welding (longitudinal )→Dimension verify→Flangewelding→Hole drilling→Calibration→Deburr→Galvanization or powder coating ,painting→Recalibration→Thread→Packages

Packages

Our poles as normal cover by Mat or straw bale at the top and bottom ,anyway also can following by client required

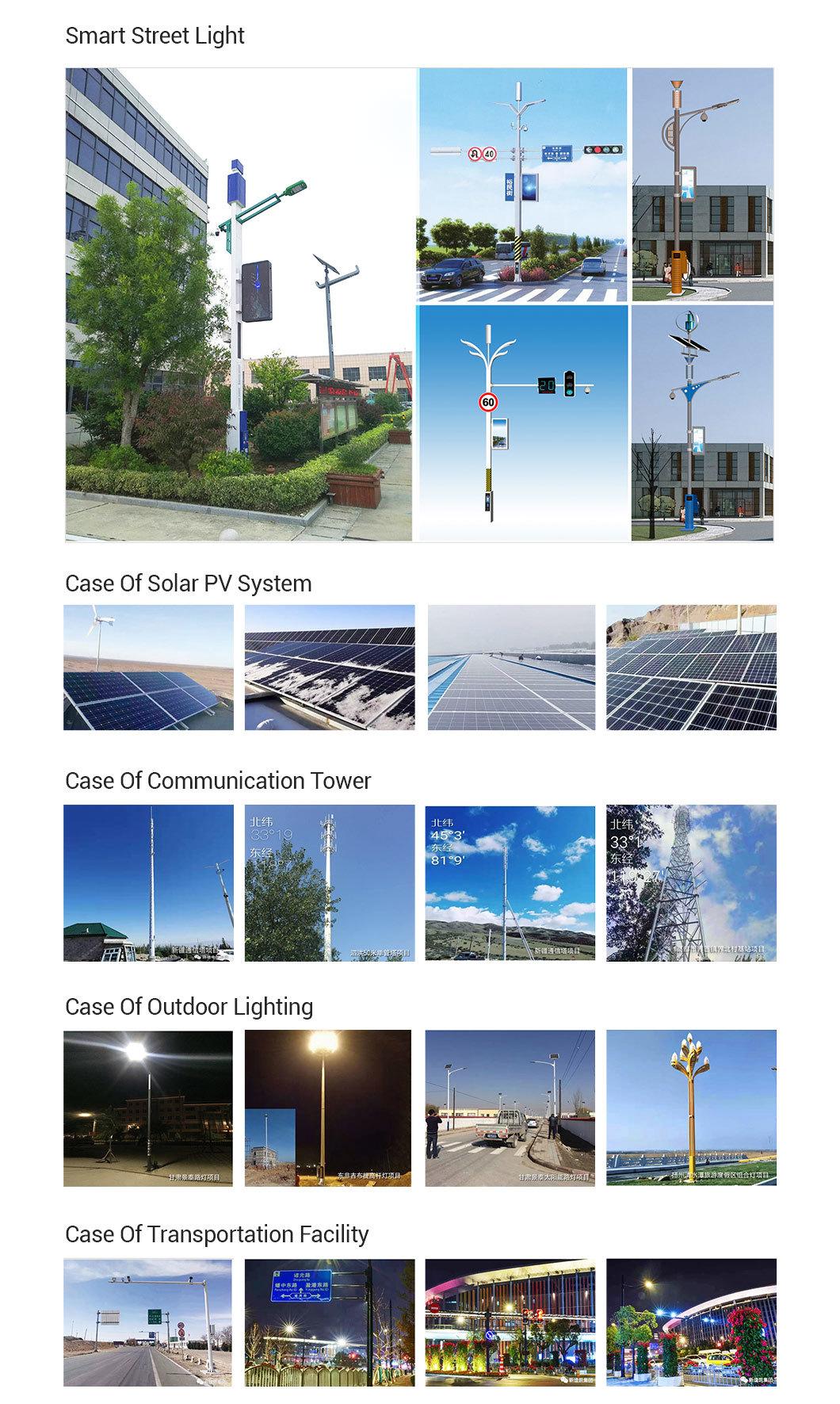

APPLICATIONS

Plaza High Mast Lighting

Airport High Mast Lighting

Highway High Mast Lighting

Storage-yard High Mast Lighting

Industrial-plant High Mast Lighting

Park High Mast Lighting

Dock High Mast Lighting

Stadiums High Mast Lighting

Overpass High Mast Lighting

Toll-station High Mast Lighting

Production Process

Raw material testCuttingMolding or bending Welding (longitudinal ) Dimension verifyFlangeweldingHole drilling Calibration Deburr Galvanization or powder coating, PaintingRecalibrationThreadPackaging

Packages

Our poles as normal cover by Mat or straw bale at the top and bottom ,anyway also can following by client required

Lifting system

Latch barrel with inner mounting bracket locker is mounted to an underside of the mast-top pulley assembly. Furthermore, all steel cables are not exposed and more effectively protected.

Latching mechanism latched on steering arms is able to release strain on steel cables when in the operation position. The process of latching on and off is stable and without vibration.

The bumper is designed on the luminary mounting bracket for avoiding direct damage between mast-top assembly and the raising luminary mounting bracket.

The leveling device for luminary support bracket is easy to operate and convenient to adjust level.

Special designed red-flag indicator has obvious visual effects and reflects actual situation of latching operation.

Testing

Packages:

Bulb wrappings for high mast lighting poles, individual cartons for lamps and controlling equipments, etc. A 40' HP loads 7-20M/ 6-25M/ 5-30M/ 4-35M high mast lights.

Our projects

Lead Time

20 days on receipt of payment for 10 high mast light poles

Payment Terms

30% in advance and 70% before shipment for our products

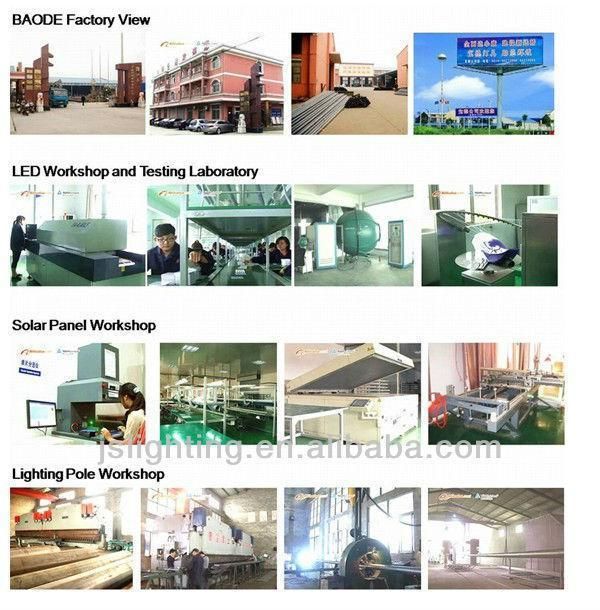

Company Information

Since 1998, we have started manufacturing street lighting. The 21 years' experiences have been a persuasive insurance for us to offer reliable products.

Large Factory with Complete Facility

We have 400 staffs with factory area 6000 m2. We also equipped with complete production and testing equipments, such as Steel Pole Rolling Machine, Spray Machine, Pressure Machine, Integrating Sphere, Lighting Simulating Machine and Weather-ability Testing Machines, etc . .

Our 60 experienced engineering team work with the PV institute of Shanghai FUDAN University , Shenzhen Foxconn to R&D outdoor lighting products. We have obtained over 20 national patents and built our own brand LUYOU.

Manufacturing main components to save cost. BAODE manufactures the solar panel, light fixture and pole to control the cost and quality.

Factory outlet. There's no middleman between the manufacturer BAODE and domestic and oversea buyers.

Send your message to this supplier

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23